Bisphenol-A F-PEG block copolymer hydrophilic surface coating and preparation method thereof

A technology of block copolymer and hydrophilic surface, applied in the direction of coating, etc., can solve the problems of few types of anti-icing coatings and large application limitations, and achieve prolonged freezing time, short reaction time and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of bisphenol AF polyarylate with double bonds in the terminal group:

[0039] Add 5g of bisphenol AF type diallyl ether, 0.15g of Grubbs-Hoveyda II catalyst and 10g of trifluorotoluene into the reaction flask, stir evenly, raise the temperature to 80°C, react for 2 hours, and cool down to stop the reaction. The solvent was removed by rotary evaporation to obtain a brown solid product with a number average molecular weight of 2700.

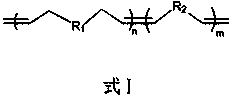

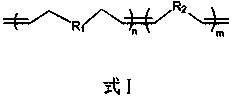

[0040] 2) Preparation of bisphenol AF-PEG block copolymers with double bonds in the main chain:

[0041] 5.4g (0.002mol) of bisphenol AF polyarylate with double bonds in the end group prepared in the above step 1), 6g (0.003mol) of polyethylene glycol diacrylate (number average molecular weight of 2000) and 0.041g (0.00005 mol) Grubbs I catalyst and 20g tetrahydrofuran, put into the reaction flask, blow nitrogen, stir evenly, raise the temperature to 60°C, react for 3h, remove the solvent, and obtain a brown product with a nu...

Embodiment 2

[0045] 1) Preparation of bisphenol AF polyarylate with double bonds in the terminal group:

[0046] Add 5g of bisphenol AF diacrylate, 0.05g of Grubbs-Hoveyda I catalyst and 20g of dimethylformamide into the reaction flask, stir evenly, raise the temperature to 90°C, react for 6h, and cool down to stop the reaction. The solvent was removed by rotary evaporation to obtain a brown solid product with a number average molecular weight of 31000.

[0047] 2) Preparation of bisphenol AF-PEG block copolymers with double bonds in the main chain:

[0048] 3.1g (0.0001mol) of bisphenol AF polyarylate with double bonds in the end group prepared in the above step 1), 4g (0.0004mol) of polyethylene glycol diacrylate (number average molecular weight of 10000) and 0.0042g (0.000005 mol) Grubbs II catalyst and 20g of dimethylformamide were added to the reaction flask, nitrogen was blown, and after stirring evenly, the temperature was raised to 80°C, reacted for 6h, and the solvent was removed...

Embodiment 3

[0052] 1) Preparation of bisphenol AF polyarylate with double bonds in the terminal group:

[0053] Add 5g of bisphenol AF type diallyl benzoxazine, 0.02g of Grubbs-Hoveyda II catalyst and 5g of pentafluorodichloropropane into the reaction flask, stir evenly, raise the temperature to 60°C, react for 2h, cool down to stop the reaction . The solvent was removed by rotary evaporation to obtain a brown solid product with a number average molecular weight of 11000.

[0054] 2) Preparation of bisphenol AF-PEG block copolymers with double bonds in the main chain:

[0055] 2.2g (0.0002mol) of bisphenol AF polyarylate with double bonds in the end group prepared in the above step 1), 0.4g (0.0004mol) of polyethylene glycol divinyl ether (number average molecular weight of 1000) and 0.044g Add (0.00005mol) GrubbsIII catalyst and 10g tetrahydrofuran into the reaction flask, blow nitrogen gas, stir evenly, raise the temperature to 60°C, react for 3 hours, remove the solvent, and obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com