Irregular hardware block pressing sleeve mechanism capable of precisely adjusting position

An irregular hardware block technology, applied in the field of irregular hardware block pressing mechanism, can solve the problems of manual installation, no automatic installation of center sleeve, hardware block fixing trouble, etc., and achieves firm clamping and fixing, simple structure, and effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

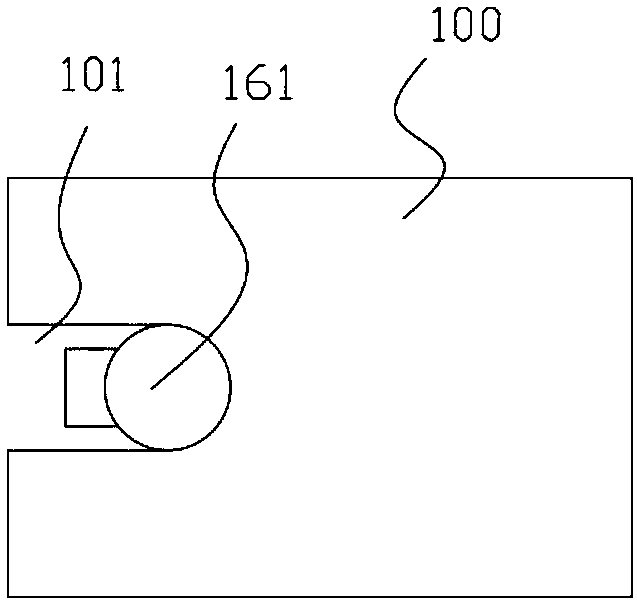

[0016] Example: see Figure 1 to Figure 2 As shown, an irregular metal block press-fitting mechanism whose position can be precisely adjusted includes a frame 10, an upper support frame 11 is fixed on the top surface of the top plate of the frame 10, and the middle top surface of the top plate of the frame 10 is fixed There is an installation groove 12, the elastic protection block 13 is nested in the installation groove 12, the bottom surface of the elastic protection block 13 is fixed on the bottom surface of the installation groove 12, and the workpiece 100 to be processed is inserted and clamped in the elastic protection block 13 In the main groove 131 that the top surface has, the middle part of the top plate of the upper support frame 11 has a transverse through groove 111, and the top surface of the top plate of the upper support frame 11 on both sides of the transverse through groove 111 is fixed with a support plate 112, and the transverse screw rod The two ends of 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com