Low-temperature low-damage shale gas slickwater fracturing fluid and preparation method thereof

A shale gas and water fracturing technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult flowback of fracturing fluid, easy retention of polymers, and damage to reservoirs, etc., to achieve Reduce the burden of environmental protection, improve the conductivity of cracks, and have good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 400g of tap water into a stirring container, add 0.10% drainage aid FLYZ and 0.20% clay stabilizer FLYF sequentially in mass percentage. Adjust the speed of the agitator to 1000-1500rad / min, and add 0.04% drag reducer (completely added within 30s), 0.005% destroyer BRE-1 and 0.005% destroyer BRE-2 (within 30s) under stirring condition finished), and stirred for 1 min to obtain a low-temperature low-damage slippery water system.

[0024] The slippery water that obtains in embodiment 1 is carried out drag reduction rate test, obtains its drag reduction rate and the relationship curve figure of shear rate, as figure 1 Shown, wherein A is the slick water obtained in Example 1. It can be seen from the figure that as the shear rate increases, the drag reduction rate of slick water gradually increases, indicating that slick water has better drag reduction performance.

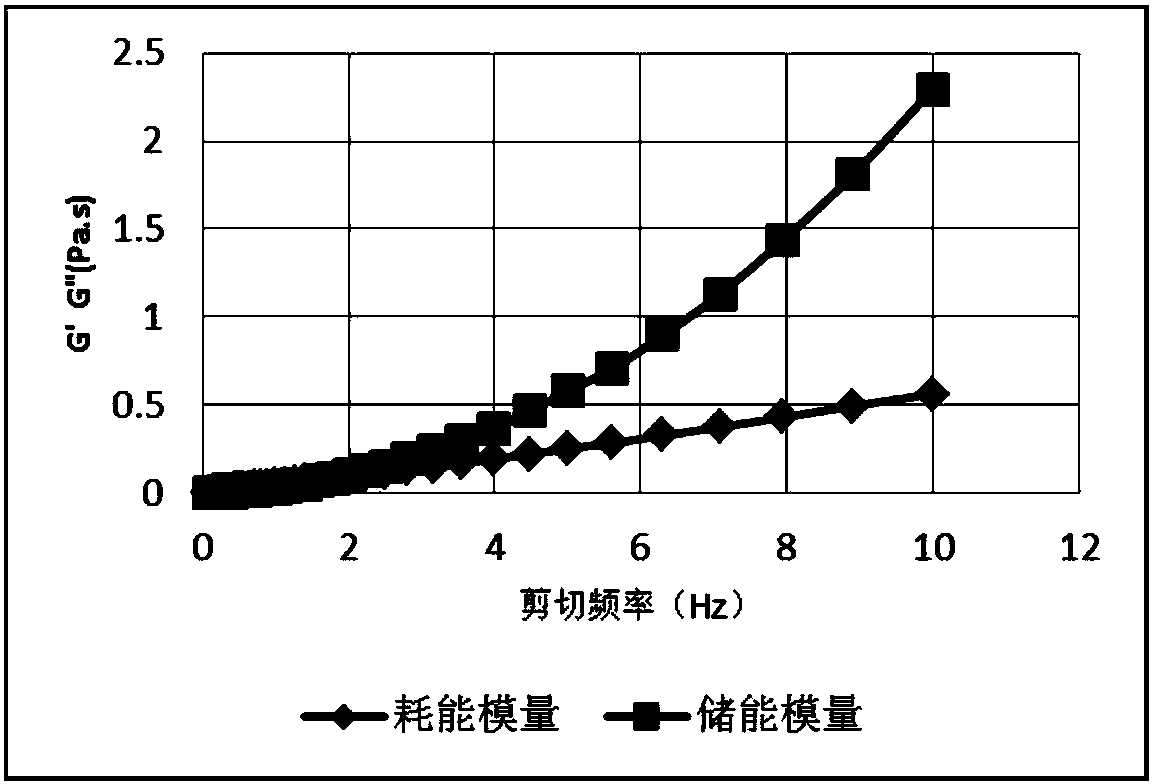

[0025] Adopt HAKKE MARS 60 high temperature and high pressure rheometer to carry out frequency scann...

Embodiment 2

[0028] Weigh 400g of tap water into a stirring container, add 0.20% of drainage aid FLYZ and 0.30% of clay stabilizer FLYF in order by mass percentage. Adjust the speed of the agitator to 1000-1500rad / min, and add 0.08% drag reducer (completely added within 30s), 0.01% destroyer BRE-1 and 0.01% destroyer BRE-2 (within 30s) under stirring finished), and stirred for 1 min to obtain a low-temperature low-damage slippery water system.

[0029] The slippery water obtained in embodiment 2 is carried out drag reduction rate test, obtains its drag reduction rate and the relationship curve figure of shear rate, as figure 1 Shown, wherein B is the slippery water that obtains in embodiment 2.

[0030] The viscosity of slippery water obtained in Example 2, surface tension, anti-swelling rate, and viscosity and molecular weight after standing at room temperature for 24 hours were tested, and the results are shown in Table 1-Table 4.

Embodiment 3

[0032] Weigh 400g of tap water into a stirring container, and add 0.15% of the drainage aid FLYZ and 0.35% of the clay stabilizer FLYF in order by mass percentage. Adjust the speed of the agitator to 1000-1500rad / min, and add 0.06% drag reducer (completely added within 30s), 0.005% destroyer BRE-1 and 0.01% destroyer BRE-2 (within 30s) under stirring condition finished), and stirred for 1 min to obtain a low-temperature low-damage slippery water system.

[0033] The slippery water that obtains in embodiment 3 is carried out drag reduction rate test, obtains its drag reduction rate and the relationship curve figure of shear rate, as figure 1 Shown, wherein C is the slippery water that obtains in embodiment 3.

[0034] The viscosity of slippery water obtained in Example 3, surface tension, anti-swelling rate, and viscosity and molecular weight after standing at room temperature for 24 hours were tested, and the results are shown in Table 1-Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com