Rapid curing fermentation cabin for edible mushroom culture material

A technology of compost and edible fungus, which is applied in application, organic fertilizer, preparation of organic fertilizer, etc. It can solve the problems of increasing production cost, slow fermentation, and no air circulation during accumulation and fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

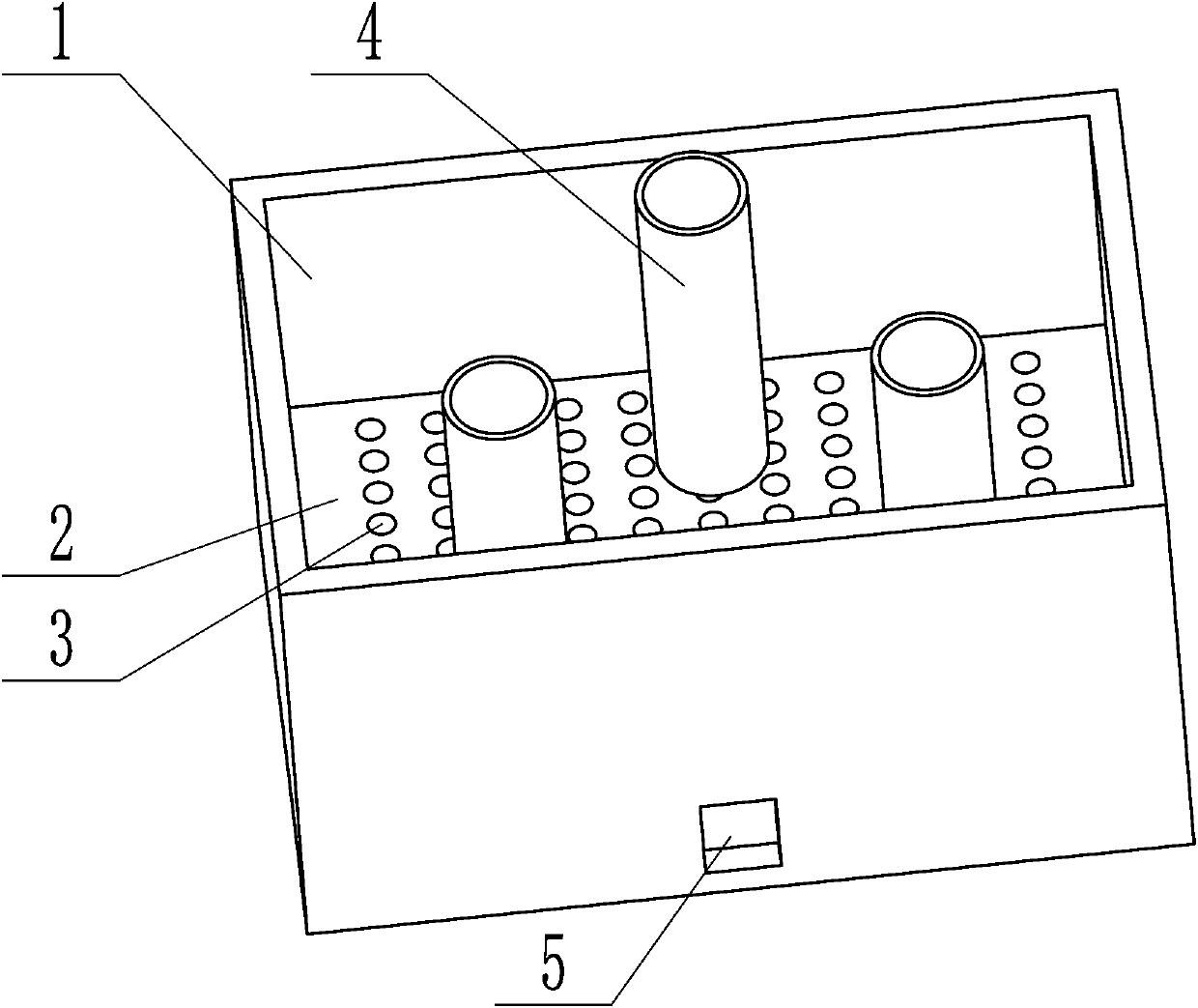

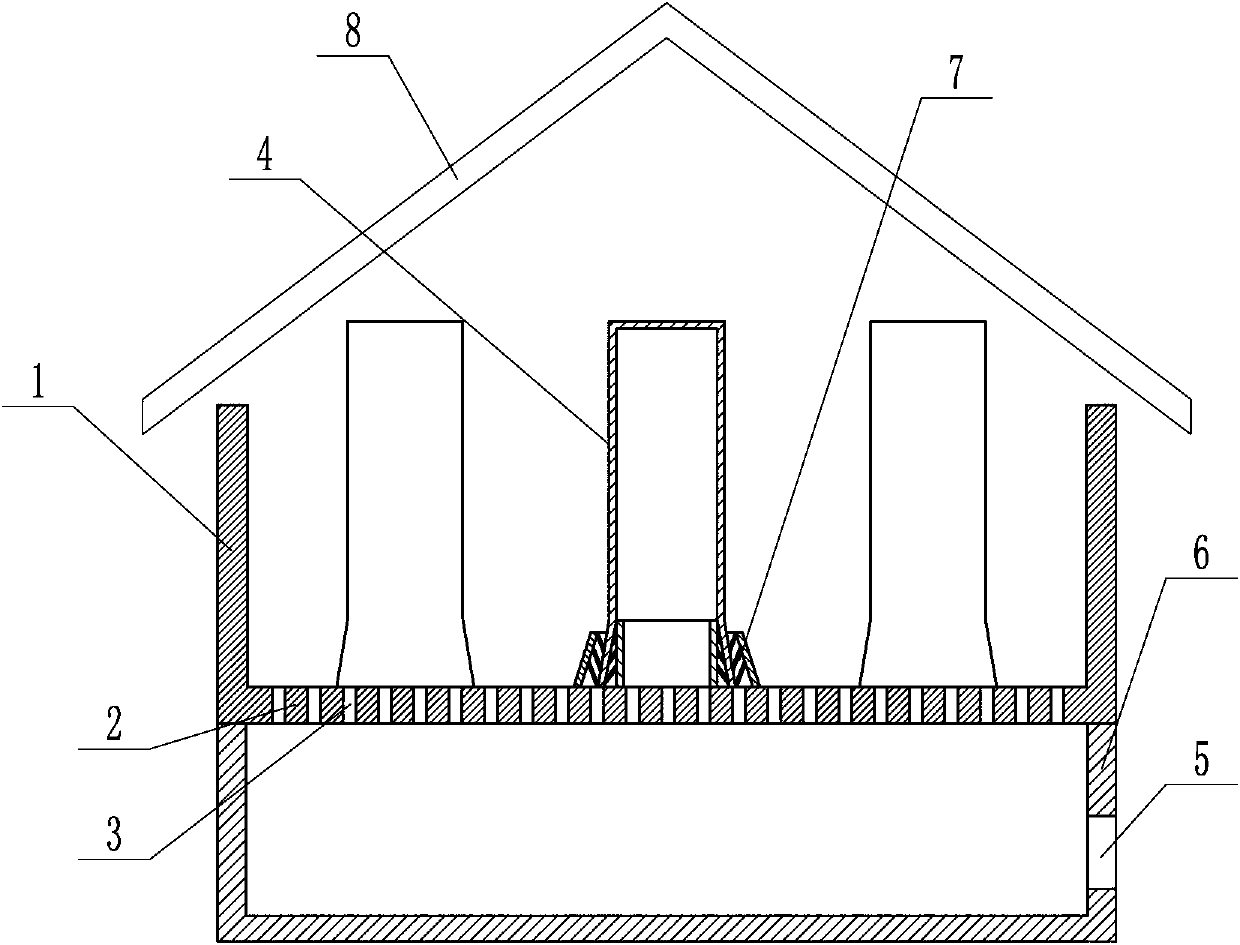

[0018] as attached figure 1 , 2 , 4, the present invention includes a side plate 1, a base plate 2 arranged at the bottom of the side plate 1, an exhaust tube 4 arranged on the upper surface of the base plate 2, and a through hole 3 evenly arranged on the base plate 2; the side plate 1 Enclosed with the bottom plate 2 to form a warehouse structure, a support plate 6 is provided under the bottom plate 2;

[0019] The exhaust tube 4 is arranged on the bottom plate 2 in the shape of a character, and the exhaust tube 4 includes a cylindrical upper cylinder 401 and a trumpet-shaped lower cylinder 402 arranged on the lower part of the upper cylinder 401. The lower part of the cylinder 402 is in contact with the bottom plate 2 .

[0020] The height of the bottom plate 2 is 15-25cm, the aperture of the through hole 3 is 1-2mm, the height of the exhaust cylinder 4 is 1.2-1.8m, the diameter of the upper cylinder 401 is 5-20cm, two adjacent The distance between the exhaust tubes 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com