Environmentally-friendly and fadeless red decorative finish mortar

A technology of veneer mortar and red, applied in the field of red veneer mortar, can solve the problems of prone to color difference, uneven pigment dispersion, efflorescence, etc., and achieve the effect of improving efflorescence performance, promoting hydration reaction, and improving compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

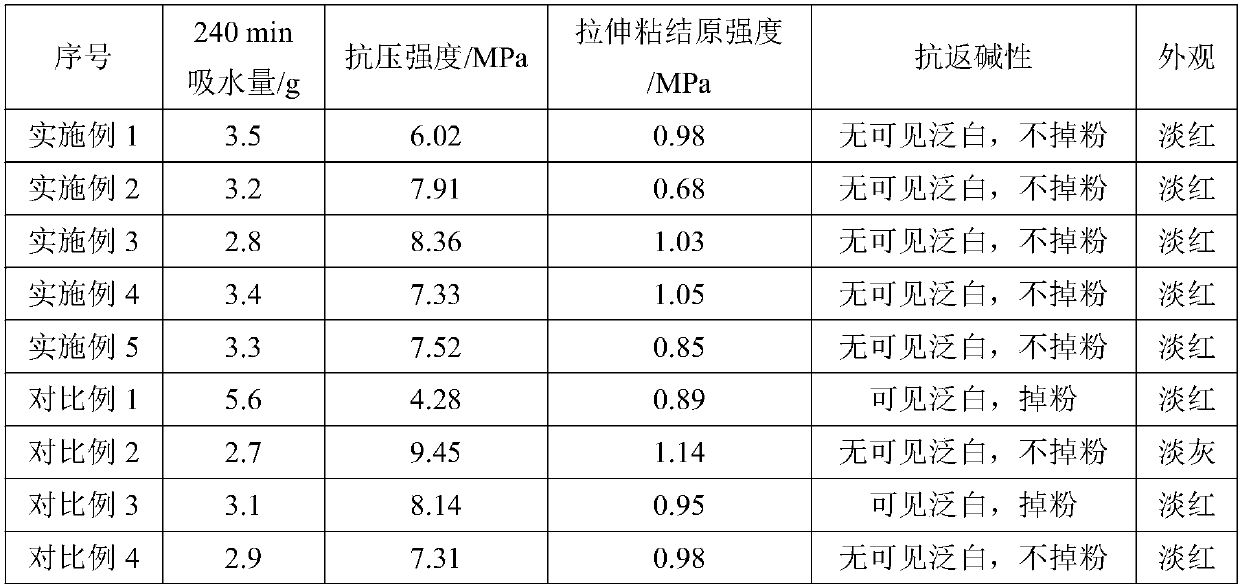

Examples

Embodiment 1

[0026] An environmentally friendly, non-fading red facing mortar, consisting of the following parts by weight of raw materials: 40 parts of white Portland cement, 3 parts of phosphoaluminate cement, 20 parts of calcined coal gangue powder, 8 parts of redispersible latex powder , 1 part of nano silica, 2 parts of rheological thickener, 0.5 part of water reducing agent, 1.5 part of water repellent, 0.2 part of reinforcing agent, 1 part of wetting and dispersing agent, 0.01 part of defoaming agent, 0.5 part of phytic acid , 80 parts of washed river sand.

[0027] The redispersible latex powder is ethylene-vinyl acetate copolymer latex powder.

[0028] The average particle size of the nano silica is 15 nm, and the SiO2 content is 99.5%.

[0029] The rheological thickener consists of hydroxypropyl starch ether and γ-aminopropyl triethoxysilane.

[0030] The water reducing agent is a naphthalene water reducing agent.

[0031] The water repellent is composed of aluminum chloride and zinc ste...

Embodiment 2

[0036] An environmentally friendly, non-fading red facing mortar, consisting of the following parts by weight of raw materials: 50 parts by weight of white Portland cement, 1 part of phosphoaluminate cement, 30 parts of calcined coal gangue powder, 3 parts of redispersible latex powder , 5 parts of nano silica, 0.1 part of rheological thickener, 1 part of water reducing agent, 0.5 part of water repellent, 0.8 part of reinforcing agent, 0.1 part of wetting and dispersing agent, 0.05 part of defoaming agent, 0.1 part of phytic acid , 100 parts of washed river sand.

[0037] The white Portland cement is white Portland cement that meets the 42.5 grade requirements in GB / T 2015-2005 "White Portland Cement".

[0038] The phosphoaluminate cement is a system cementing material described in Chinese Patent CN1498870, with an alkali content of 80MPa.

[0039] The calcined coal gangue powder is calcined from coal gangue at 700-900℃ for 1-2h and then ground to specific surface area ≥450m 2 / kg, ...

Embodiment 3

[0050] An environmentally friendly, non-fading red facing mortar, composed of the following parts by weight of raw materials: 45 parts of white Portland cement, 2 parts of phosphoaluminate cement, 25 parts of calcined coal gangue powder, and 5 parts of redispersible latex powder , 4 parts of nano silica, 1 part of rheological thickener, 0.8 part of water reducing agent, 1.2 part of water repellent, 0.6 part of reinforcing agent, 0.9 part of wetting and dispersing agent, 0.04 part of defoaming agent, 0.4 part of phytic acid , 90 parts of washed river sand.

[0051] The alkali content of the phosphoaluminate cement is 0.35%, the 12h compressive strength is 48.1MPa, and the 28d compressive strength is 90.30MPa.

[0052] The calcined coal gangue powder is calcined at 700°C for 2 hours and then ground to a specific surface area of ≥450m 2 / kg, the ignition loss is 3%, the 7d activity is 82%, and the 28d activity is 93%.

[0053] The redispersible latex powder is ethylene-vinyl acetate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com