High-efficiency drying and stirring device

A stirring device, high-efficiency technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems affecting the drying efficiency and the transmission ratio of the device, so as to improve water evaporation, reduce energy consumption and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

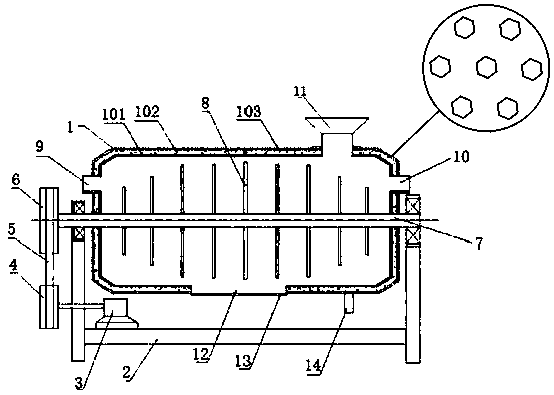

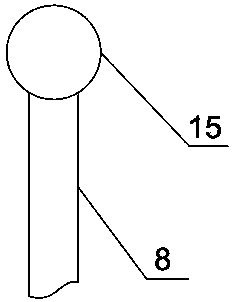

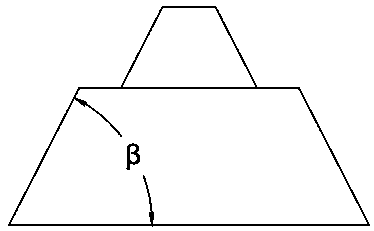

[0019] Such as Figure 1~3 As shown, a high-efficiency drying and stirring device includes a frame 2 and a drying box 1 arranged on the upper end of the frame 2. The upper end of the frame 2 is provided with a motor 3, and the motor 3 is connected to a rotating shaft 7, and the rotating shaft 7 is arranged on the drying box 1. In the center of the interior, a rotating rod 8 is connected to the surface of the rotating shaft 7, and the two ends of the rotating shaft 7 protrude from the drying box 1 and are fixed with the frame 2. The upper end of the drying box 1 is provided with a feed port 11, and the left side of the drying box 1 is provided with an air inlet 9. The air outlet 10 is provided on the right side of the drying box 1, and the material outlet 12 and the water outlet 14 are provided at the bottom of the drying box 1. The structure of the device is simple, easy to install and operate, and the structure of the frame 2 is stable, which can effectively support the rotati...

Embodiment 2

[0028] Such as Figure 1~3 As shown, a kind of high-efficiency drying and stirring device, when grain is dry, the dustproof cover 13 of material outlet 12 is closed, the dustproof cover of water outlet 14 is opened, and feed inlet 11 and air inlet 9 and outlet are pulled out. The dust-proof plug inside the tuyere 10 is used to pour grain into the drying box 1 from the feed port 11, turn on the motor 3 to make it work, the output shaft of the electrical appliance 3 drives the driving wheel 4 to rotate, and the driving wheel 4 drives the driven wheel through the belt 5 6 rotates, the driven wheel 6 makes the rotating shaft 7 rotate, and then the rotating rod 8 on the rotating shaft 7 turns the grain, and simultaneously feeds hot air into the air inlet 9, and the hot air passes through the grain and blows out from the air outlet 10 after taking away the moisture. The air is absorbed by the box of the drying box 1, and is conducted to the outside of the drying box 1 to evaporate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com