High-temperature-resistance gas well liquid anti-salt foam scrubbing agent

A high temperature resistant, gas well technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low cost, high solubility, high temperature resistance, salt resistance, foaming and foam stabilization ability, etc., to achieve foaming With remarkable foam stabilizing ability, low cost and high solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

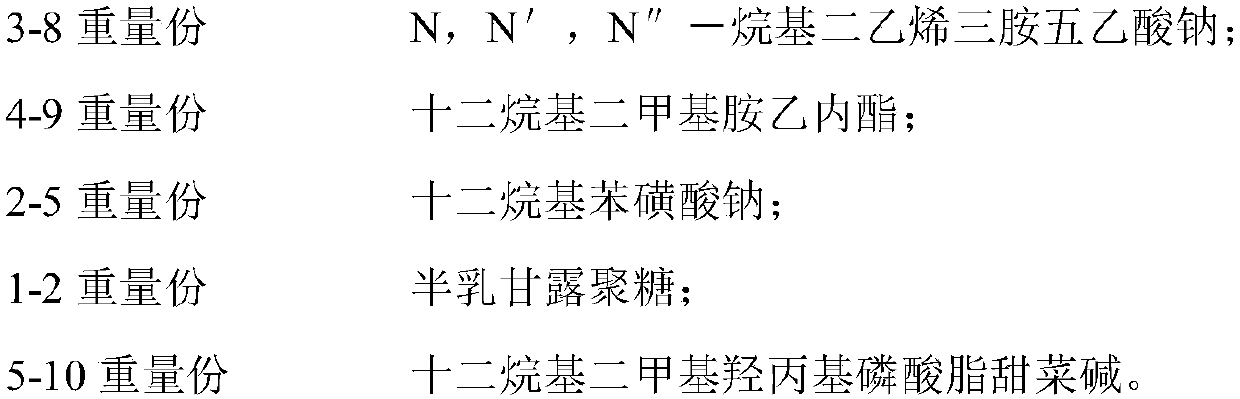

[0025] A high-temperature-resistant gas well liquid anti-salt foaming agent, consisting of the following components by weight:

[0026]

[0027] In this embodiment, the preparation process of the above-mentioned high-temperature-resistant gas well liquid anti-salt foaming agent includes: N, N', N"-alkyldiethylenetriaminepentaacetic acid sodium, dodecyldimethylamine ethyl Lactone, sodium dodecylbenzenesulfonate, galactomannan, and dodecyldimethylhydroxypropyl phospholipid betaine can be mixed evenly. The N, N', N"-alkyldiethylene Sodium triaminepentaacetate is NDDTP.

[0028] Through the above configuration, the present invention can effectively meet the requirements of low cost, high solubility, high temperature resistance, salt resistance, foaming and foam stabilizing ability, and the effect is very remarkable.

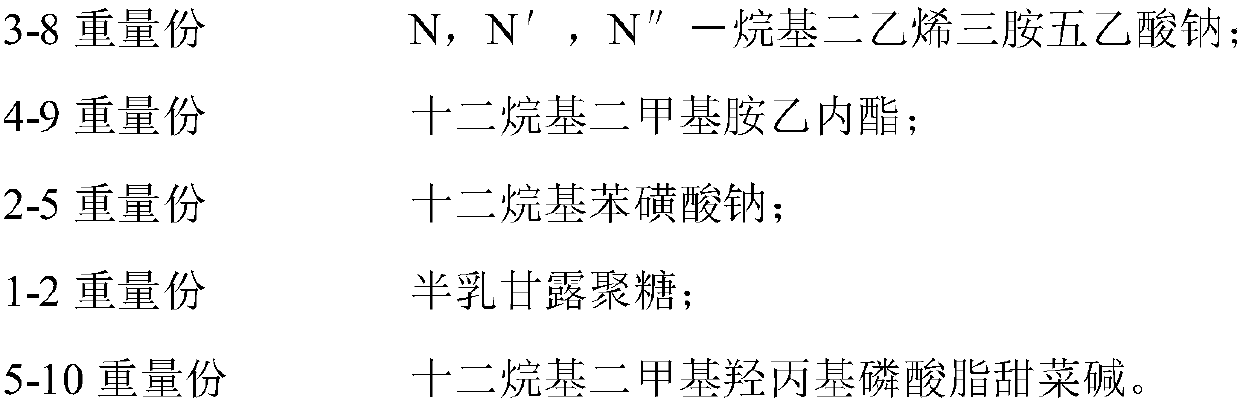

Embodiment 2

[0030] The preparation process of the anti-temperature and anti-salt foaming agent consists of the following components by weight:

[0031]

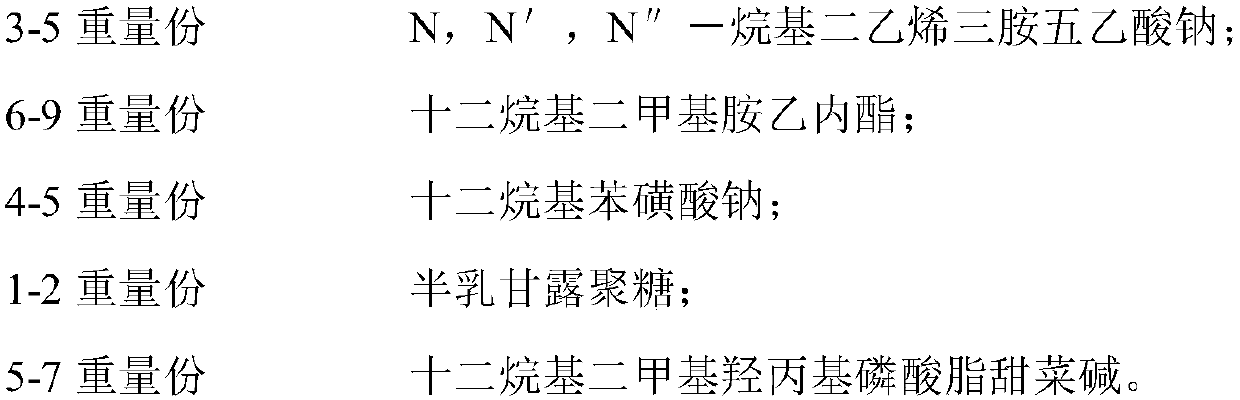

Embodiment 3

[0033] The difference between this embodiment and embodiment 1 is that it consists of the following components by weight:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com