Novel cement-based anti-impact paste slurry and preparation method thereof

A cement-based and paste slurry technology, applied in the field of cement-based paste paste technology, can solve problems such as difficulty in meeting large-flow water scouring, technical and economic effects difficult to meet engineering requirements, etc., and achieve excellent underwater non-dispersibility and excellent resistance to water flow. diluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments and accompanying drawings. The embodiments of the present invention are for better understanding of the present invention by those skilled in the art, and do not limit the present invention in any way.

[0026] A kind of novel cement base anti-shock paste of the present invention, its composition is as follows:

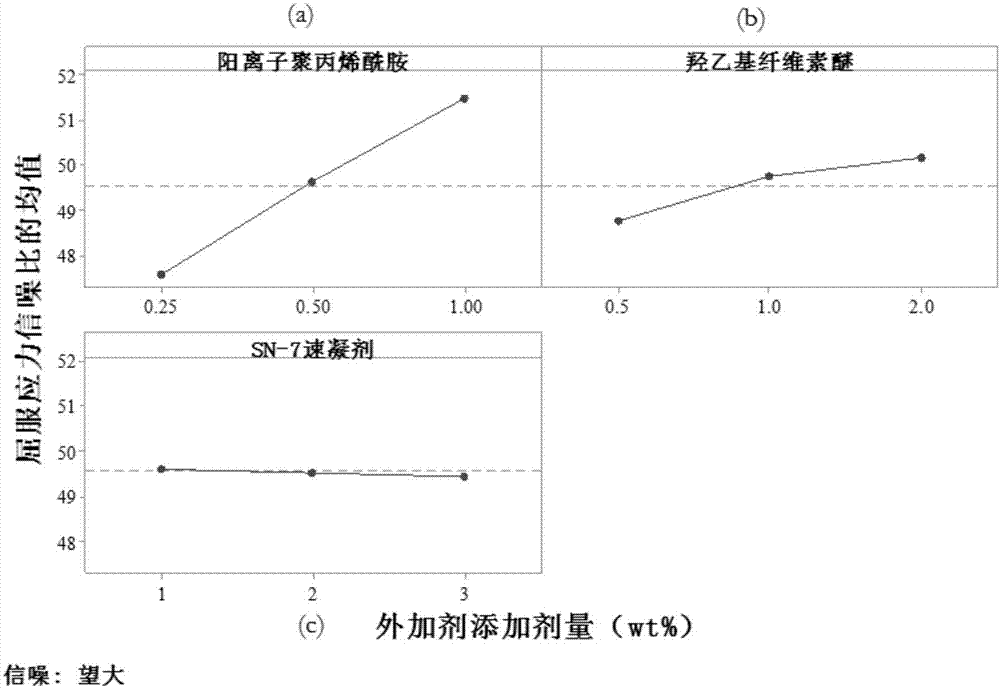

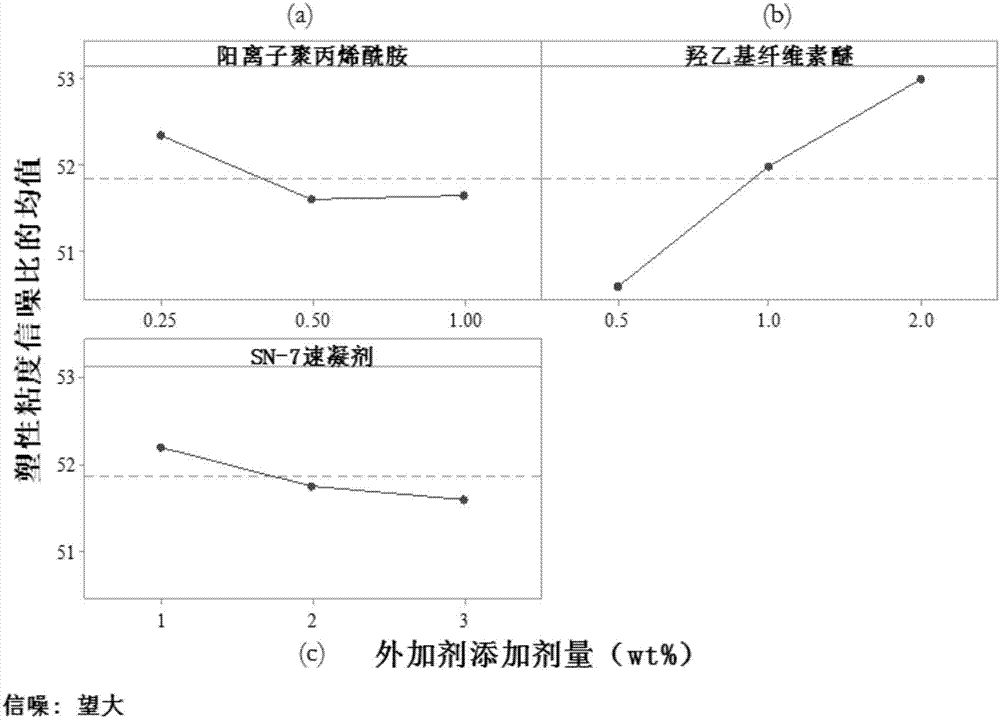

[0027] At a water-cement ratio of 0.48 ~ In the 0.51 plain cement slurry system, cationic polyacrylamide 1wt%, hydroxyethyl cellulose ether 2wt%, SN-7 accelerator 1wt%,

[0028] Among them: wt% is the dosage unit, representing the weight percentage of the cement that the additive content occupies;

[0029] The chemical composition of the SN-7 quick-setting agent is: 2% of water reducing agent, 81% of sodium metaaluminate, 12% of calcium silicate and 5% of sodium ferroaluminate.

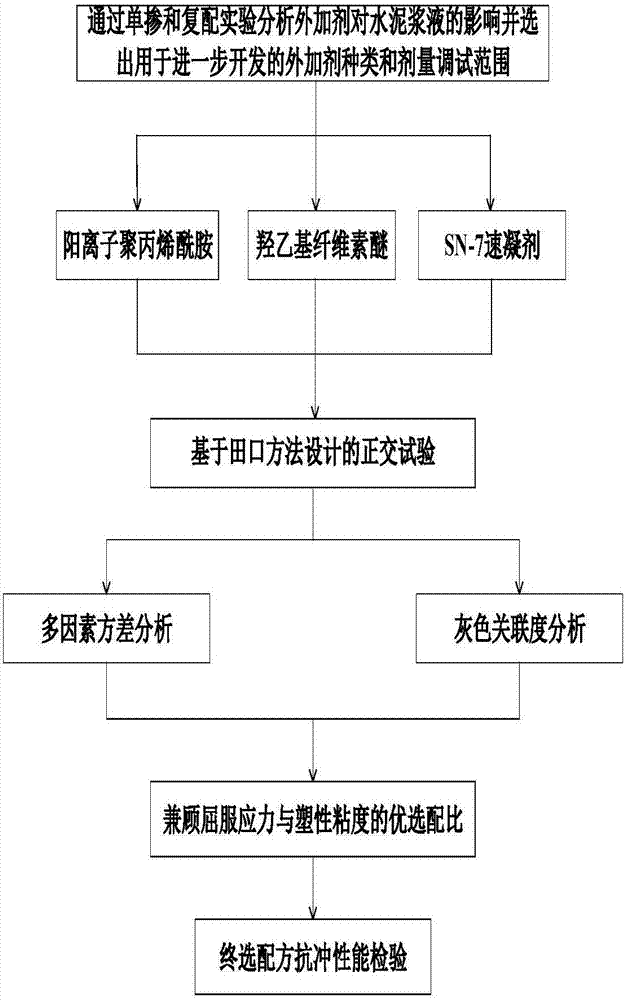

[0030] like figure 1 As shown, it is a new type of cement-based anti-shock slurry process, includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Initial setting time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com