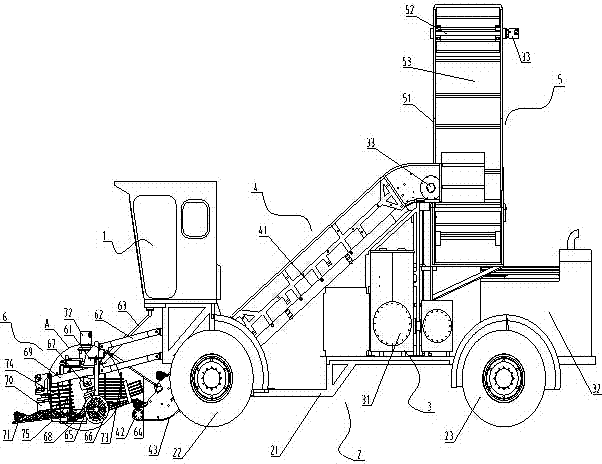

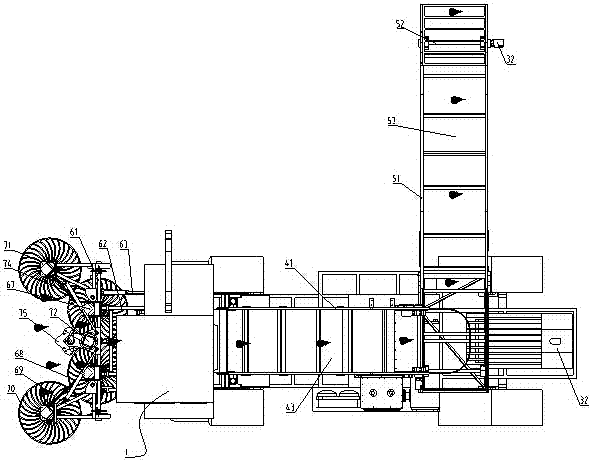

Rotating disc type beet loader

A technology of loader and turntable type, which is applied to loaders, agricultural machinery and implements, and other applications. It can solve the problems of poor versatility of parts, high procurement costs, and poor adaptability, and achieve small material damage, adjustable working width, and easy picking. The effect of increased width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

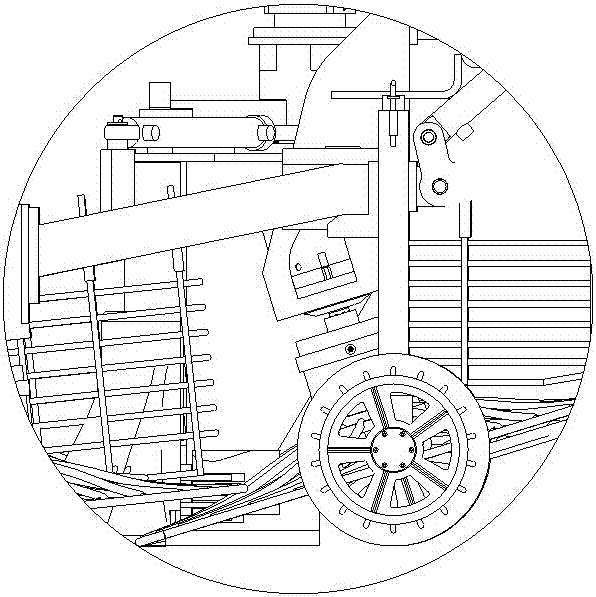

[0021] refer to Figure 1-Figure 5 , a kind of turntable type sugar beet loader of the present invention, comprises material picking part 6, walking part 2, power part 3, first conveying part 4, second conveying part 5 and driver's cab 1, and described walking part 2 comprises vehicle frame 21 , front wheel 22 and rear steering wheel 23, described front wheel 22 and rear steering wheel 23 are installed on the vehicle frame 21 respectively, and described rear steering wheel 23 is used for controlling the displacement direction of walking part 2, and described vehicle frame 21 left The material picking part 6 is installed on the side, and the material picking part 6 includes a lifting frame 61, a connecting rod 62, a lifting adjustment hydraulic cylinder 63, a distance adjusting rod 64, a ground wheel frame 65, a ground wheel 66, and a first material picking hydraulic motor 67. , the first pick-up tray 68, the extension arm 69, the second pick-up hydraulic motor 70, the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com