Method for controlling reduction rate of iron ore in converter

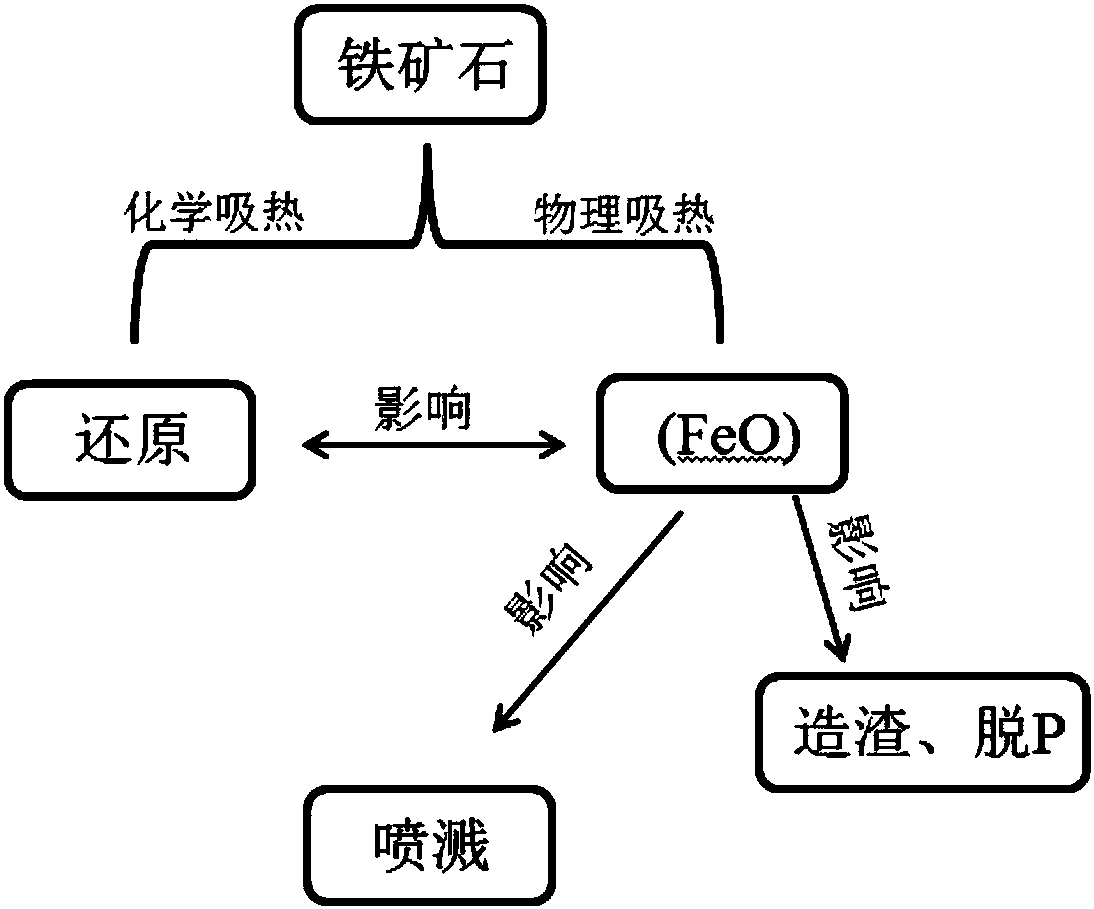

A technology of iron ore and converter, which is applied in the field of controlling the reduction rate of iron ore in the converter, which can solve problems such as smoke, splashing, and active carbon-oxygen reaction, and achieve the effects of preventing splashing and reducing melting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for controlling the reduction rate of iron ore in the converter in this embodiment is to add molten iron with a temperature of 1320°C in a 120t converter, and after the lance is lowered and ignited and blown, add 50% of the total slagging material with a particle size of 5.0 to 20.0 mm (equivalent diameter) of iron ore, take slag sample 1 after blowing for 1 minute, return to the furnace body and continue blowing, and add iron with a mass of 300kg and a particle size of 20.0 to 50.0mm after blowing for 7 minutes For ore, after blowing for 30s, take the slag sample 2.

[0029] The whole process of blowing is smooth without splashing. Through the detection results of slag sample 1 and the conversion of the pre-feeding, the reduction rate of iron ore added in the early stage is 44%, and the detection results of slag sample 2 and the conversion of mid-term feeding, the reduction rate of iron ore added in the mid-term is 63%. .

Embodiment 2

[0031] A method for controlling the reduction rate of iron ore in the converter in this embodiment is to add molten iron with a temperature of 1300°C in a 120t converter, and after the lance is lowered and ignited and blown, add 60% of the total slagging material with a particle size of 5.0 to 20.0 mm (equivalent diameter) of iron ore, after blowing for 1 minute, turn the furnace back to take slag sample 3, return to the furnace body and continue blowing, and add 200kg of iron with a particle size of 20.0 to 50.0mm after blowing for 7 minutes For ore, after blowing for 30s, take the slag sample by turning back the furnace 4.

[0032] The whole process of blowing is smooth without splashing. Through the test results of slag sample 3 and the conversion of the early feeding, it is concluded that the reduction rate of iron ore added in the early stage is 37%. The detection results of slag sample 4 and the conversion of mid-term feeding show that the reduction rate of iron ore adde...

Embodiment 3

[0034] A method for controlling the reduction rate of iron ore in the converter in this embodiment is to add molten iron with a temperature of 1450°C in a 120t converter, and after the lance is lowered and ignited and blown, add 70% of the total slagging material with a particle size of 5.0 to 20.0 mm (equivalent diameter) of iron ore, take the slag sample 5 after blowing for 1 minute, return to the furnace body and continue blowing, and add iron with a mass of 100 kg and a particle size of 20.0 to 50.0 mm after blowing for 8 minutes For ore, take the slag sample after blowing for 30 seconds.

[0035] The whole process of blowing is smooth without splashing. Through the detection results of slag sample 5 and the conversion of the early feeding, the reduction rate of iron ore added in the early stage is 42%, and the detection results of slag sample 6 and the conversion of mid-term feeding show that the reduction rate of iron ore added in the mid-term is 65%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com