Torsion damper assembly for crankshaft

A torsional shock absorber and crankshaft technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, portable lifting device, etc., can solve the problem of cogging runout accuracy and reduce the crankshaft torsional shock absorber assembly in the axial direction. Series motion and torsional vibration amplitude, vibration damping rubber ring shear fatigue and other issues, to achieve the effect of reducing torsional vibration, improving reliability and fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

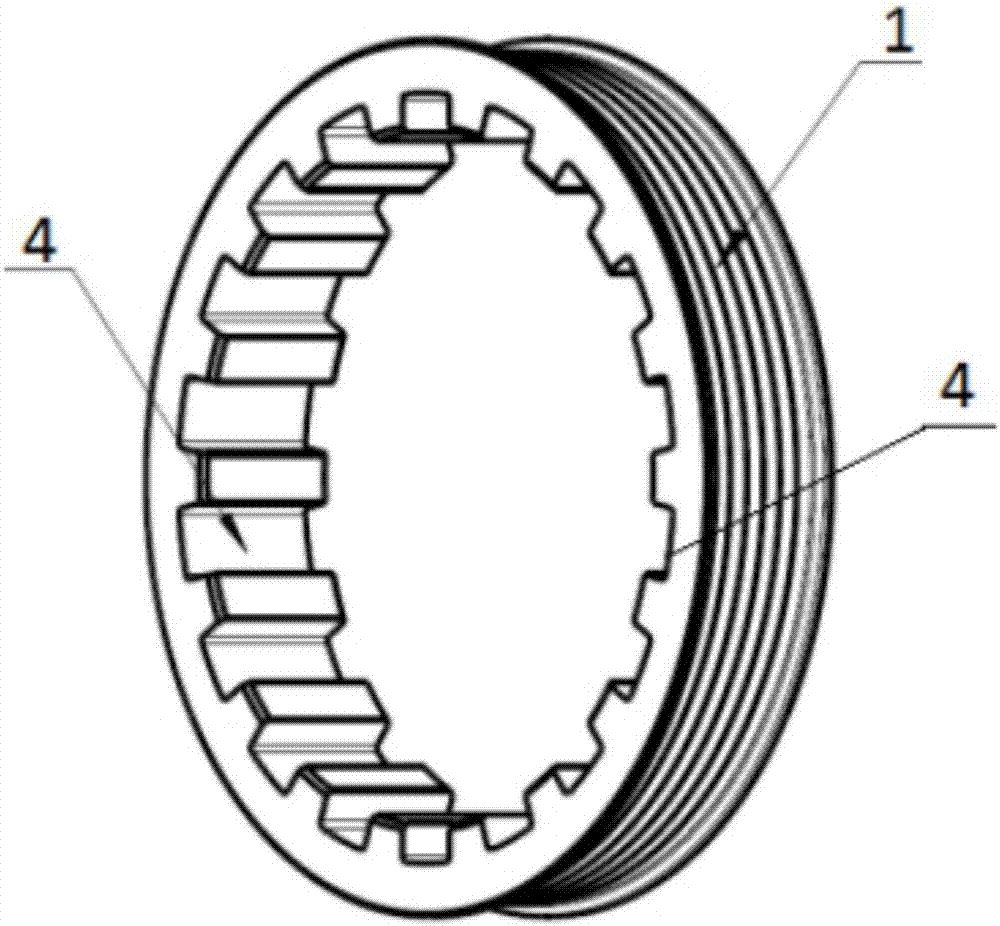

[0021] see figure 1 A crankshaft torsional damper assembly shown includes a pulley 1 and a hub 3 that is mated with the crankshaft, and is characterized in that: it also includes a pulley located between the inner circle of the pulley 1 and the outer circle of the hub 3 The damping rubber ring 2.

[0022] see figure 2 , the inner circle of the pulley 1 is equidistantly provided with a plurality of large grooves 4 of the same size, and the outer circle is provided with belt grooves.

[0023] see image 3 , the outer circle of the vibration-damping rubber ring 2 is equidistantly provided with a plurality of large bosses 5 of the same size, and the inner circle is equidistantly provided with a plurality of small grooves 6 of the same size, and each of the large bosses 5 Number is equal to the number of the large groove 4;

[0024] see Figure 4 , the outer circle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com