A method for efficiently treating deltamethrin wastewater

A deltamethrin and wastewater technology, which is applied in the field of efficient treatment of deltamethrin wastewater, can solve the problems of high cost of chemical treatment, secondary pollution of the environment, and the stability of the repeated use of adsorbents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

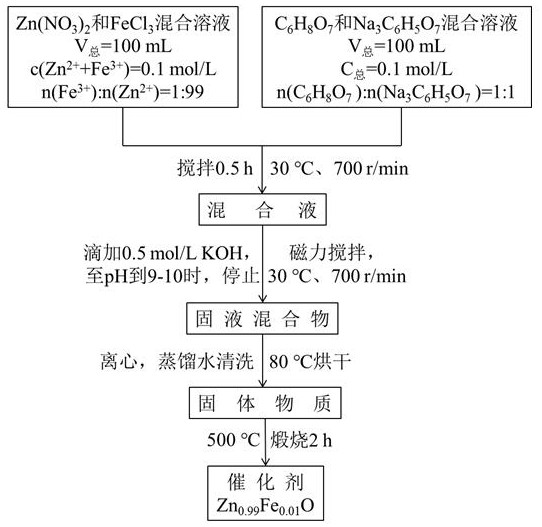

Method used

Image

Examples

Embodiment 1

[0032] The influence of embodiment 1 deltamethrin initial concentration

[0033] The deltamethrin solutions with initial concentrations of 50, 100, 200, and 300 mg / L were treated with 125W high-pressure fluorescent mercury lamps, and the effects of initial concentrations on the removal rate of deltamethrin were investigated. Experimental conditions: reaction time 240 min, Zn 0.99 f 0.01 The concentration of the O catalyst was 0.5 g / L, the temperature was 30 °C, and the pH was neutral. After the reaction, the reaction solution was taken out, centrifuged at a speed of 6000r / min for 20 min, and the concentration of deltamethrin in the supernatant was determined. When the initial concentration was 50 and 100 mg / L, the removal effect of deltamethrin was better, and the removal rates were 61.4% and 56.2%, respectively.

Embodiment 2

[0034] Example 2 Zn 0.99 Fe 0.01 The influence of O dosage

[0035] A 125 W high-pressure fluorescent mercury lamp was used to treat deltamethrin solution with a concentration of 100 mg / L, and the effect of catalyst dosage on the removal rate of deltamethrin was investigated, and Zn 0.99 Fe 0.01 The concentration of O is 0.0, 0.1, 0.5, 1.0, 2.0 g / L respectively, and other experimental conditions are the same as above (suspension treatment method and measurement method are the same as in Example 1, the same below), and the concentration of deltamethrin in the supernatant is measured . When Zn 0.99 Fe 0.01 The mass concentration of O was 1.0 g / L, and the removal rate reached the highest, which was 69.6%.

Embodiment 3

[0036] The influence of embodiment 3 temperature

[0037] A 125W high-pressure fluorescent mercury lamp was used as a light source to treat deltamethrin solution with a concentration of 100 mg / L, and the effect of reaction temperature on the removal rate of deltamethrin in wastewater was investigated. The photocatalytic degradation temperatures were set at 20, 30, 40 , 50°C. Other experimental conditions: reaction time 240 min, Zn 0.99 Fe 0.01 The concentration of the O catalyst was 1.0 g / L, the temperature was 30 °C, and the pH was neutral. Considering the removal rate and energy consumption comprehensively, 30°C was selected as the optimal reaction temperature in this experiment, and the removal rate was 70.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com