Track lamp

A track light and track technology, which is applied to the loss prevention measures of lighting devices, lighting and heating equipment, lighting devices, etc. Short and other problems, to achieve stable and reliable connection and electrical contact, improve light output, and eliminate the effect of dark areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

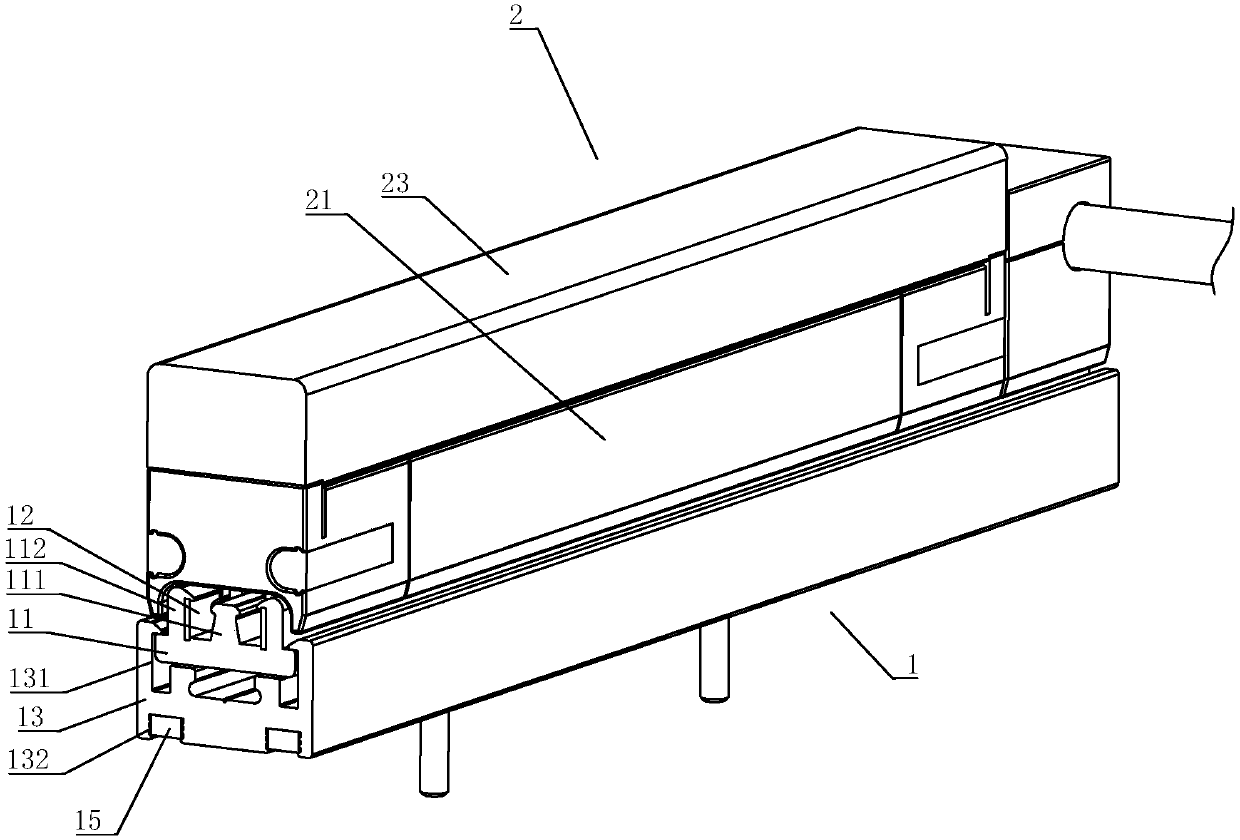

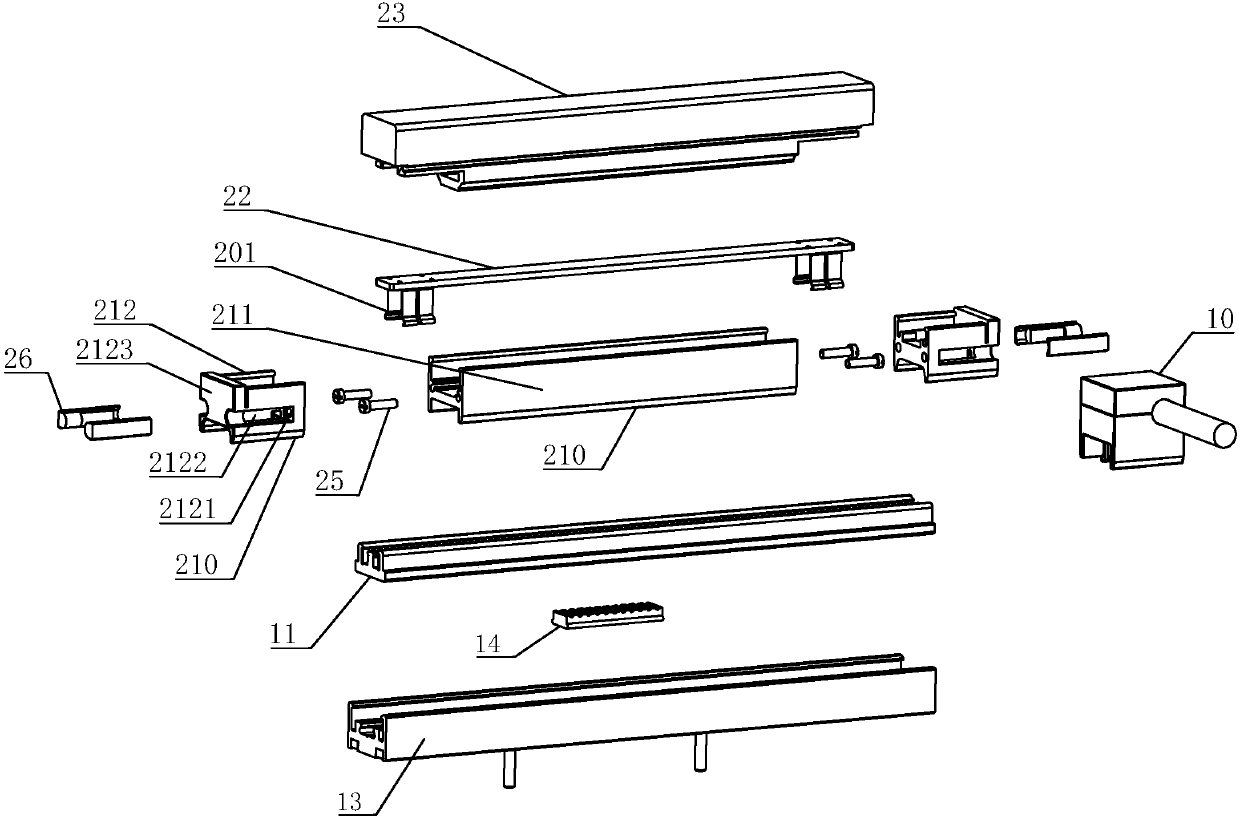

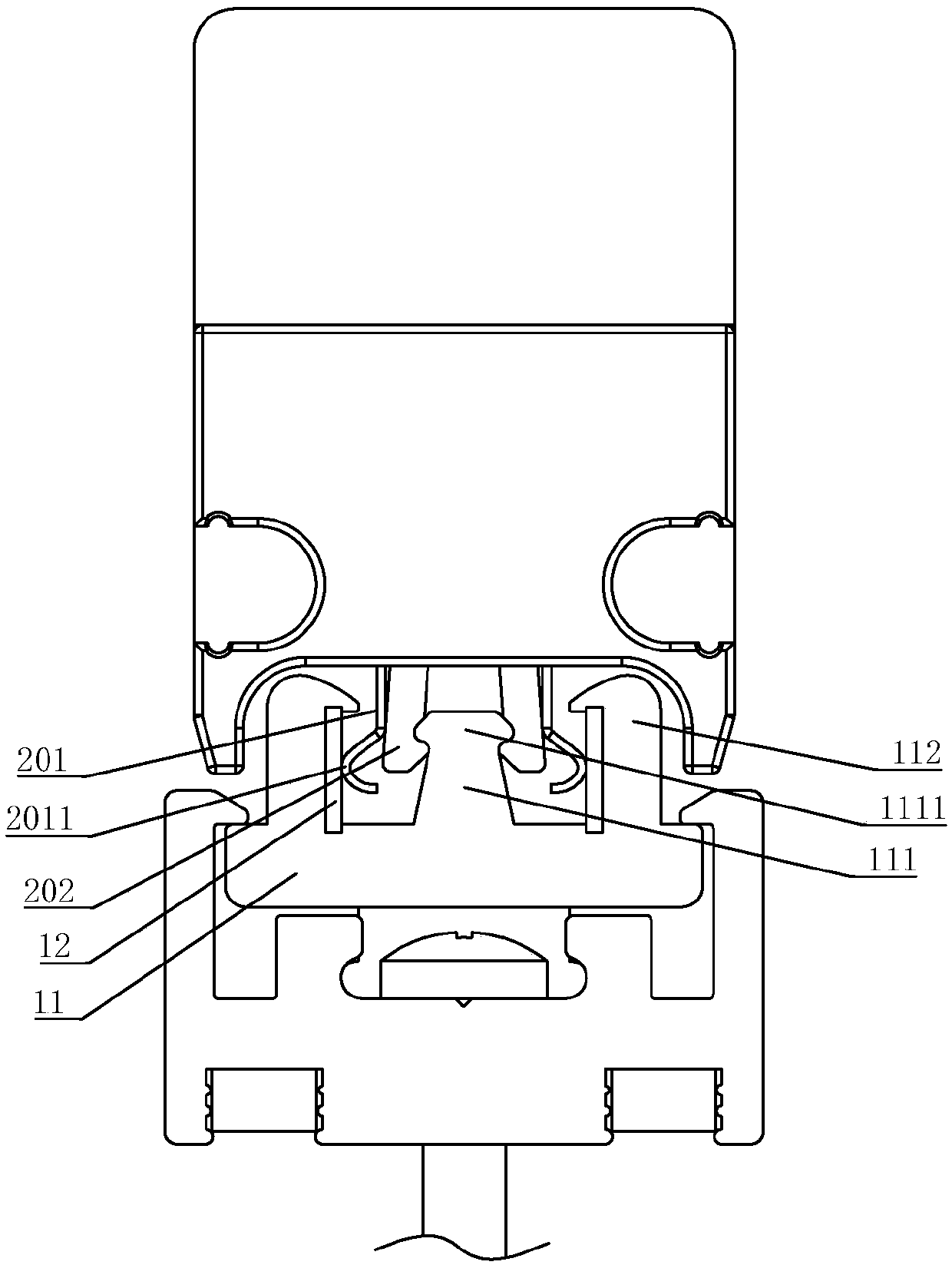

[0030] refer to Figure 1 to Figure 8 , a track light provided by the present invention includes a track part 1 and at least one lamp body module 2 installed on the track part 1, the track part 1 includes a guide rail part 11, and a track electrode 12 arranged on the guide rail part 11 , one end of the guide rail part 11 is provided with a power supply connection part 10 electrically connected to the track electrode 12 for supplying power to the guide rail part 11, and the guide rail part 11 is provided with an electrode isolation part 111 between the track electrodes 12, the electrode The isolation part 111 separates the track electrode 12 and increases the creepage distance, thereby improving the working voltage and safety of the track light. The end of the electrode isolation part 111 close to the lamp body module 2 is provided with a fastening part 1111, and the lamp body module 2 is provided with a connecting terminal 201 electrically connected to the track electrode 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com