Light temperature increase self-adaptive ultrasonic dental descaler

An adaptive, ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as reduced work efficiency, high temperature, serious heat generation, etc., to improve stability and reliability , the resonance point drift is small, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

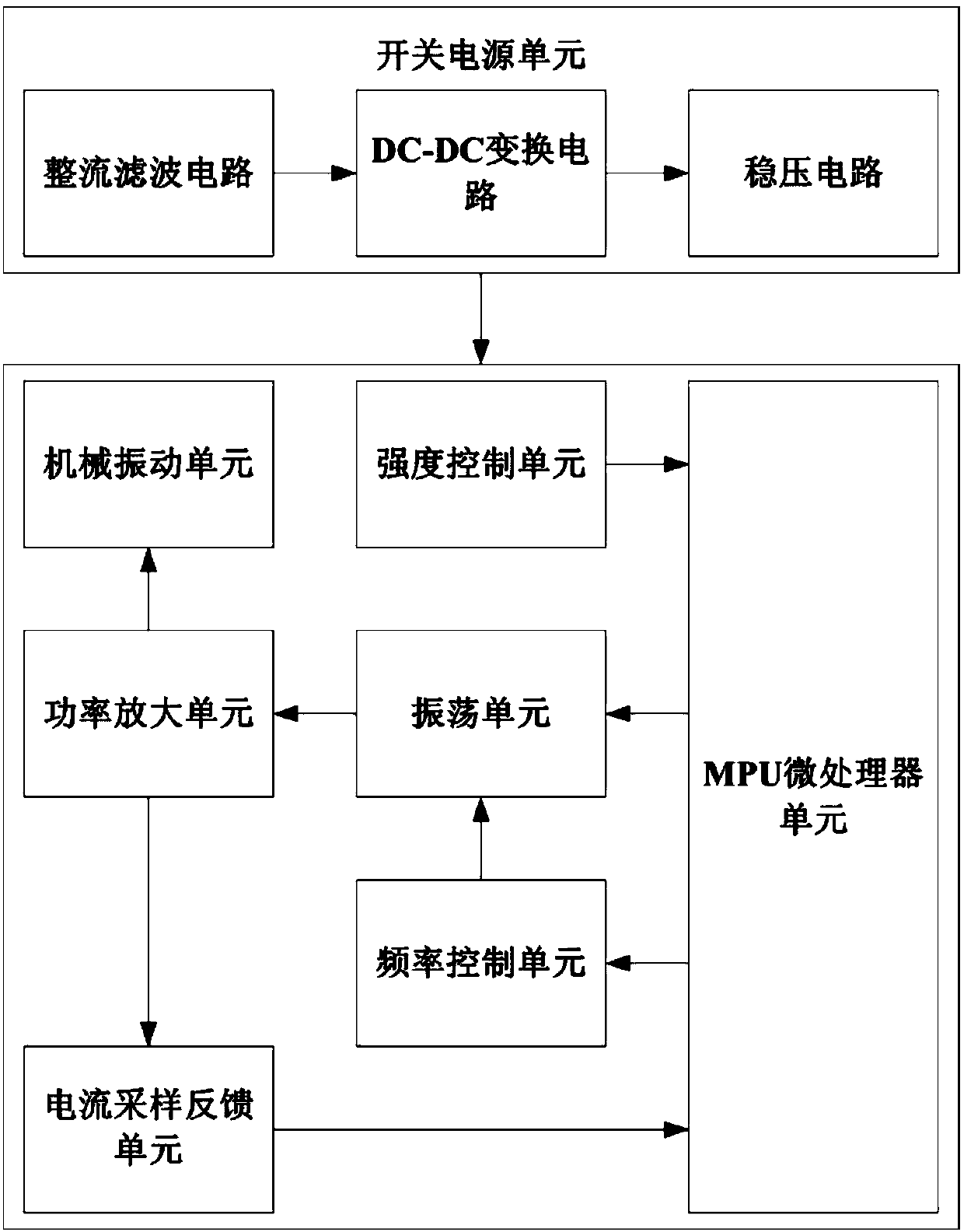

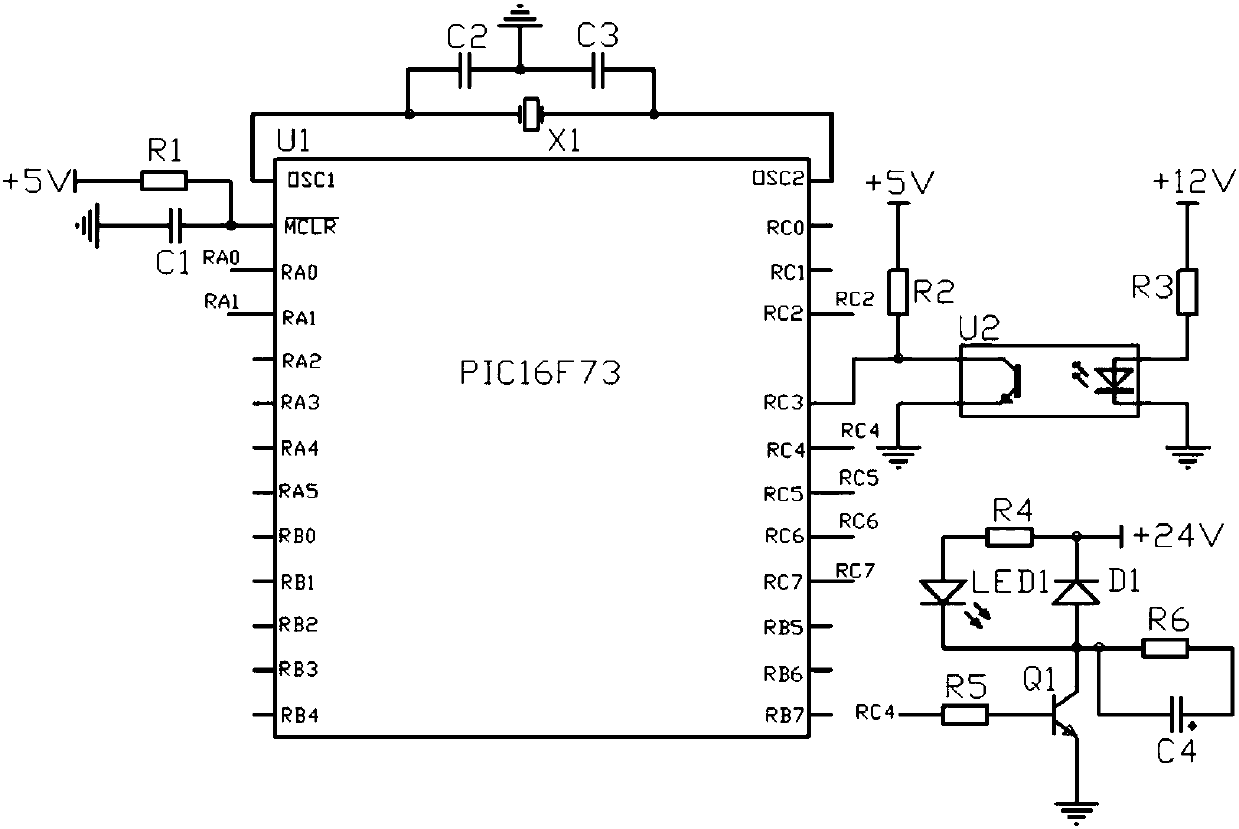

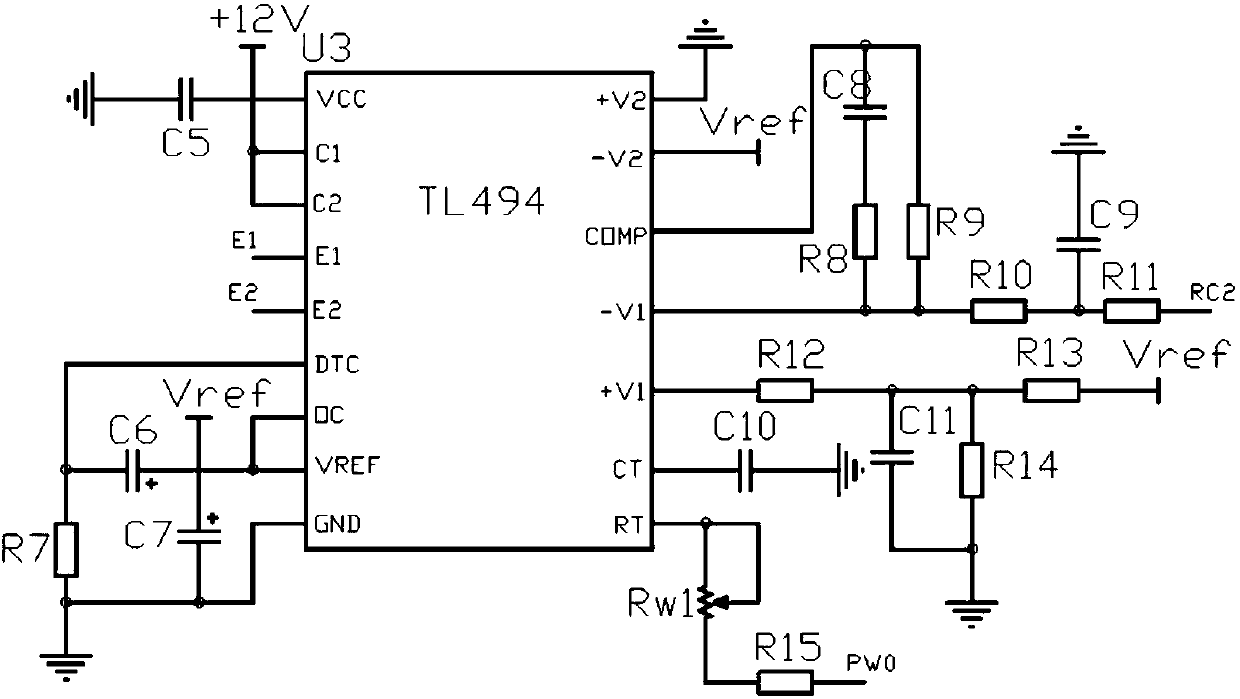

[0029] Such as figure 1 As shown, a low-temperature-rise self-adaptive ultrasonic dental scaler includes an MPU microprocessor unit, an oscillation unit, a frequency control unit, an intensity control unit, a power amplification unit, a current sampling feedback unit, a mechanical vibration unit and a switching power supply unit; The unit generates a push-pull pulse output with a controllable duty ratio under the control of the MPU microprocessor unit, and the MPU microprocessor unit sends data to the frequency control unit to control the oscillation frequency of the oscillation unit, so that the oscillation signal generated by the oscillation unit occupies The air ratio and frequency are controlled by the MPU microprocessor unit, and the oscillation signal is amplified by the power amplifier unit to drive the mechanical vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com