Anaerobic ammonium oxidation granular sludge cultivation method and cultivation device

An anaerobic ammonia oxidation and granular sludge technology, applied in anaerobic digestion treatment and other directions, can solve the problems of high operating cost and energy consumption, low biomass enrichment capacity, large amount of sludge production, etc. The effect of reduced sludge loss and good settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

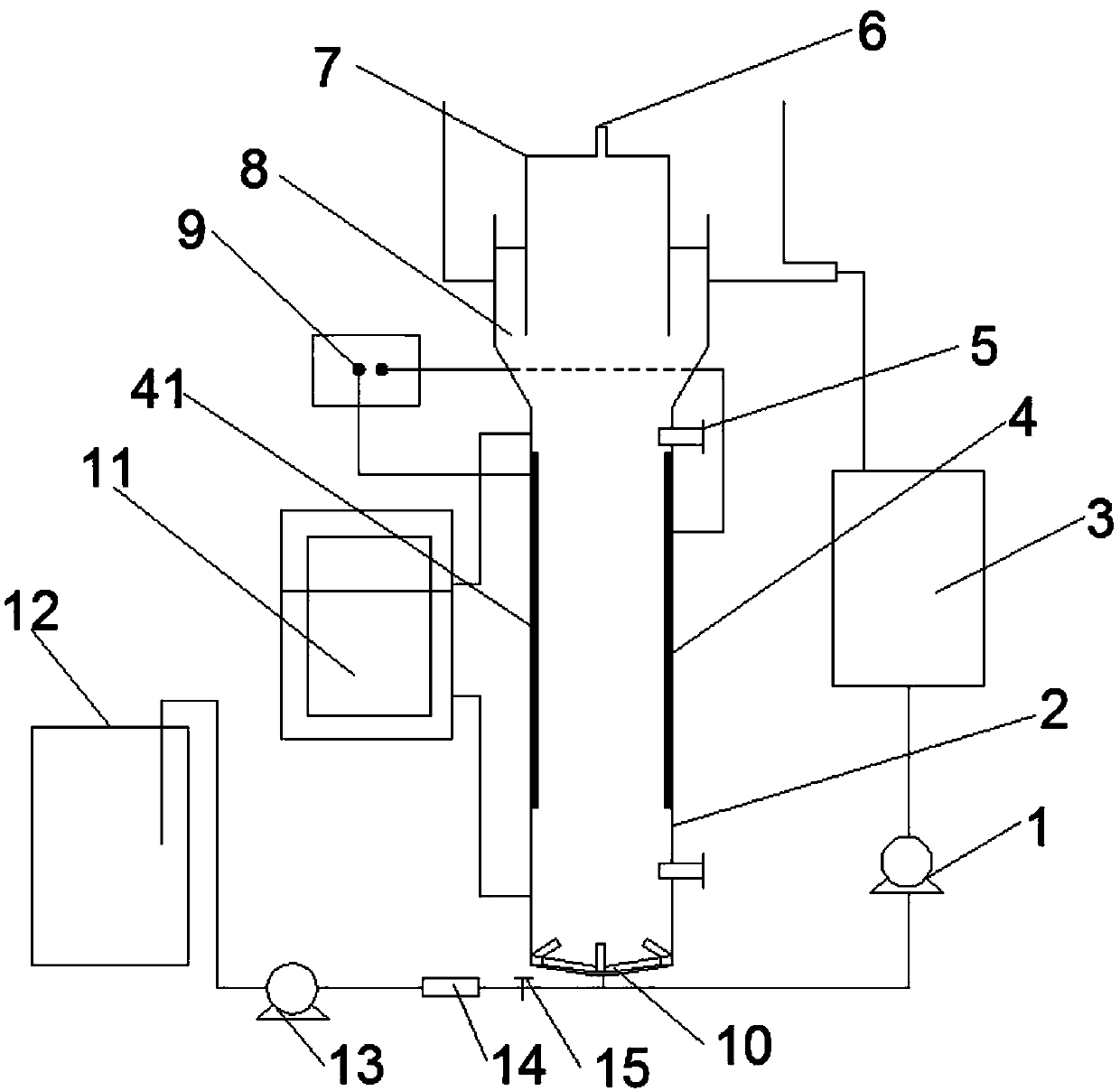

[0035] A method for cultivating anaerobic ammonium oxidation granular sludge, comprising the following steps:

[0036] Step 1: Fill the activated sludge into the reactor 2 equipped with the three-phase separator 7, form an activated sludge area at the bottom of the reactor 2, adjust the temperature through the constant temperature device 11, and control the temperature in the reactor 2 between 30°C ;

[0037] Step 2: Put wastewater with an oxygen concentration of 0.1mg / L and a pH value of 7.2 into the reactor 2 through a peristaltic pump at an ascending flow rate of 1m / h for reaction, and add an appropriate amount of trace element substances to maintain microbial growth in the wastewater and inorganic carbon source, the concentration of ammonia nitrogen in the waste water is 500mg / L, the ratio of the amount of ammonia nitrogen to nitrous nitrogen is 0.8:1, and the water retention time of reactor 2 is 10h;

[0038] Step 3: Keep the influent concentration of ammonia nitrogen an...

Embodiment 2

[0046] A method for cultivating anaerobic ammonium oxidation granular sludge, comprising the following steps:

[0047] Step 1: Fill the activated sludge into the reactor 2 equipped with the three-phase separator 7, form an activated sludge area at the bottom of the reactor 2, adjust the temperature through the constant temperature device 11, and control the temperature in the reactor 2 at 30-35°C between;

[0048] Step 2: Put wastewater with an oxygen concentration of 1 mg / L and a pH value of 7.6 into the reactor 2 through a peristaltic pump at an ascending flow rate of 3 m / h for reaction, and add an appropriate amount of trace element substances and Inorganic carbon source, the concentration of ammonia nitrogen in the waste water is 1000mg / L, the ratio of the amount of ammonia nitrogen to nitrite nitrogen is 0.9:1, and the water retention time of reactor 2 is 12h;

[0049] Step 3: Keep the influent concentration of ammonia nitrogen and nitrite nitrogen in reactor 2 stable, t...

Embodiment 3

[0057] A method for cultivating anaerobic ammonium oxidation granular sludge, comprising the following steps:

[0058] Step 1: Fill the activated sludge into the reactor 2 equipped with the three-phase separator 7, form an activated sludge area at the bottom of the reactor 2, adjust the temperature through the constant temperature device 11, and control the temperature in the reactor 2 at 30-35°C between;

[0059] Step 2: Put wastewater with an oxygen concentration of 0.2mg / L and a pH value of 7.3 into the reactor 2 through a peristaltic pump at an ascending flow rate of 2m / h for reaction, and add an appropriate amount of trace element substances to maintain microbial growth in the wastewater and inorganic carbon source, the concentration of ammonia nitrogen in the waste water is 700mg / L, the ratio of the amount of ammonia nitrogen to nitrous nitrogen is 1:1, and the water retention time of reactor 2 is 10.5h;

[0060] Step 3: Keep the influent concentration of ammonia nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com