A method for preventing wall sticking in the preparation of traditional Chinese medicine granules by spray drying

A traditional Chinese medicine and drying technology, which is applied in pharmaceutical formulations, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc. Easy to stick wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

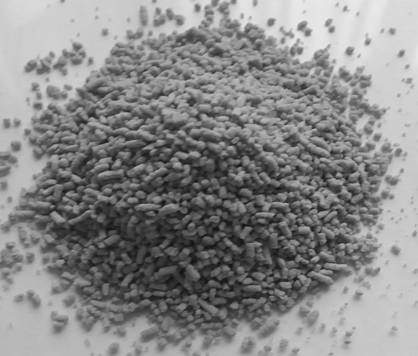

Image

Examples

Embodiment 1

[0029] A method of preventing adhesive walls in a spray drying agent particles, the specific method is as follows:

[0030] (1) Grind the Valley dice to the fine powder, over 100 mesh sieve, spare;

[0031] (2) Grind the agar to the fine powder, over 100 mesh sieve, spare;

[0032] (3) Take 100kg solid content of 15% mulberry concentrate to the stirred tank, then add 0.5 kg of step (1), the fine grain powder prepared, stirred at 50-100 rpm of rotational speed for 30 min, and the temperature of the stirred tank is 70. -80 ° C, so that the fine valley powder is evenly dispersed and ripe, and the osmium concentrate is concentrated, and the fine particles are fully adsorbed to the network structure of the cereal powder.

[0033] (4) Take the fine agar powder prepared by 0.3 kg step (2), add 2 kg of hot water to pre-dissolved, then add step (3), agitate, stir well;

[0034] (5) The material obtained by step (4) is continuously fed into the spray drying nozzle, and the first stage dryin...

Embodiment 2

[0038] A method of preventing adhesive walls in a spray drying, a method of preventing adhesive walls, and the specific method is as follows:

[0039] (1) Grind the Valley dice to the fine powder, over 100 mesh sieve, spare;

[0040] (2) Grind the agar to the fine powder, over 100 mesh sieve, spare;

[0041] (3) Take 100KG solid content of 20% of the macar concentrate to add a stirred tank, then the fine grain powder prepared by 0.8 kg of step (1), stirred at 50-100 rpm of rotational speed for 30 min, and the temperature of the stirred tank is 70. -80 ° C, make the fine valley powder uniformly dispersed and ripened, and the discharged from 24h, the soluble component in the concentrate of the Chinese medicine was concentrated, and the fine particles were fully adsorbed to the network structure of the cereal powder;

[0042] (4) Take the fine agar powder prepared by 0.5 kg step (2), add 2 kg of hot water to pre-dissolving, then add step (3), agitate the material, stir well;

[0043]...

Embodiment 3

[0047] A method of preventing adhesive walls in a spray drying, and the specific method is as follows:

[0048] (1) Grind the Valley dice to the fine powder, over 100 mesh sieve, spare;

[0049] (2) Grind the agar to the fine powder, over 100 mesh sieve, spare;

[0050] (3) Take 100kg solid content of 25% astragal concentrate to add a stirred tank, then the fine grain powder prepared by 0.5 kg step (1), stirred at 50-100 rpm of rotational speed for 40 min, and the temperature of the stirred tank is 70- 80 ° C, so that the fine valley powder is uniform and ripened, and the discharged from 24h, the soluble component in the concentrate of the Chinese medicine is concentrated, and the fine particles are fully adsorbed on the network structure of the cereal powder;

[0051] (4) Take the fine agar powder prepared by 0.3 kg step (2), add 4 kg of hot water to pre-dissolved, then add step (3), agitate the agitation, stir well;

[0052] (5) The material obtained by step (4) is continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com