Oil nozzle capable of automatically controlling pressure

An oil nozzle, automatic technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve the problems of inconvenience, oil control and management need to be strengthened, etc., to achieve the effect of controllable oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

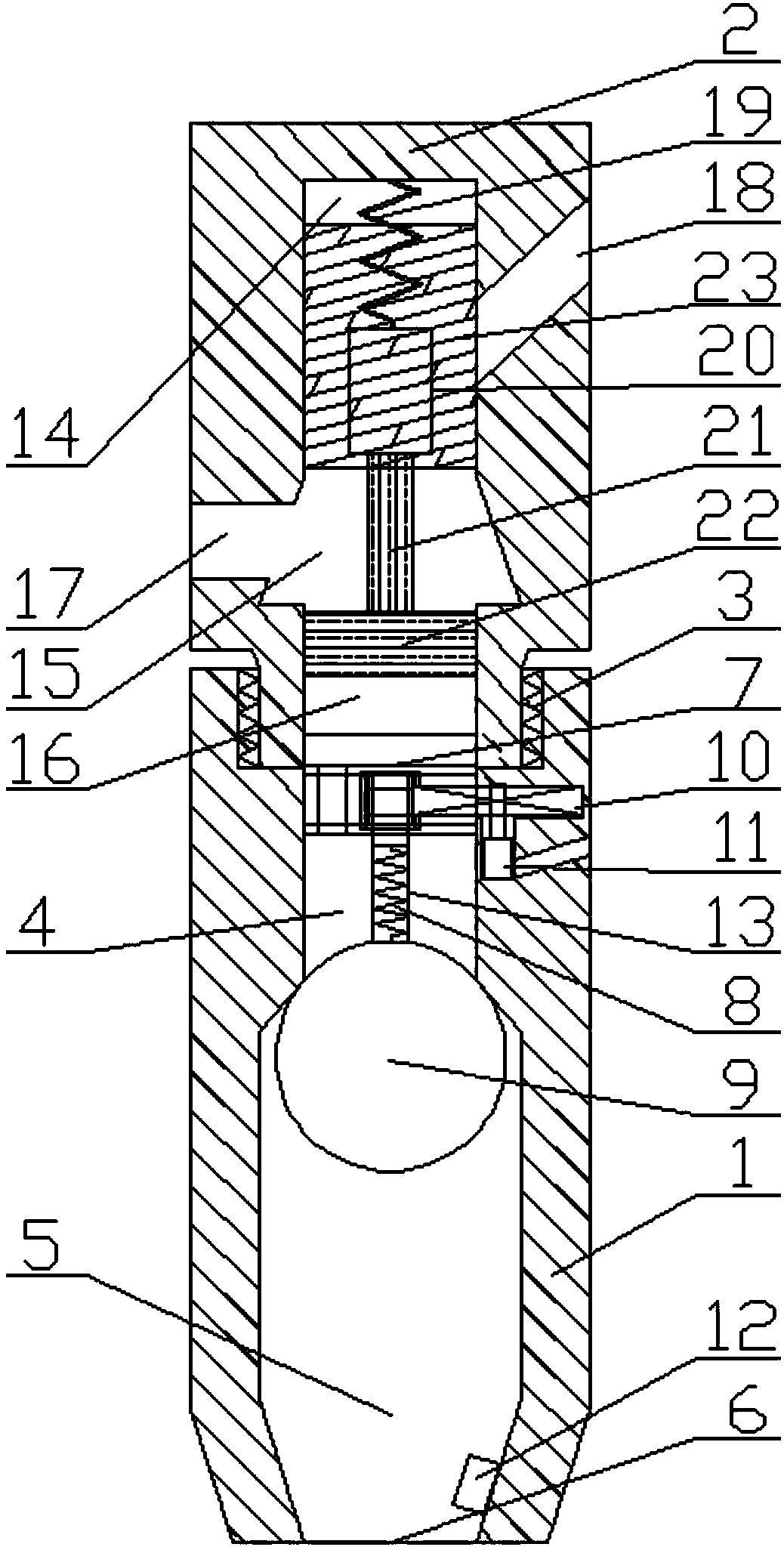

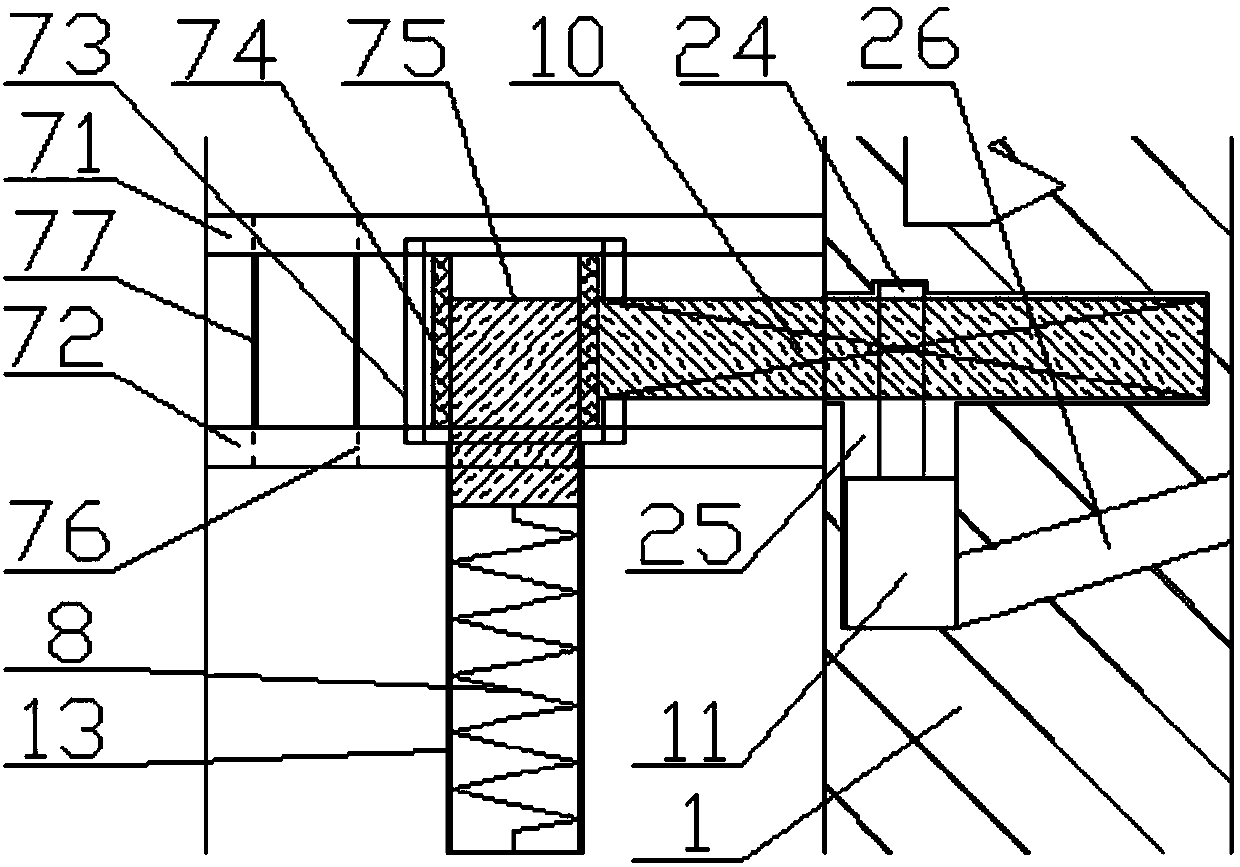

[0031] Such as figure 1 As shown, a fuel nozzle 1 that can automatically control the pressure is connected and fixed at the lower end of the fuel injector body 2 to form a fuel injector, wherein,

[0032] The injector body 2 is provided with a top chamber 14, an oil inlet chamber 15 and an oil passage 16 connected in sequence from top to bottom, and the top chamber 14 is provided with a coil 23 and an armature 20 surrounded by the coil 23, The side wall of the injector body 2 on the side of the coil 20 is provided with a power supply tank 18 for supplying power to the coil 23, and the upper end of the armature 20 is connected to the top of the top chamber 14 through a spring 19; It is shaped like a circular frustum that gradually widens downward, and the oil inlet chamber 15 communicates with the external fuel distribution pipe through the oil inlet pipe 17; the oil passage one 16 is provided with a switch plate 22 whose periphery is closely attached to the inner wall of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com