Electric cable wire checkup system and method

A technology for calibrating wires and cables, which is applied in the field of cable calibrating systems and calibrating lines. It can solve problems such as error-prone, many operations, and low calibrating efficiency, and achieve effective calibrating, high calibrating efficiency, and improved calibrating accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

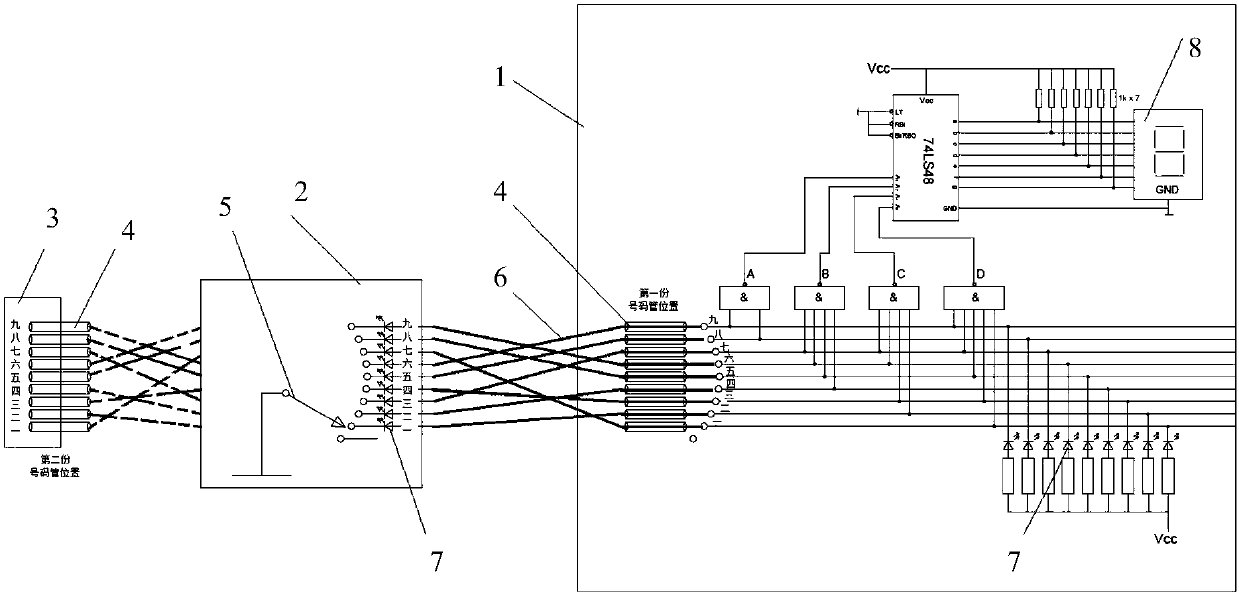

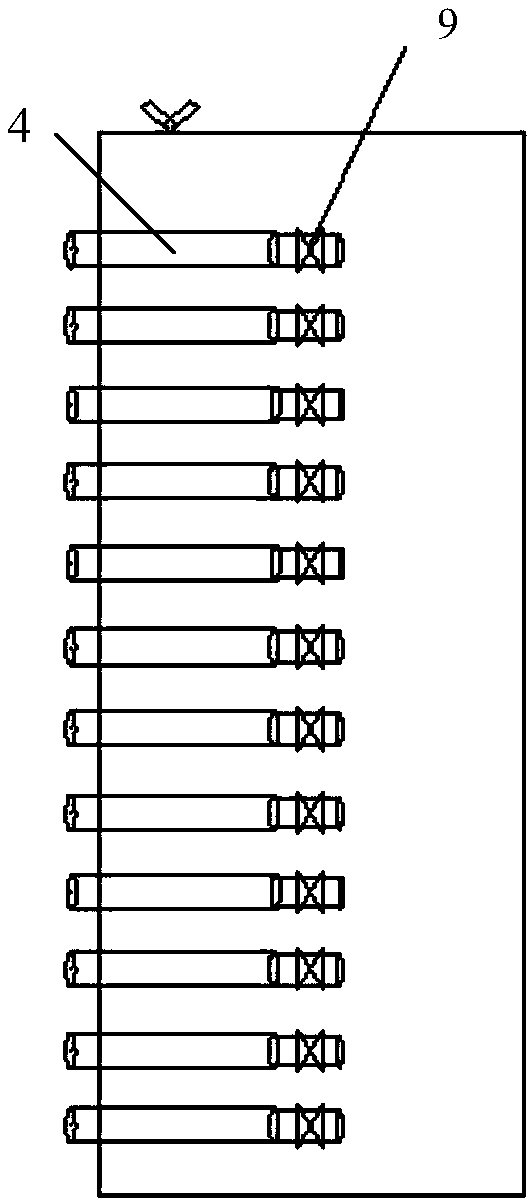

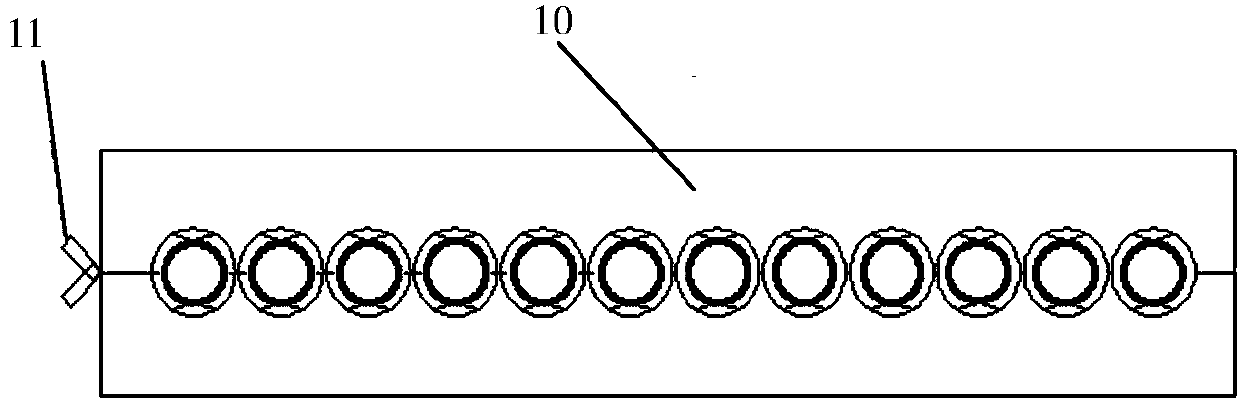

[0028] Such as figure 1 , figure 2 and image 3 As shown, a cable alignment system, the cable includes nine core wires 6, the alignment system includes a first alignment box 1 and a second alignment box 2, the side of the first alignment box 1 is provided with multiple The core wires 6 correspond to the reserved holes one by one, the number tube 4 is inserted in the reserved hole, the number tube 4 is provided with the core wire number, and the first calibration box 1 is provided with a display 8 and a plurality of core wires connected with the cable. The light-emitting diodes 7 corresponding to the wires 6 one-to-one, the second calibration box 2 is also provided with a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com