Water-based ink drying device for polyethylene plastic film printing pattern

A technology of plastic film and printing patterns, which is applied to general parts of printing machinery, printing, printing machines, etc., can solve the problems of not meeting the requirements of use, low drying efficiency, uneven drying, etc., and achieves simple and convenient use and operation. , Increase the drying effect, the drying effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

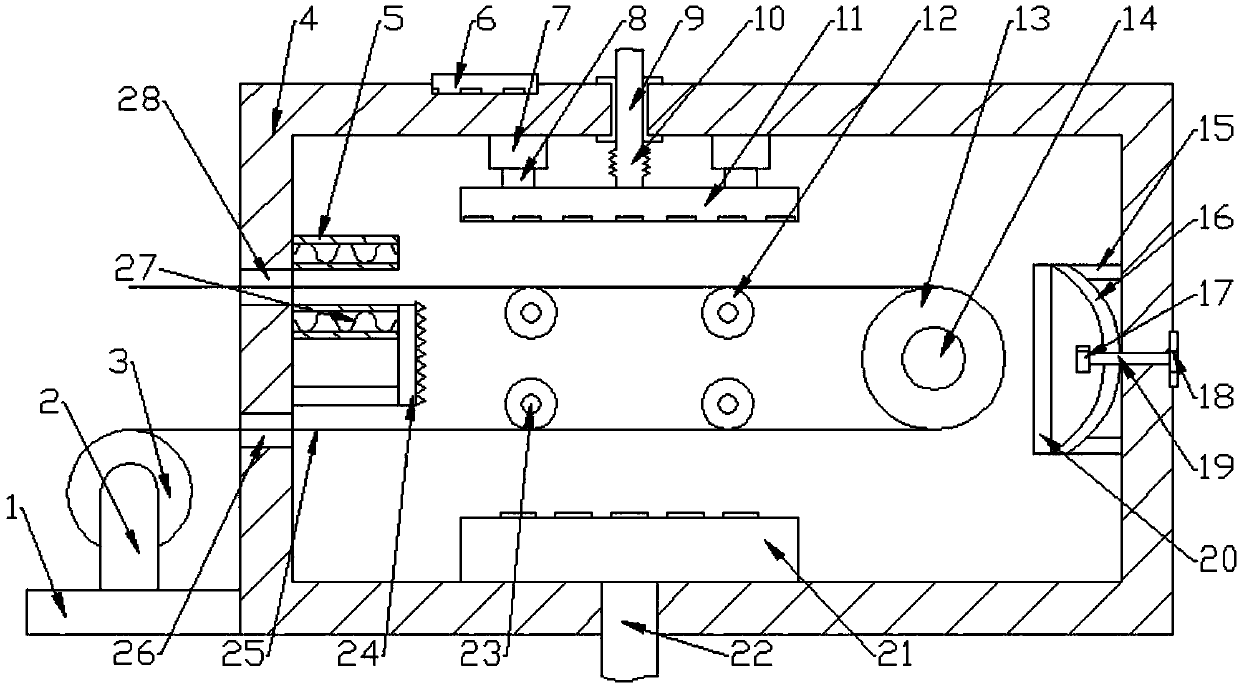

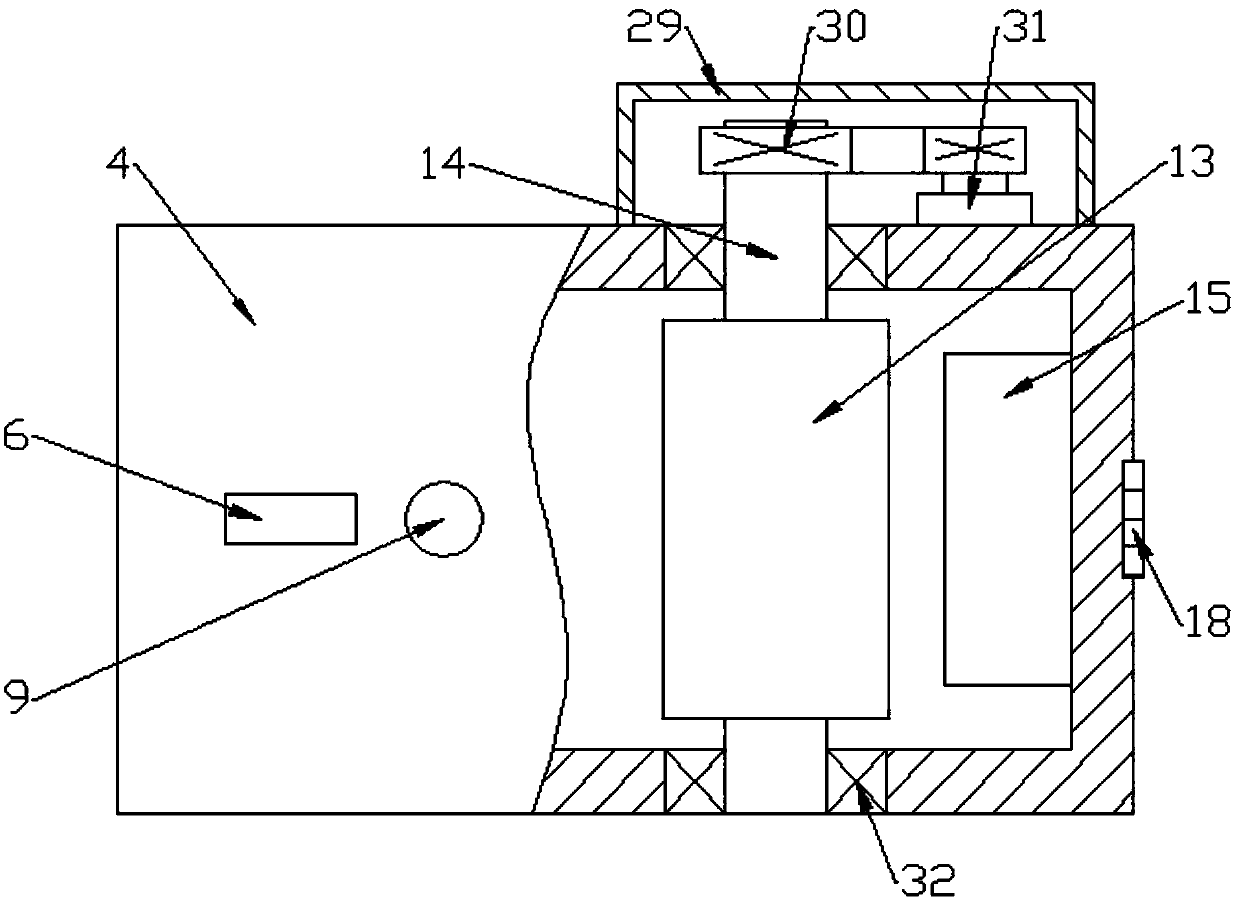

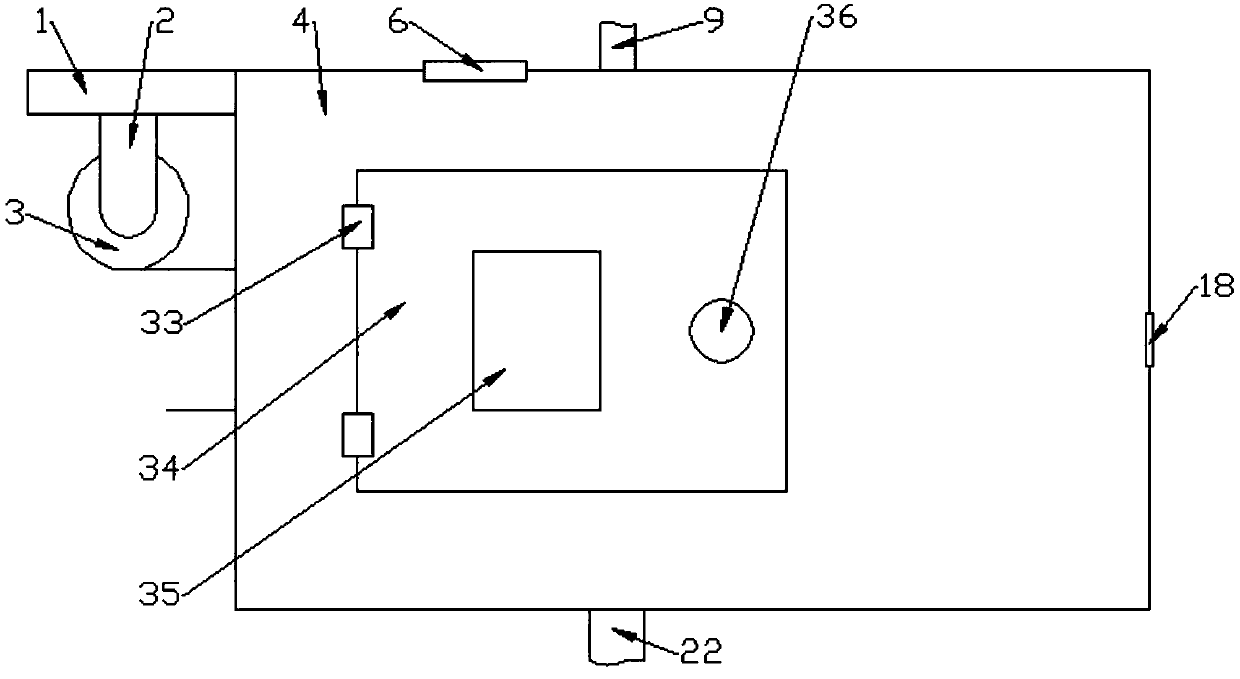

[0021] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

[0022] see Figure 1-4 , a water-based ink drying device for polyethylene plastic film printing patterns, comprising a drying box 4; a support plate 1 is welded and fixed on the lower left side of the drying box 4; the upper surface of the support plate 1 is welded and fixedly connected frame 2; a film drum 3 is installed on the connecting frame 2; a film body 25 is wound on the film drum 3; the film body 25 is connected to the drying box 4 through the outlet 26 to the right, After completion, it is wound on the film drum 3; the outlet 26 is opened in the left lower wall of the drying box 4, and an inlet 28 is arranged above it; the right side of the inlet 28 is symmetrically provided with a preheating plate 5; The preheating plate 5 is welded and fixed on the left inner wall of the drying box 4 horizontally, and the heating wire 27 is inla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com