Preparation method of aluminum matrix composite material brake disc

A technology of aluminum-based composite materials and brake discs, applied in the direction of brake discs, etc., can solve the problems of difficult popularization and application of ordinary motorcycles, affect the mechanical properties of brake discs, and high cost, achieve good thermal conductivity and improve reliability and the effect of improving the service life and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Prepare a brake disc blank with a size of Φ300mm (outer diameter) × 200mm (inner hole) × 5mm (thickness)

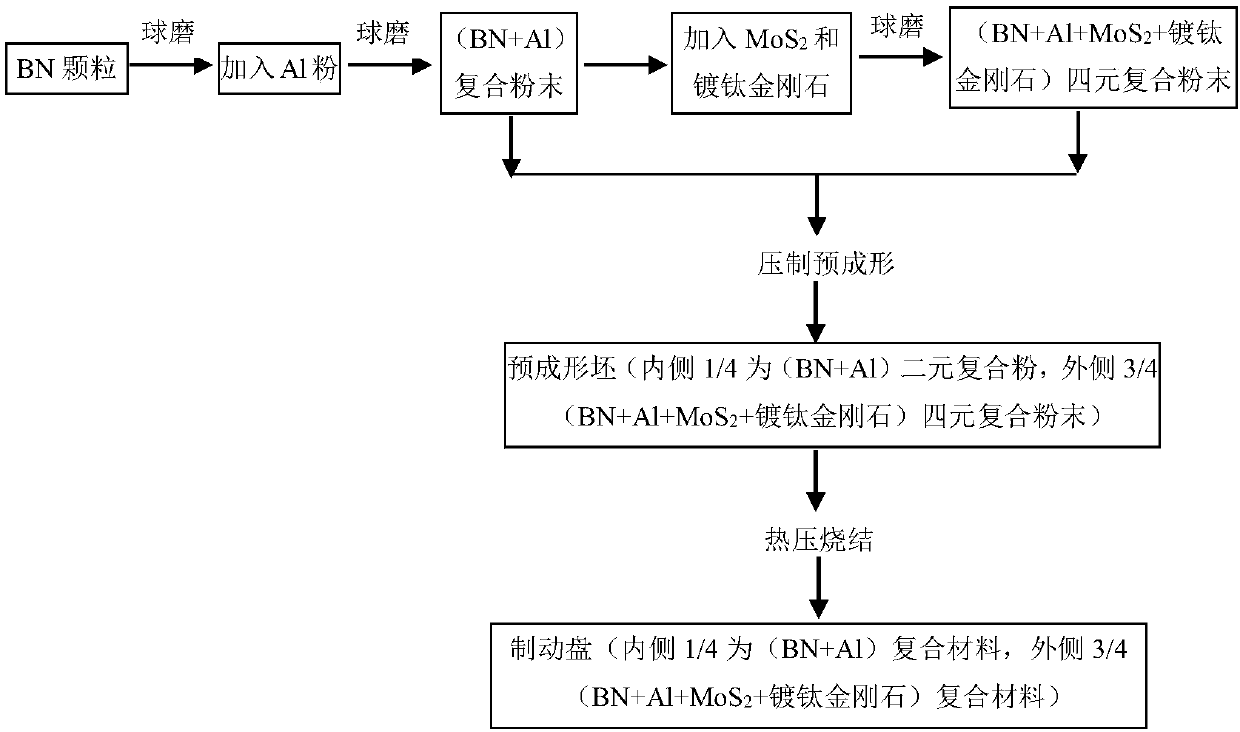

[0018] First, 15g of BN powder with a particle size of less than 50 microns is selected and placed in a ball mill for ball milling and crushing. The ball milling speed is 300 rpm, the weight ratio of ball to material is 10:1, and the ball milling time is 30 minutes. Then, the spherical powder with an average particle size of 74 microns Put 360g of aluminum powder in the ball mill to continue ball milling, and add 3600g of balls at the same time. After adding aluminum powder, the ball milling speed is 320 rpm, and the ball milling time is 1 hour. After the ball milling, take out 110g of mixed powder from the ball mill tank to fill the brake disc. The raw material of the inner 1 / 4 part, and then continue to add 135gMoS to the ball mill tank 2 and 97g titanium-coated diamond powder, MoS 2 The particle size of the powder is controlled at 5-10 microns, and the particle...

Embodiment 2

[0020] Prepare a brake disc blank with a size of Φ300mm (outer diameter) × 200mm (inner hole) × 5mm (thickness)

[0021] First, 15g of BN powder with a particle size of less than 50 microns is selected and placed in a ball mill for ball milling and crushing. The ball milling speed is 300 rpm, the weight ratio of ball to material is 10:1, and the ball milling time is 30 minutes. Put 360g of aluminum powder in the ball mill to continue ball milling, and add 3600g of balls at the same time. After adding aluminum powder, the ball milling speed is 350 rpm, and the ball milling time is 1 hour. After the ball milling, take out 110g of mixed powder from the ball mill tank to fill the brake disc. The raw material of the inner 1 / 4 part, and then continue to add 135gMoS to the ball mill tank 2 and 97g titanium-coated diamond powder, MoS 2 The particle size of the powder is controlled at 5-10 microns, and the particle size of the titanium-coated diamond is controlled at 10-15 microns. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com