Spliced board process side and board splicing method

A technology of edge and splicing, applied in the field of electronics, can solve the problem that the test results of test strips or test modules cannot truly reflect the graphics unit, uneven thickness of the dielectric layer of PCB splicing, etc., and achieve uniform current density distribution and edge Symmetrical margin, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention, and do not limit the protection scope of the present invention.

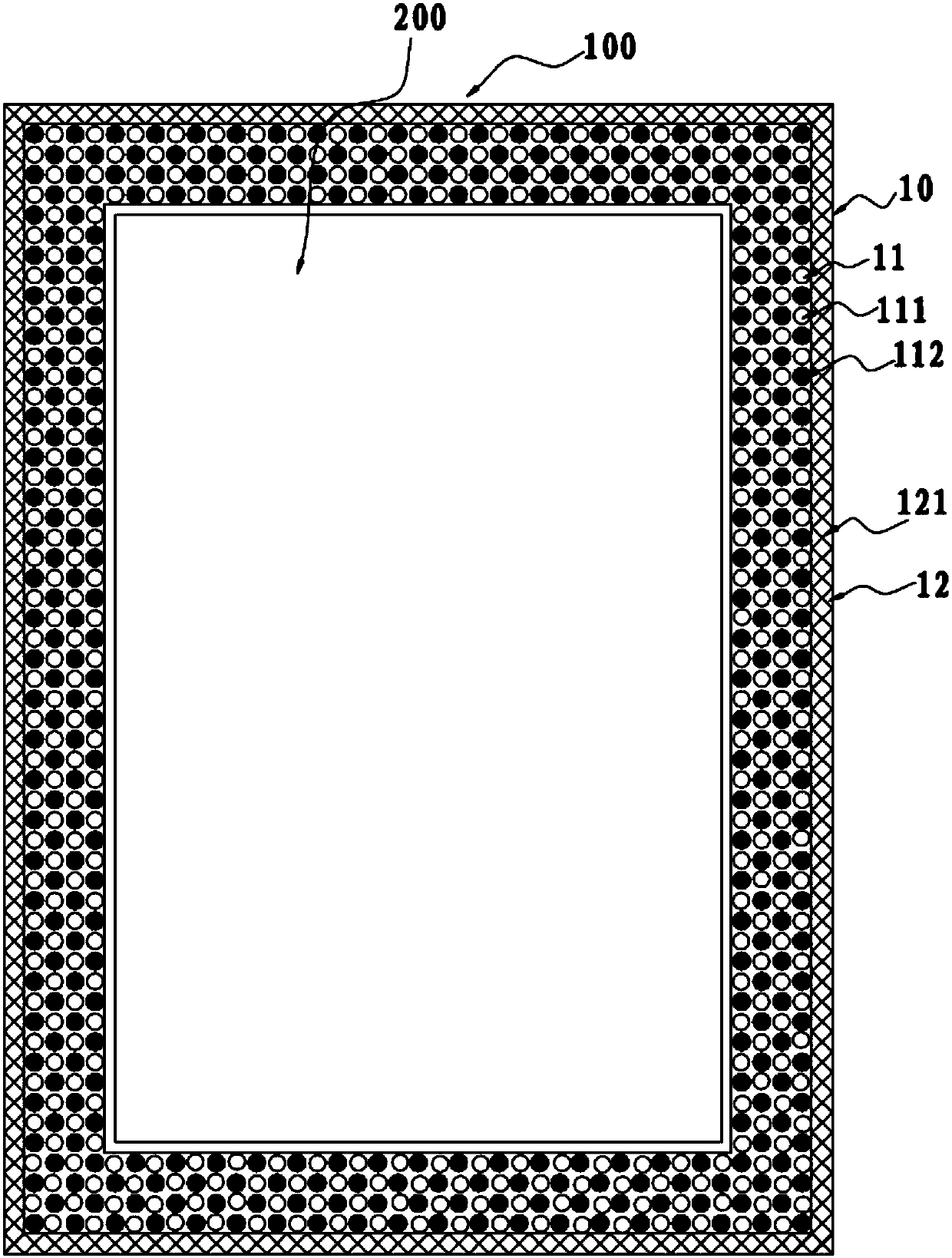

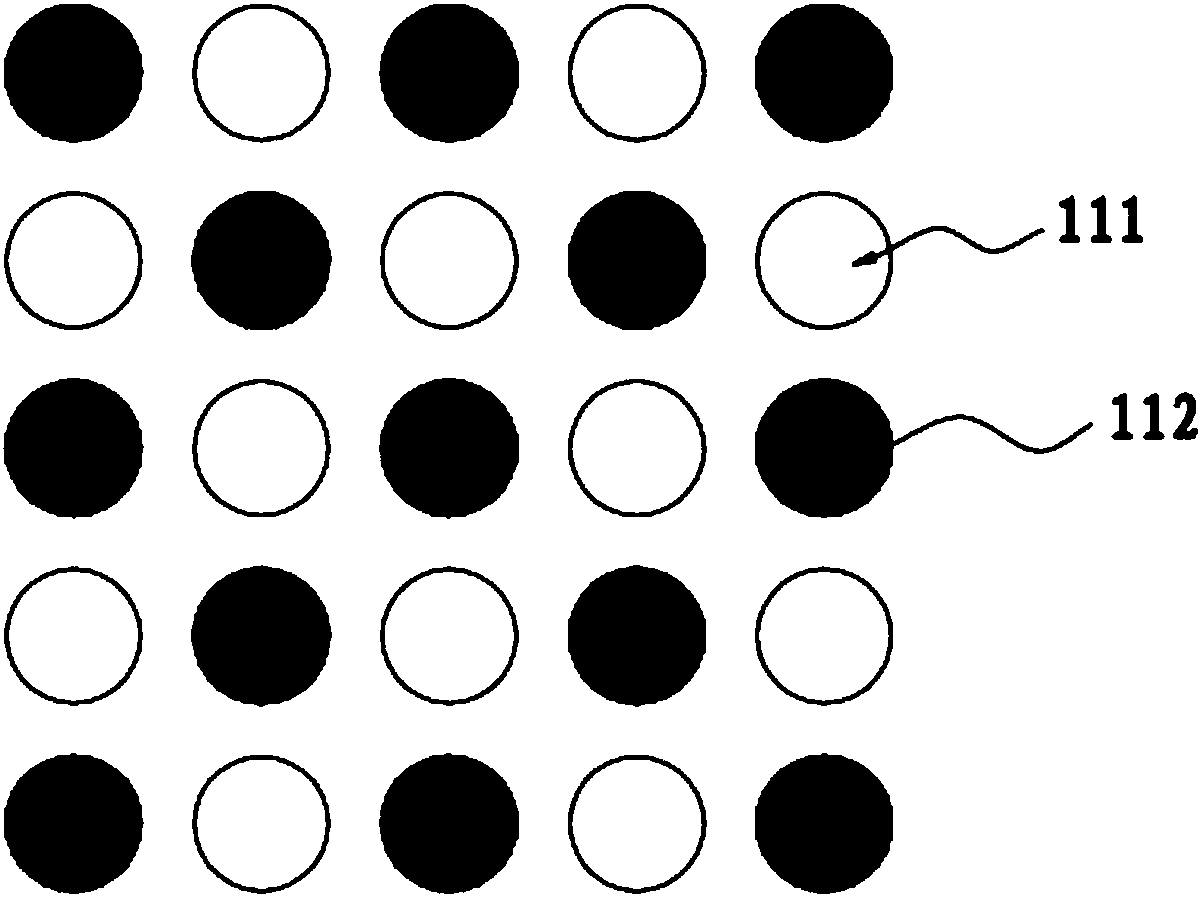

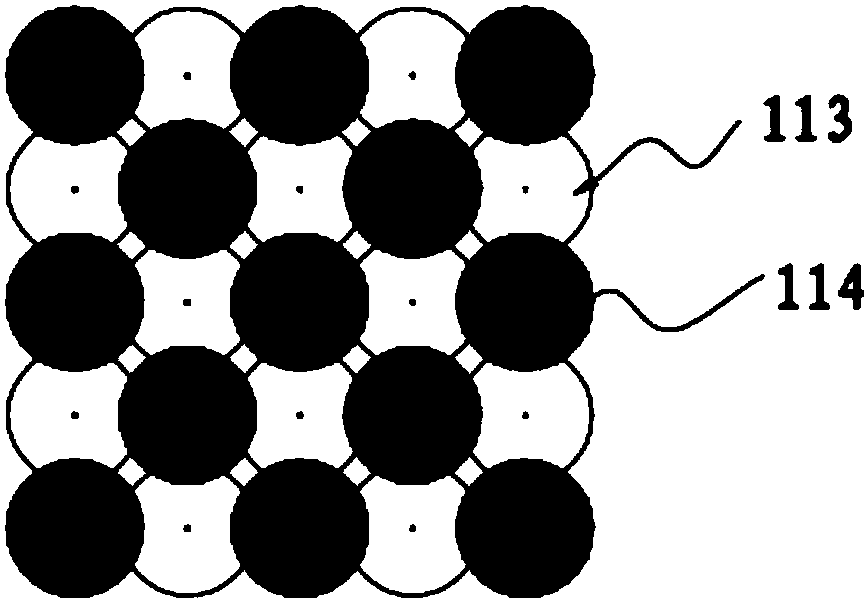

[0035] Such as figure 1 A panel process edge 100 as shown is arranged on the periphery of the graphic unit 200 of the circuit board, including: at least two layers of process edges 10 stacked, each layer of process edge 10 is provided with a balance copper point 11, and each layer The residual copper ratio of the process edge 10 is the same as the residual copper ratio of the pattern unit 200 of the corresponding layer.

[0036] The jigsaw process edge 100 of this embodiment has the same laminated layer as the jigsaw graphics unit 200, and the jigsaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com