Modified calcium carbonate used for cable rubber sheath

A rubber sheath and calcium carbonate technology, which is applied in the field of modified calcium carbonate for cable rubber sheaths, can solve problems such as poor dispersion and poor rubber compatibility, and achieve easy production, improved elongation at break, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

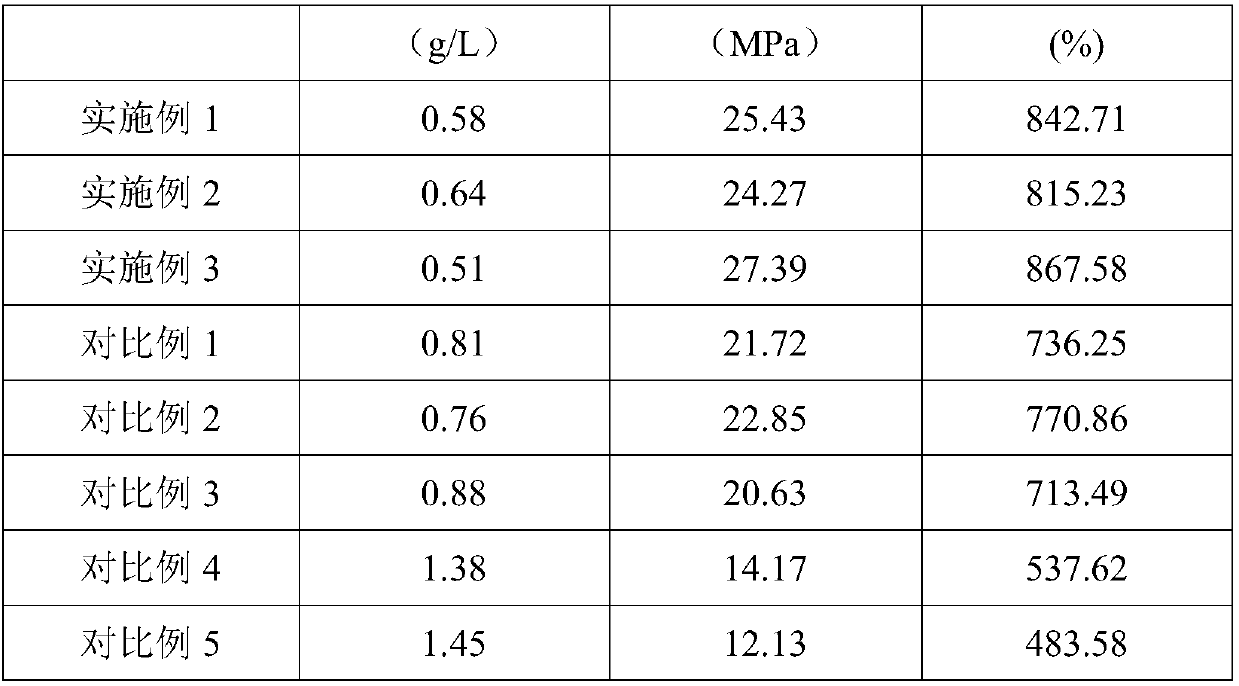

Embodiment 1

[0024] A modified calcium carbonate used for cable rubber sheath, the modified calcium carbonate is in parts by weight, including the following raw materials: 124 parts of calcium carbonate stone, 4 parts of higher fatty alcohol, 8 parts of triisopropylamine, carbon black 13 parts, 9 parts of sodium polystyrene sulfonate, 1.2 parts of sodium methacrylate sulfonate, 1.4 parts of vinyl tris (2-methoxyethoxy) silane, 0.7 parts of trimethylbutylperoxysilane, methyl 0.9 parts of glycidyl acrylate, 1.3 parts of n-butyl methacrylate, 2.1 parts of allyl methacrylate crosslinked polymer, 0.5 parts of hexamethylenetetramine, 4 parts of magnesium oxide, 0.8 parts of titanium dioxide, calcium 1.2 parts of soap stabilizer.

[0025] Titanium dioxide was modified by eicosyl laurate at pH 5.3 and temperature 30°C.

[0026] The present invention also provides a kind of modified calcium carbonate preparation method that is used for cable rubber sheath, comprises the following steps:

[0027] ...

Embodiment 2

[0033] A modified calcium carbonate used for cable rubber sheath, the modified calcium carbonate is in parts by weight, including the following raw materials: 112 parts of calcium carbonate stone, 2 parts of higher fatty alcohol, 6 parts of triisopropylamine, carbon black 8 parts, 6 parts of sodium polystyrene sulfonate, 0.9 parts of sodium methacrylate sulfonate, 1.1 parts of vinyl tris(2-methoxyethoxy) silane, 0.3 parts of trimethylbutylperoxysilane, 0.5 parts of glycidyl acrylate, 1.1 parts of n-butyl methacrylate, 1.5 parts of allyl methacrylate crosslinked polymer, 0.3 parts of hexamethylenetetramine, 3 parts of magnesium oxide, 0.5 parts of titanium dioxide, zinc 0.3 part of soap stabilizer.

[0034] Titanium dioxide is modified by modifiers of eicosyl laurate, behenyl laurate, and oleyl laurate at pH 5.9 and temperature 37°C.

[0035] The present invention also provides a kind of modified calcium carbonate preparation method that is used for cable rubber sheath, compri...

Embodiment 3

[0042]A modified calcium carbonate used for cable rubber sheath, the modified calcium carbonate is in parts by weight, including the following raw materials: 130 parts of calcium carbonate stone, 5 parts of higher fatty alcohol, 10 parts of triisopropylamine, carbon black 15 parts, 13 parts of sodium polystyrene sulfonate, 1.5 parts of sodium methacrylate sulfonate, 1.7 parts of vinyl tris (2-methoxyethoxy) silane, 0.8 parts of trimethylbutylperoxysilane, methyl 1.2 parts of glycidyl acrylate, 1.5 parts of n-butyl methacrylate, 2.3 parts of allyl methacrylate crosslinked polymer, 0.8 parts of hexamethylenetetramine, 5 parts of magnesium oxide, 1.2 parts of titanium dioxide, calcium 0.5 parts of soap stabilizer, 0.9 parts of zinc soap stabilizer.

[0043] Titanium dioxide is modified by behenyl laurate and oleyl laurate at pH 6.5 and temperature 48°C.

[0044] The present invention also provides a kind of modified calcium carbonate preparation method that is used for cable rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com