Neutron generator tube

A technology for generating tubes and neutrons, applied in the direction of DC voltage accelerators, etc., can solve the problem of not reaching the sharp cut-off of the neutron pulse waveform, and achieve the effect of shortening the delay time, reducing the secondary electron emission, and reducing the disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and embodiments.

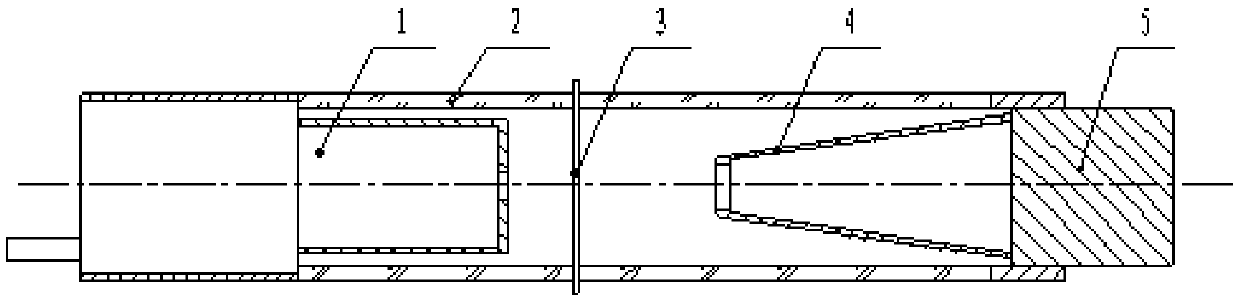

[0021] A neutron generating tube provided by the present invention includes an ion source 1, a housing 2, a grid 3, an accelerator 4 and a target 5. The shell 2 is made of quartz glass, and the inside is a vacuum cavity. A thin grid 3 is arranged between the ion source 1 and the accelerator 4 in the vacuum cavity. The grid 3 has a larger diameter than the shell Diameter, the plane of the grid 3 is perpendicular to the axis of the neutron generating tube and an annular step is formed outside the housing 2. The grid 3 is made of a metal molybdenum material and is provided with a mesh grid.

[0022] The grid power supply has an ideal square wave waveform, and the amplitude, frequency, and duty cycle are adjustable. The amplitude of the grid pulse voltage is between -1.5KV and +4KV, and the radius of the grid hole is 2.25mm.

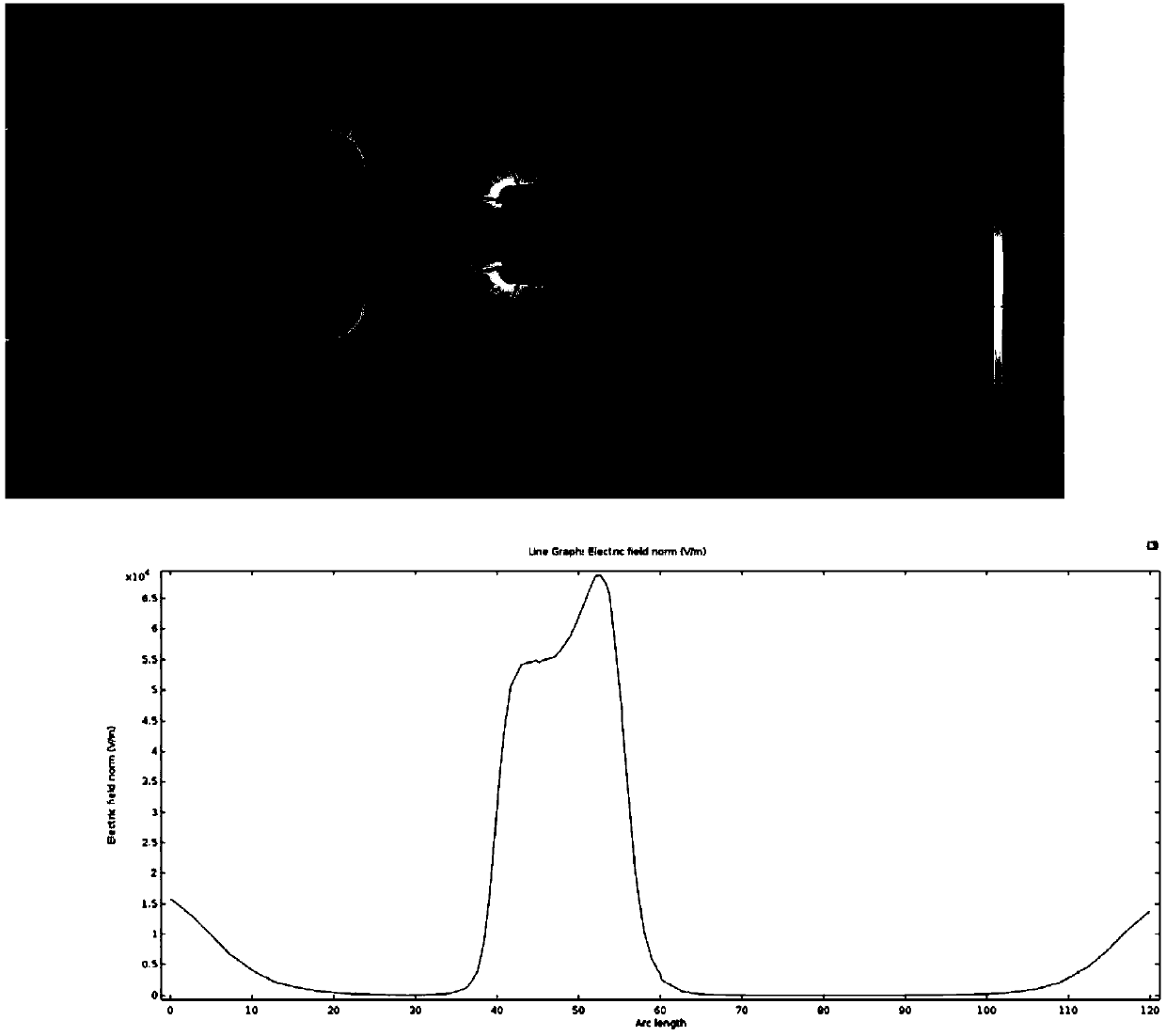

[0023] The working principle of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com