Medium-low carbon steel wire with excellent deformation performance and production method thereof

A technology of deformation performance and production method, which is applied in the field of metallurgy, can solve problems such as part failure, and achieve the effects of less surface defects, high spheroidization level, and improved grain size level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The medium-low carbon steel wire rod with excellent deformability in this embodiment is SWRCH22A, the main chemical composition and mass percentage are: C: 0.20%, Mn: 0.80%, P: 60ppm, N: 30ppm, S: 20ppm.

[0044] Taking Φ16mm wire rod as an example, the production method includes billet opening, rolling, and cooling processes. The specific process steps are as follows:

[0045] (1) Billet opening process: After the billet is billeted, the billet is finished, and the finished billet has a defect depth of 0.1mm.

[0046] (2) Rolling process: During the rolling process, the amount of steel passing through the rolls is guaranteed to be 900 tons, and the wear in the rolling channel is strictly controlled.

[0047] (3) Cooling process: the surface cooling rate is 6°C / s.

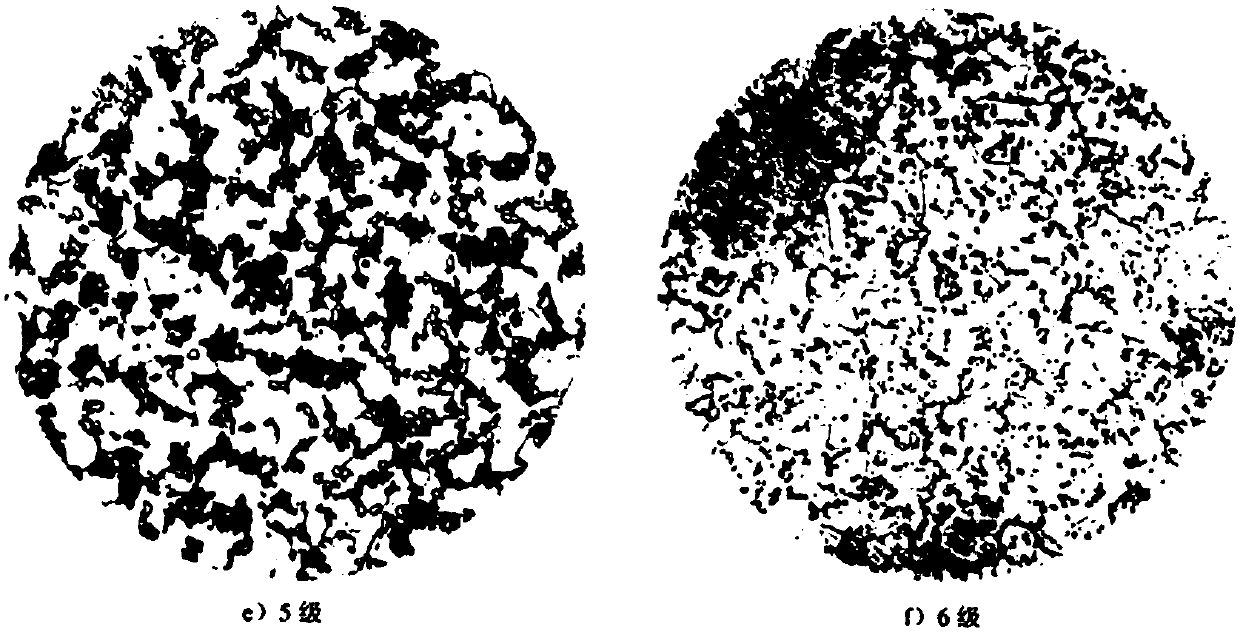

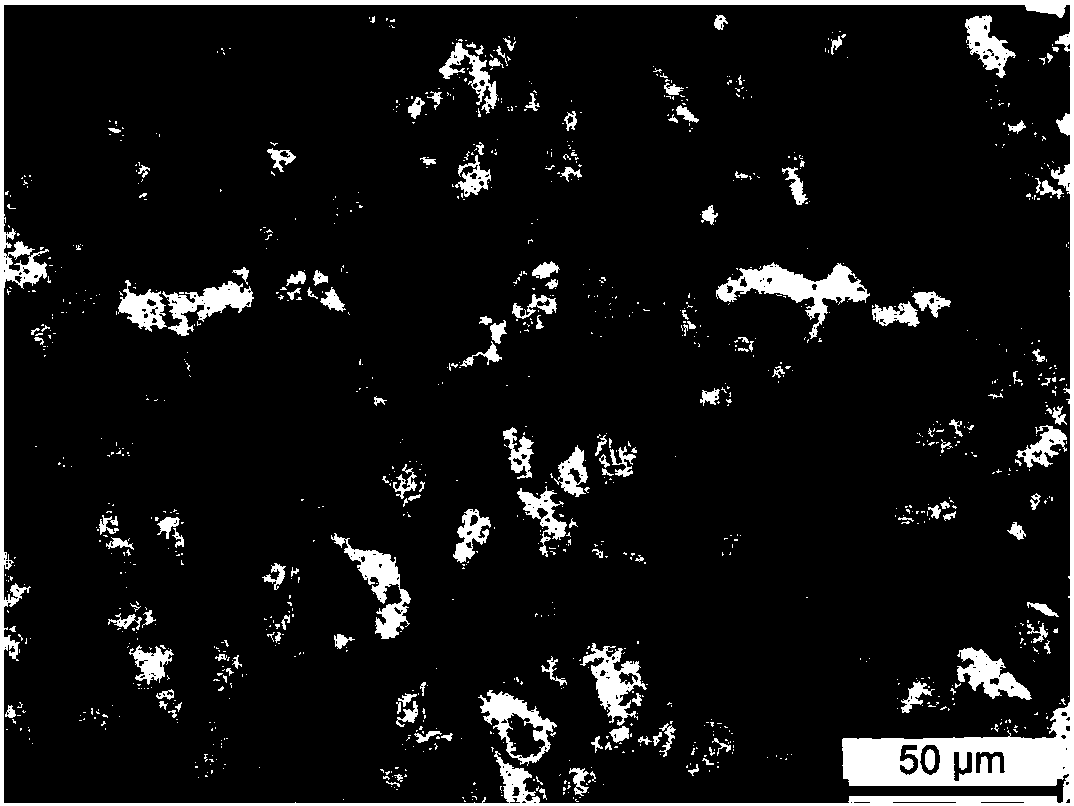

[0048] The actual detected grain size is grade 9, the interlamellar spacing of pearlite is 1.5 μm, the depth of the detected surface defects is less than 50 μm, and the length does not exceed 2mm; the metal...

Embodiment 2

[0051] The medium-low carbon steel wire rod with excellent deformability in this embodiment is SWRCH18A, the main chemical composition and mass percentage are: C: 0.16%, Mn: 0.40%, P: 45ppm, N: 20ppm, S: 15ppm.

[0052] Taking Φ10mm wire rod as an example, the production method includes billet opening, rolling, and cooling processes. The specific process steps are as follows:

[0053] (1) Billet opening process: After the billet is billeted, the billet is finished, and the finished billet has a defect depth of 0.15mm.

[0054] (2) Rolling process: During the rolling process, the amount of steel passing through the rolls is guaranteed to be 980 tons, and the wear in the rolling channel is strictly controlled.

[0055] (3) Cooling process: the surface cooling rate is 5°C / s.

[0056] The actual detected grain size is 8.5, the interlamellar spacing of pearlite is 2μm, the depth of the detected surface defects is less than 50μm, and the length does not exceed 2mm; the metallograph...

Embodiment 3

[0059] The medium and low carbon steel wire with excellent deformation performance in this example is SWRCH25k, the main chemical composition and mass percentage are: C: 0.25%, Mn: 0.70%, Si: 0.15%, P: 55ppm, N: 40ppm, S : 25ppm.

[0060] Taking Φ20mm wire rod as an example, the production method includes blanking, rolling, and cooling processes. The specific process steps are as follows:

[0061] (1) Billet opening process: After the billet is billeted, the billet is finished, and the finished billet has a defect depth of 0.05mm.

[0062] (2) Rolling process: During the rolling process, the amount of steel passing through the rolls is guaranteed to be 800 tons, and the wear in the rolling channel is strictly controlled.

[0063] (3) Cooling process: the surface cooling rate is 8°C / s.

[0064] The actual detected grain size is 10 grades, the interlamellar spacing of pearlite is 1.0μm, the depth of the detected surface defects is less than 50μm, and the length does not exceed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com