A kind of lithium-ion battery soft coating inner layer material and preparation method thereof

A lithium-ion battery, soft coating technology, applied in secondary batteries, battery pack parts, chemical instruments and methods, etc., can solve the problem of low puncture resistance, poor adhesion of aluminum foil, high temperature heat sealing of polypropylene film Insufficient strength and other problems to achieve the effect of solving insufficient toughness, enhancing puncture resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

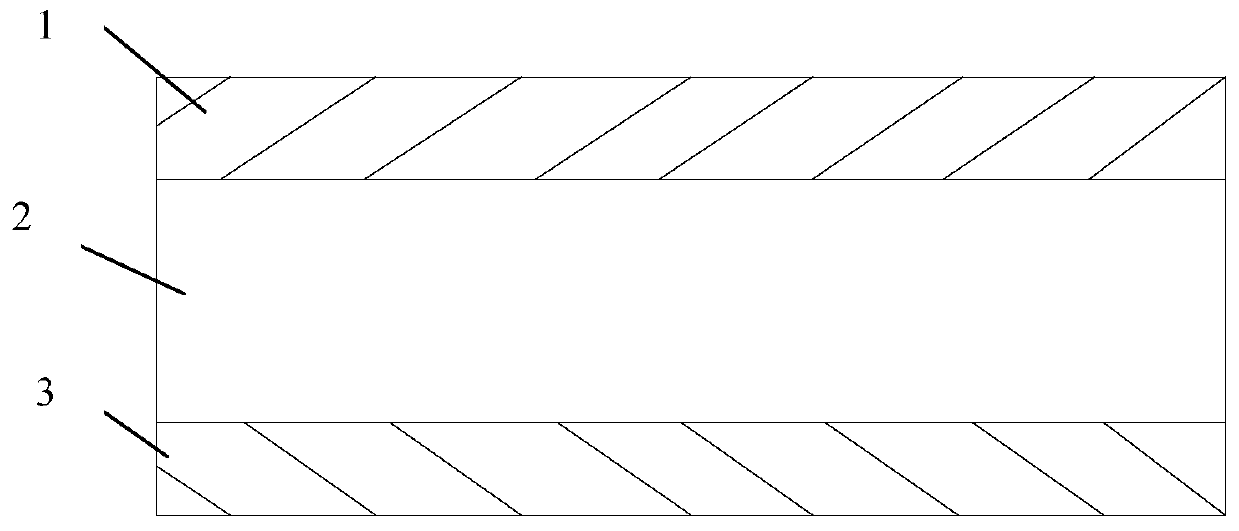

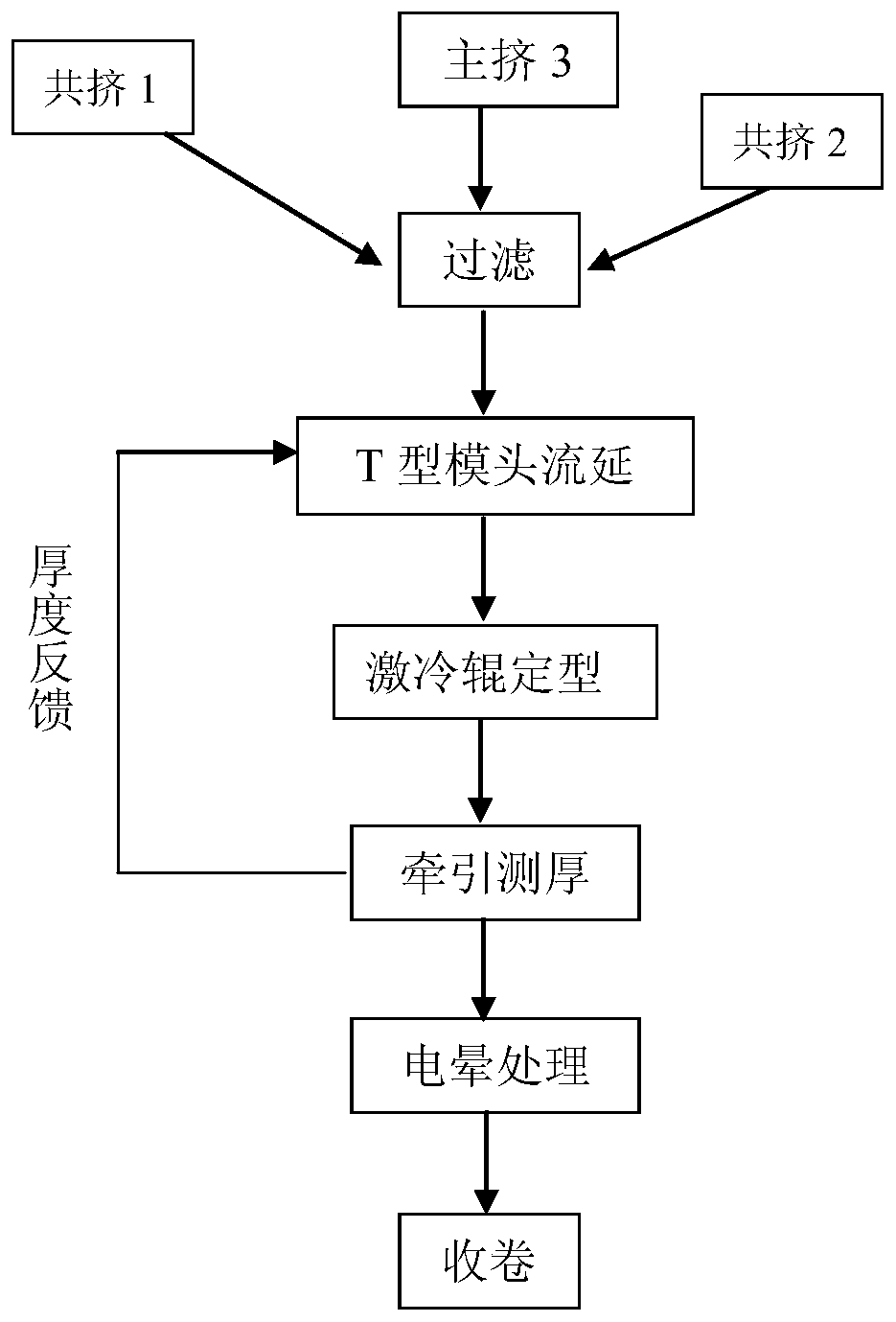

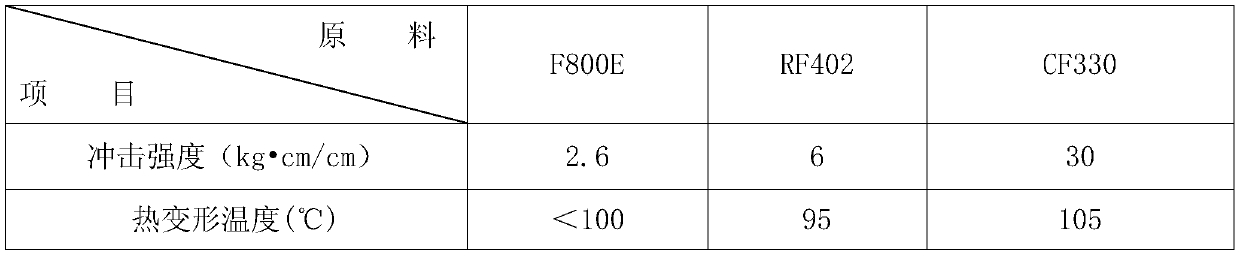

[0031] A method for preparing the inner layer material of a lithium-ion battery soft coating, the inner layer material is cast polypropylene film, adopting a three-layer structure, from top to bottom are respectively a heat-sealing layer 1, a core layer 2 and a corona layer 3. The heat-sealing layer includes binary copolymerized polypropylene, anti-adhesive agent and slippery agent, and the mass-number ratio of the binary copolymerized polypropylene, anti-adhesive agent and slippery agent is 100:1-3:0.3 -1.5; the core layer includes binary copolymerized polypropylene and slippery agent, and the mass and number ratio of the binary copolymerized polypropylene and slippery agent is: 100: (1-3); the corona layer includes The mixture of binary copolymerized polypropylene, ternary copolymerized polypropylene, carboxyl-terminated polybutadiene liquid rubber and anti-adhesive agent, the mass and number ratio of said binary copolymerized polypropylene, ternary copolymerized polypropylen...

example 1

[0044] Example 1: a kind of lithium-ion battery soft envelope inner layer material, described inner layer material is film casting polypropylene film 1#, wherein,

[0045] The heat-sealing layer adopts 100 parts of binary copolymerized polypropylene CF330, 1 part of anti-adhesive agent, and 0.35 parts of slippery agent.

[0046] The core layer adopts 100 parts of binary copolymerized polypropylene F800E and 1 part of slip agent.

[0047] The corona layer adopts 100 parts of binary copolymerized polypropylene (RF401), 5 parts of ternary copolymerized polypropylene (FL7540), 1 part of anti-sticking agent (AB6018CPP of Constamp); the carboxyl-terminated polybutadiene liquid rubber The mixing method of the mixture is an impregnation method, and the impregnation ratio concentration with the ternary copolymerized polypropylene is 0.01%.

[0048] This embodiment adopts a three-layer co-extrusion production process, and the process parameters are: corona: 25kw, casting roll temperatu...

example 2

[0049] Example 2: a kind of lithium-ion battery soft envelope inner layer material, described inner layer material is casting polypropylene film 2#, wherein,

[0050] The heat-sealing layer adopts 100 parts of binary copolymerized polypropylene (RF402), 2 parts of anti-adhesive agent, and 1 part of slippery agent.

[0051] The core layer adopts 100 parts of binary copolymerized polypropylene (RF402) and 2 parts of slippery agent.

[0052] The corona layer adopts 100 parts of binary copolymerized polypropylene (RF401), 10 parts of ternary copolymerized polypropylene (FL7540), 2 parts of anti-sticking agent (AB6018CPP of Constamp); the carboxyl-terminated polybutadiene liquid rubber The mixing method of the mixture is an impregnation method, and the impregnation ratio concentration with the ternary copolymerized polypropylene is 0.1%.

[0053] This embodiment adopts a three-layer co-extrusion production process, and the process parameters are: corona: 25kw, casting roll tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com