Lathe clamp for machining blade dehumidification groove

A vehicle fixture and blade technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of no fixture, the blade dehumidification tank cannot be processed, and the processing technology of the blade dehumidification tank is inconvenient, so as to improve production efficiency, Processing quality leaps to ensure the effect of processing and production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

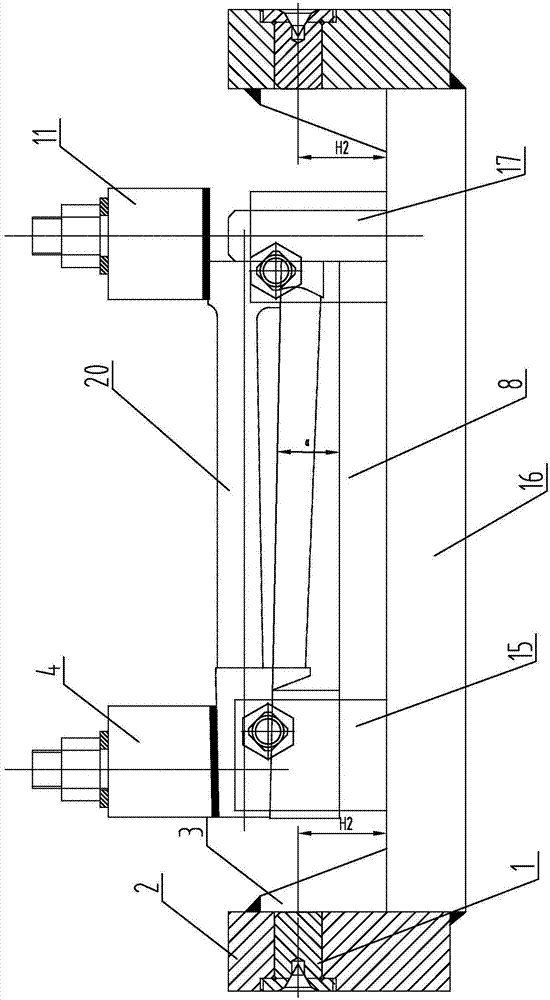

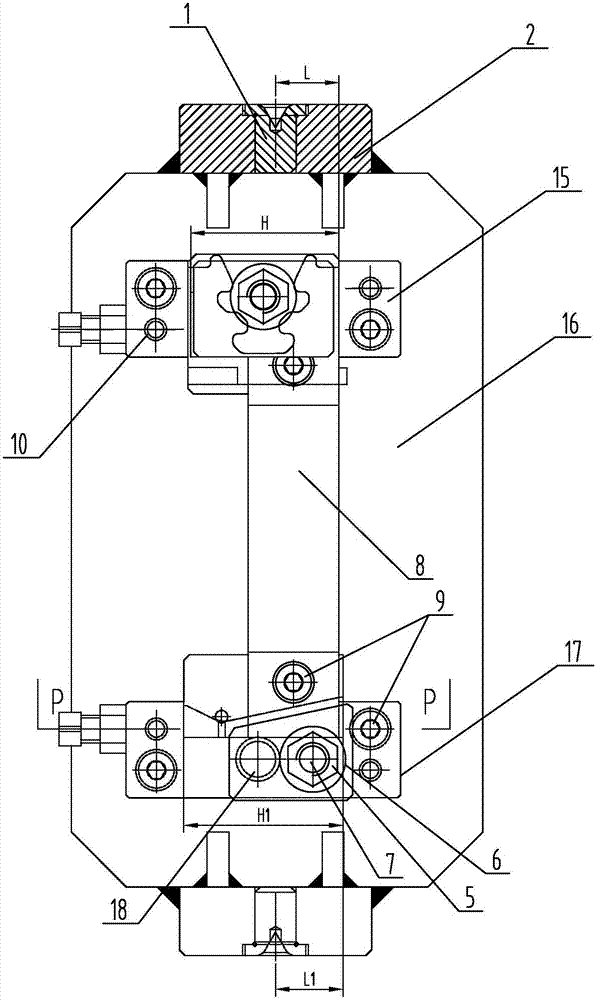

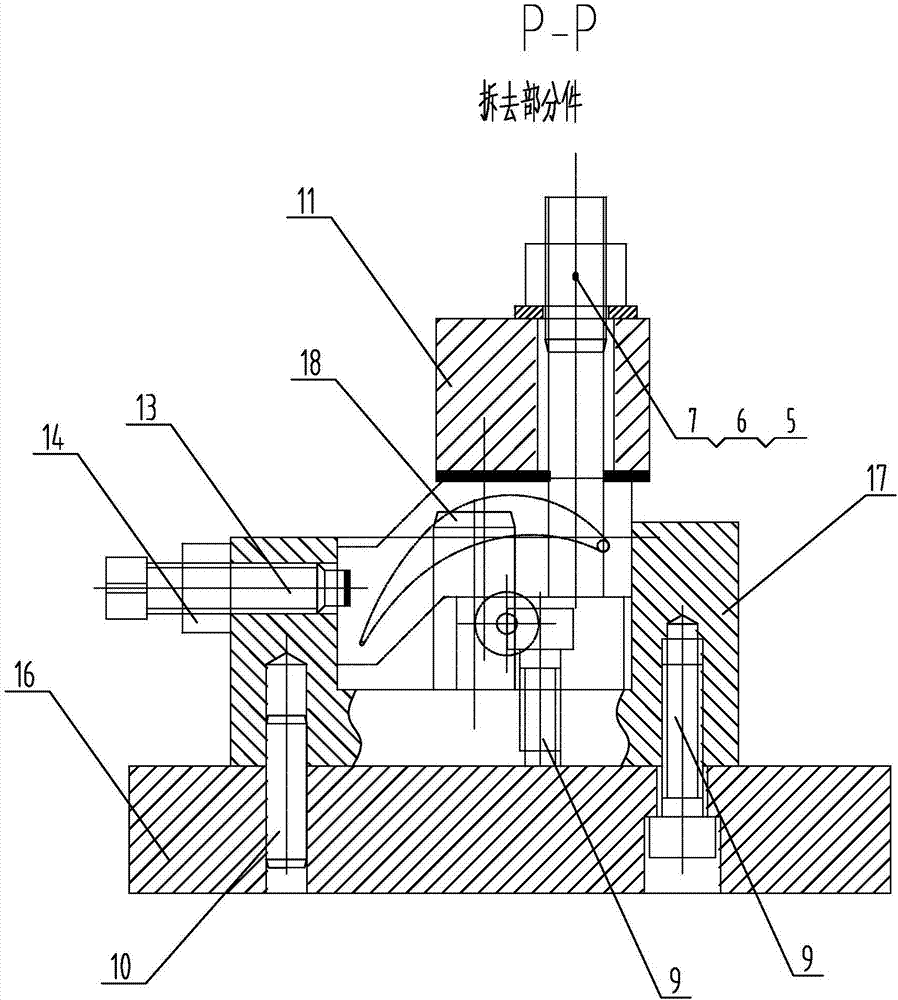

[0014] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment. This embodiment includes a fixture main part, a positioning part and a clamping part. The blade 20 is installed on the fixture main part through the positioning part and the clamping part. The fixture main part includes two thimble seats 2 and two sets of ribs. The plate 3 and the bottom plate 16, the bottom plate 16 is a strip-shaped bottom plate, two thimble holders 2 are respectively installed on the two width directions of the bottom plate 16, and the joints of the two thimble holders 2 and the bottom plate 16 are respectively connected by a group of ribs 3 The positioning part includes the positioning part of the inner radial surface of the blade, the positioning part of the steam inlet edge of the blade root and the blade crown and the positioning part of the blade length direction, the positioning part of the inner radial surface of the blade is installed on the blade root po...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 2 and image 3 To illustrate this embodiment, the main part of the fixture in this embodiment also includes two thimble sleeves 1, each thimble base 2 is provided with a thimble sleeve installation hole, and each thimble sleeve installation hole is equipped with a thimble sleeve 1, and the thimble sleeve 1 There are thimble holes on the outside. In this way, the installation hole of the thimble sleeve is a stepped hole, which serves as the dehumidification rotation center. There are 2 purposes for the thimble sleeve to be designed as a stepped shape. One is to increase its rigidity to avoid deformation of the thimble positioning part of the fixture due to excessive clamping force when the lathe is clamped. The other is for the replaceability of the fixture. The thimble sleeve is an easy-wearing part. , The thimble hole is severely worn. In order to ensure the processing accuracy, the thimble sleeve is replaced reg...

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 and image 3 Describe this embodiment, the blade inner radial surface positioning part of this embodiment includes the inner radial surface positioning block 8, the inner radial surface positioning block 8 is installed on the blade root positioning seat 15 and the blade shroud positioning seat 17, the inner radial surface positioning block 8 The radial angle matches the contact surface angle where the blades 20 meet. Such arrangement facilitates the positioning of the inner radial surface of the blade 20 . Other compositions and connections are the same as those in the second embodiment.

[0021] The radial angle of the positioning block 8 on the inner radial surface in this embodiment is α, and the value of α is consistent with the radial angle of the blade. The design in the width direction only needs to consider not interfering with the inner wing angle of the blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com