A holographic polymer dispersed liquid crystal with high diffraction efficiency and low driving voltage and its preparation

A low driving voltage, dispersed liquid crystal technology, applied in liquid crystal materials, diffraction gratings, chemical instruments and methods, etc., can solve problems such as reducing the diffraction efficiency of holographic polymer dispersed liquid crystal gratings, increasing system viscosity and light scattering, and reducing grating diffraction efficiency. , to reduce the anchoring force, reduce light scattering, and increase the diffraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The holographic polymer dispersed liquid crystal of the present invention is uniformly mixed by photopolymerizable monomers, photoinitiators, liquid crystals, and thermal polymerization inhibitors, and then formed in situ under the holographic illumination of coherent lasers. The high diffraction efficiency of the present invention 1. The preparation method of holographic polymer dispersed liquid crystal with low driving voltage specifically includes the following steps:

[0047] (1) Put the components of the holographic polymer dispersed liquid crystal into a dark reactor, and mix at room temperature (20-30°C) to obtain a uniform mixed solution;

[0048] (2) Pour the mixed solution obtained in step (1) into a liquid crystal cell whose inner surface is covered with a conductive coating to obtain a package with a uniform thickness;

[0049] (3) Divide a laser beam into two coherent beams of equal intensity, expand the beam to form an interference field, and place the package de...

Embodiment 1

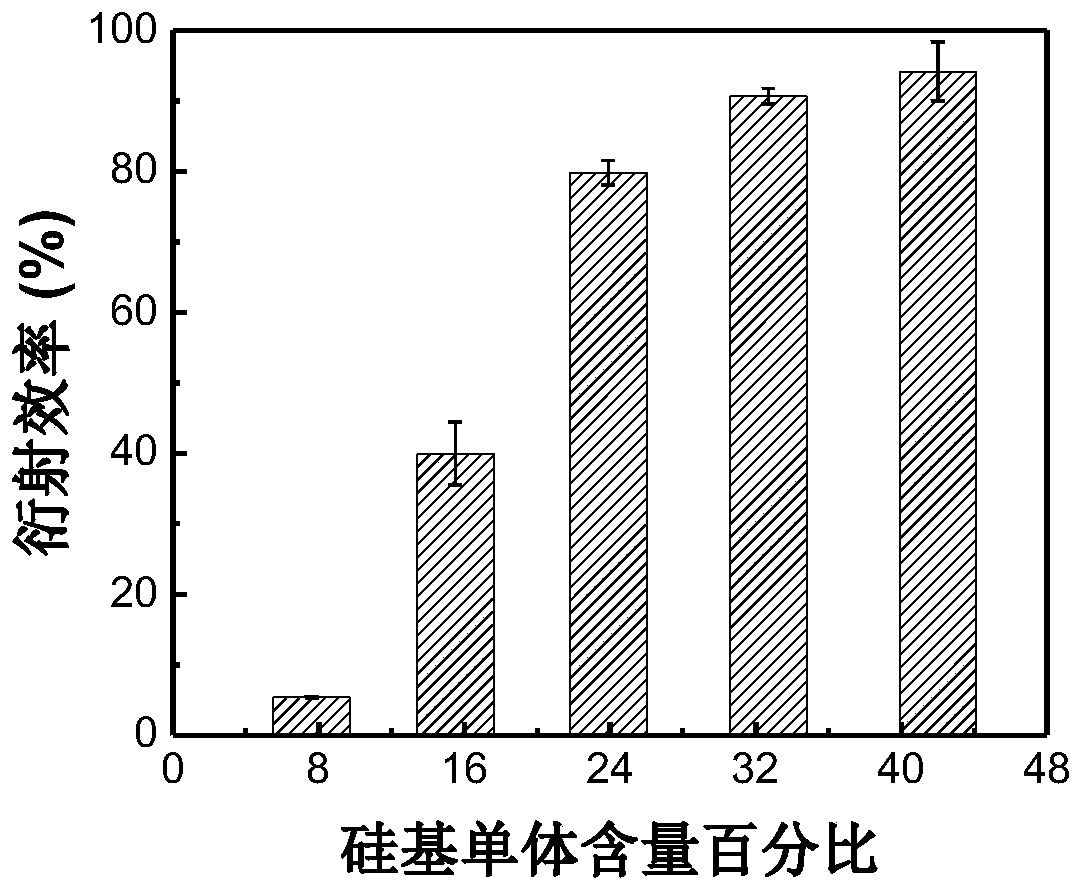

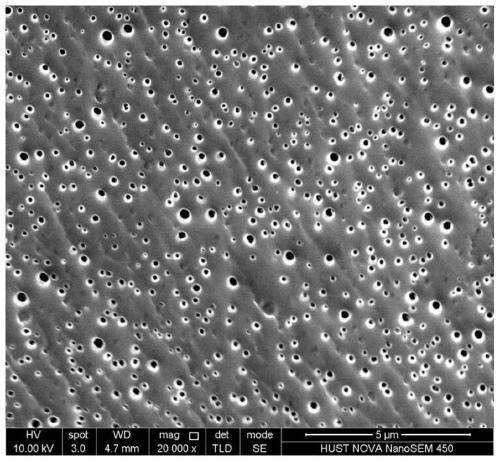

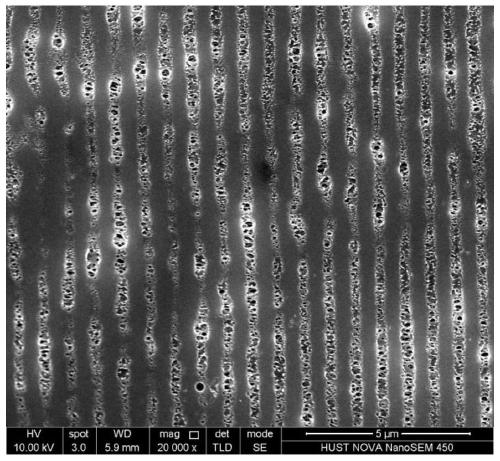

[0059] A holographic polymer dispersed liquid crystal with high diffraction efficiency and low driving voltage, including 60wt.% photopolymerizable monomer, 1.95wt.% photoinitiator, 38wt.% liquid crystal and 0.05wt.% thermal polymerization inhibitor , The diffraction efficiency is 88%, the threshold voltage and saturation voltage are 3.4 and 6.7V / μm, respectively.

[0060] The photopolymerizable monomer is Si 2 The core thiol monomer (the structure is shown in formula (1), and n=6, R 1 =R 2 =C 5 H 11 , R 3 =R 4 =C 2 H 4 SH, R 5 =R 6 =CH 3 ), trimethylolpropane tris(3-mercaptopropionate), pentaerythritol triacrylate, and pentaerythritol triallyl ether in a mixture of 3:2:2:2 in molar ratio, and the molar percentage of silicon-based monomer is 33.3%. The photoinitiator is Irgacure 184 / dibenzoyl peroxide (the mass ratio of the two is 1:10). The liquid crystal is E7, and the thermal polymerization inhibitor is p-benzoquinone.

[0061] The preparation method of the holographic polymer...

Embodiment 2

[0067] A holographic polymer dispersed liquid crystal with high diffraction efficiency and low driving voltage, including 69.3wt.% photopolymerizable monomer, 1.8wt.% photoinitiator, 30wt.% liquid crystal, and 0.1wt.% thermal polymerization resistance The diffraction efficiency is 94%, and the threshold voltage and saturation voltage are 1.4V / μm and 4.4V / μm, respectively.

[0068] The photopolymerizable monomer is SiO 1.5 The core thiol monomer (structure is shown in formula (1), and n=8, R 1 =R 2 =R 3 =R 4 =C 3 H 7 , R 5 =R 6 =R 7 =R 8 =C 3 H 6 According to the mixture of SH) and triallyl isocyanurate in a molar ratio of 3:4, the molar percentage of the silicon-based monomer is 42.9%. The photoinitiator is 3,3'-carbonyl bis(7-diethylamine coumarin) / N-phenylglycine (the mass ratio of the two is 1:2). The liquid crystal is P0616A, and the thermal polymerization inhibitor is tris(N-nitroso-N-phenylhydroxylamine) aluminum salt.

[0069] The preparation method of the holographic polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com