Millimeter wave adjustable filter

A filter and millimeter wave technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of difficult processing technology, small variable capacitance ratio, and low Q value, so as to improve system sensitivity and dynamic range, reduce The effect of small device volume and weight, and small dielectric constant of liquid crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

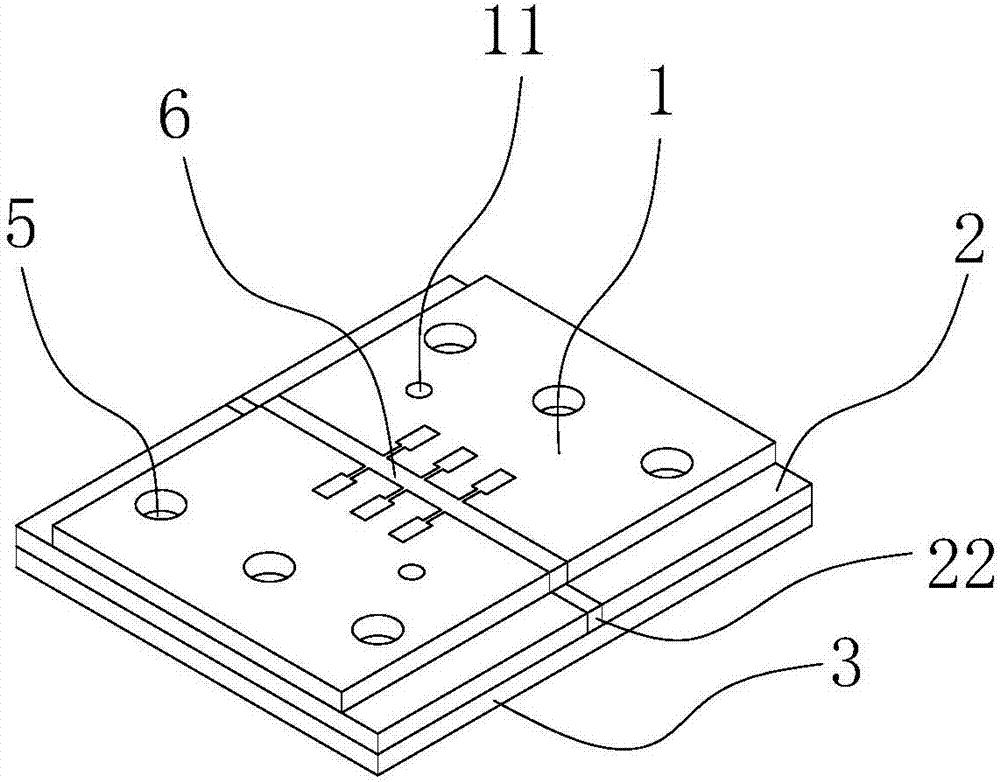

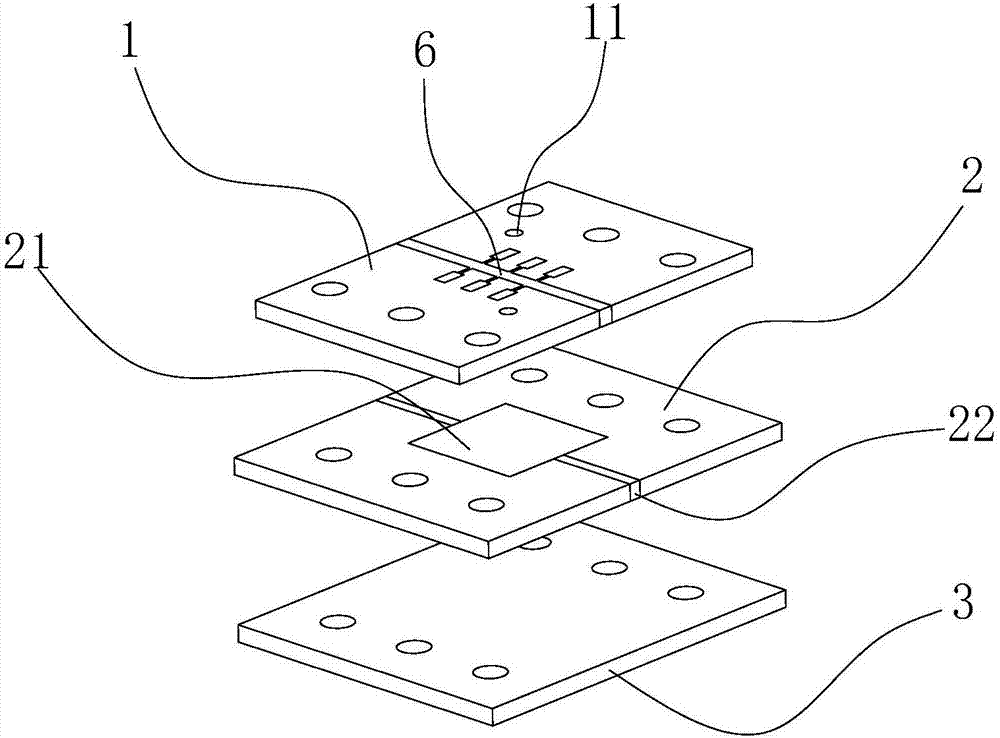

[0044] The millimeter wave tunable filter structure described in the present invention, such as figure 1 with figure 2 The shown includes an upper substrate 1, a lower substrate 2, and a metal carrier 3;

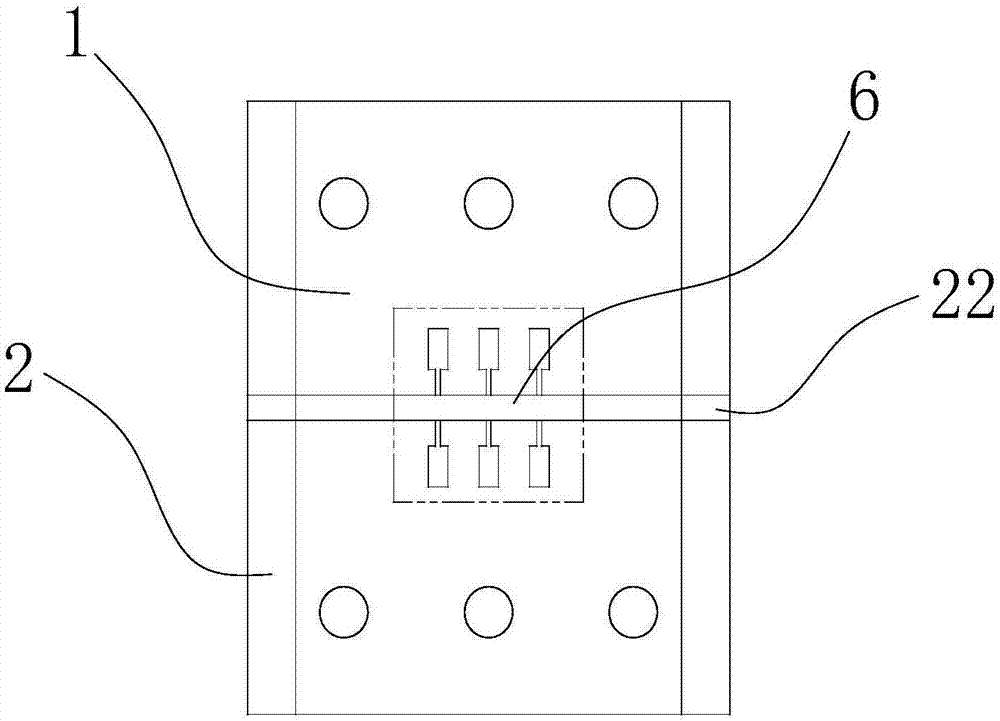

[0045] The upper substrate 1 is provided with a millimeter-wave tunable filter inverted microstrip circuit 6; the center of the lower substrate 2 is provided with a liquid crystal cavity, and the liquid crystal cavity is filled with liquid crystals 21, and two sides of the liquid crystal cavity are provided with A feeder 22 electrically connected to the liquid crystal 21;

[0046] The millimeter-wave tunable filter inverted microstrip circuit 6 includes 3 groups of microstrip hairpin resonators with hybrid coupling

[0047] The upper substrate 1, the lower substrate 2, and the metal carrier 3 are sequentially arranged from top to bottom; the microstrip metal wire 62 in the inverted microstrip circuit 6 of the millimeter-wave tunable filter is closely combined with the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com