Betaine surfactant and its synthesis method and application

A technology of surfactant and synthesis method, applied in the directions of ampholyte/electroneutral surface active compound, application, chemical instrument and method, etc., can solve the problem of high production cost of sulfobetaine, difficult removal of sodium chloride, Affect the purity of the reaction product and other problems, and achieve the effect of significant sterilization effect, good compatibility, rich and delicate foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

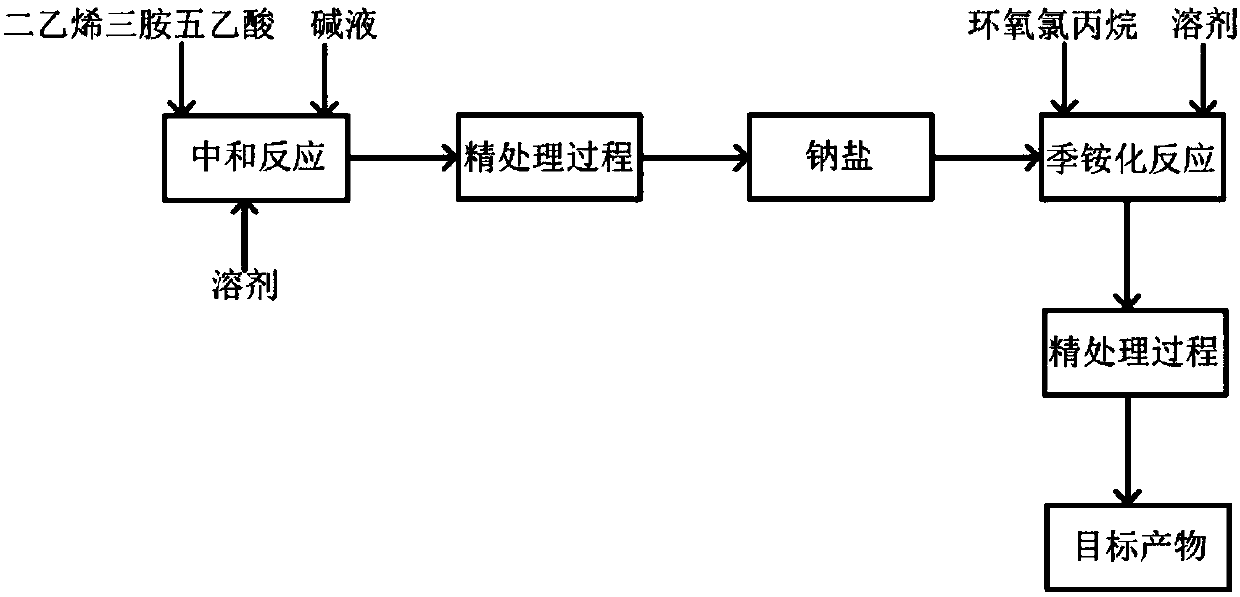

Method used

Image

Examples

Embodiment 1

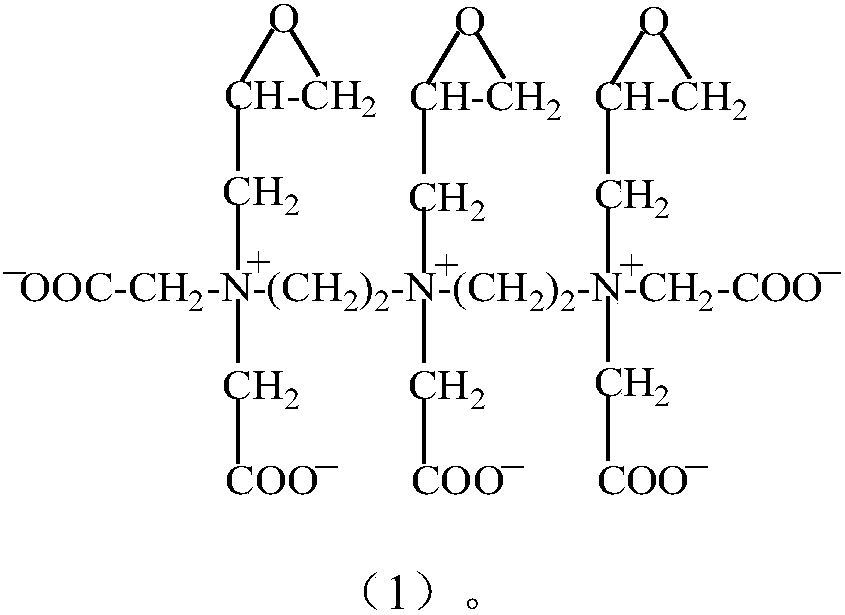

[0032] 1. Add 11.8g of diethylenetriaminepentaacetic acid, 6g of sodium hydroxide aqueous solution and 30ml of ethanol into the reaction kettle for neutralization reaction, stir and heat up to 70°C, after 3 hours of reaction, stop the reaction to obtain a colorless and transparent Solution A.

[0033] 2. The above solution A was rotated to remove the solvent, recrystallized with acetone and ethanol, filtered, and dried at 25°C for 24 hours to obtain the product diethylenetriaminepentaacetic acid pentasodium salt with a yield of 83.1%.

[0034] 3. Add 6.3g of diethylenetriaminepentaacetic acid pentasodium salt, 4.2g of epichlorohydrin and 30ml of isopropanol into the reaction kettle to carry out quaternization reaction, maintain the pH of the system=9~10, stir and heat up to After 18 hours of reaction at 60°C, the reaction was stopped to obtain a transparent solution B.

[0035] 4. The above-mentioned solution B is subjected to rotary evaporation, solvent and unreacted epichlo...

Embodiment 2

[0037] 1. Add 11.8g of diethylenetriaminepentaacetic acid, 8g of sodium carbonate aqueous solution and 40ml of isopropanol into the reaction kettle for neutralization reaction. Stir and heat up to 80°C. After 2 hours of reaction, stop the reaction to obtain colorless Clear solution A.

[0038] 2. The above solution A was rotated to remove the solvent, recrystallized with acetone and ethanol, filtered, and dried at 60°C for 14 hours to obtain the product diethylenetriaminepentaacetic acid pentasodium salt with a yield of 81.5%.

[0039] 3. Add 6.3g of diethylenetriaminepentaacetic acid pentasodium salt, 4.2g of epichlorohydrin and 35ml of n-butanol into the reaction kettle to carry out quaternization reaction, maintain the pH of the system=9~10, stir and heat up to After 14 hours of reaction at 80°C, the reaction was stopped to obtain a transparent solution B.

[0040] 4. The above-mentioned solution B is subjected to rotary evaporation, solvent and unreacted epichlorohydrin a...

Embodiment 3

[0042] 1. Add 11.8g of diethylenetriaminepentaacetic acid, 12.6g of aqueous solution prepared by sodium bicarbonate and 50ml of n-butanol into the reaction kettle for neutralization reaction, stir and raise the temperature to 90°C, and stop the reaction after 0.5h of reaction. A colorless and transparent solution A was obtained.

[0043] 2. The above solution A was rotary evaporated to remove the solvent, recrystallized with acetone and ethanol, filtered, and dried at 80°C for 8 hours to obtain the product diethylenetriaminepentaacetic acid pentasodium salt with a yield of 83.4%.

[0044] 3. Add 6.3g of diethylenetriaminepentaacetic acid pentasodium salt, 4.2g of epichlorohydrin and 25ml of n-amyl alcohol into the reaction kettle to carry out quaternization reaction, maintain the pH of the system=9~10, stir and heat up to After reacting for 10 hours at 90°C, stop the reaction to obtain a transparent solution B.

[0045] 4. The above-mentioned solution B is subjected to rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com