Medium temperature sintered microwave dielectric material with medium dielectric constant and high Q value

A technology of microwave dielectric materials and microwave dielectric ceramics, which is applied in the field of microwave dielectric materials and preparation, can solve the problems of difficulty in meeting the development requirements of high-performance microwave device integration, low quality factor, high sintering temperature, etc., and achieves high Q value, The effect of high density of porcelain and environmental protection in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

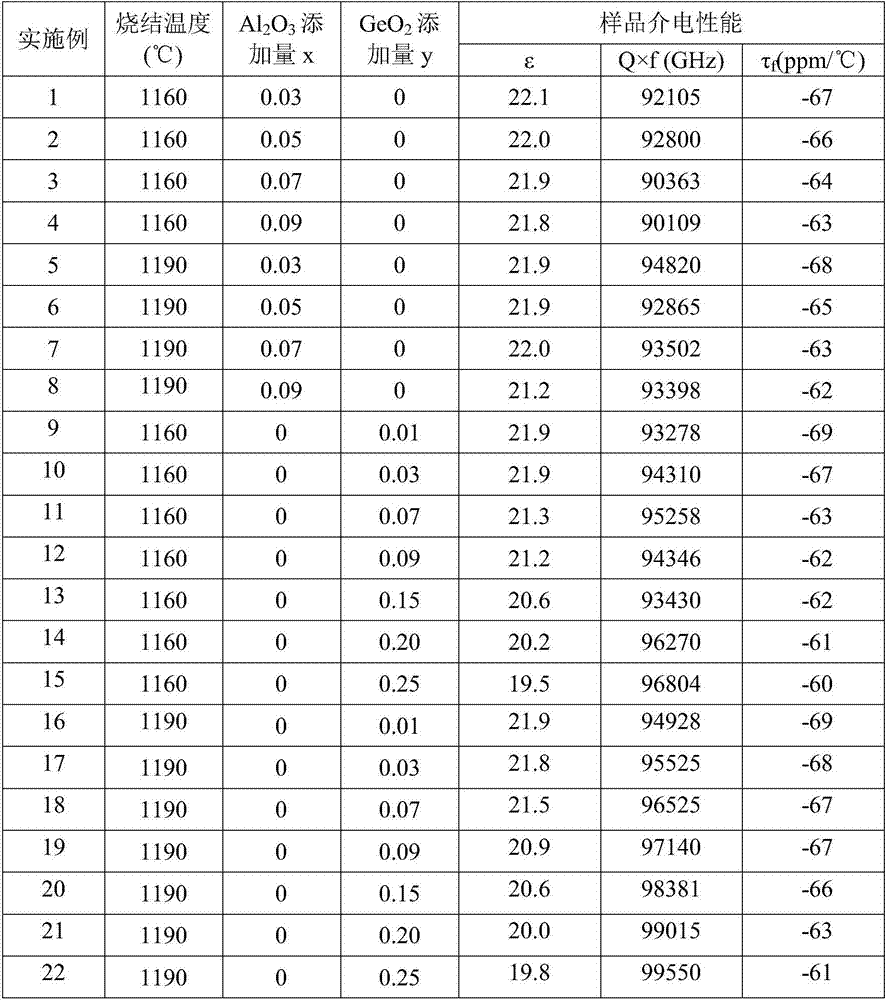

[0016] The present invention will be further described below through specific examples.

[0017] The preparation method of a medium-temperature sintered medium-permittivity high-Q microwave dielectric material of the present invention, the steps are as follows:

[0018] (1) the present invention adopts analytically pure raw material, ZnO, Nb 2 o 5 According to the mass molar percentage of 3:1, mixed with absolute ethanol, ball milled for 8 hours, dried and pre-fired at 1075°C for 4 hours to obtain Zn 3 Nb 2 o 8 Solid particles;

[0019] (2) Step (1) pre-burns the gained Zn 3 Nb 2 o 8 The solid particles are subjected to secondary ball milling in absolute ethanol for 8 hours, and after drying, pass through a 80-mesh sieve to obtain Zn 3 Nb 2 o 8 powder;

[0020] (3) Gained Zn in step (2) 3 Nb 2 o 8 In powder, according to (1-x)Zn 3 Nb 2 o 8 -xAl 2 o 3 -yGeO 2 , where the stoichiometric formula of 02 o 3 with GeO 2 , ball milled in absolute ethanol for 8 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com