Waste compression treatment device

A technology for compressing and processing waste, applied in the field of machinery, can solve the problems of waste liquid cleaning, cost, economic benefit, lack of manual waste compressing processor, etc. maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

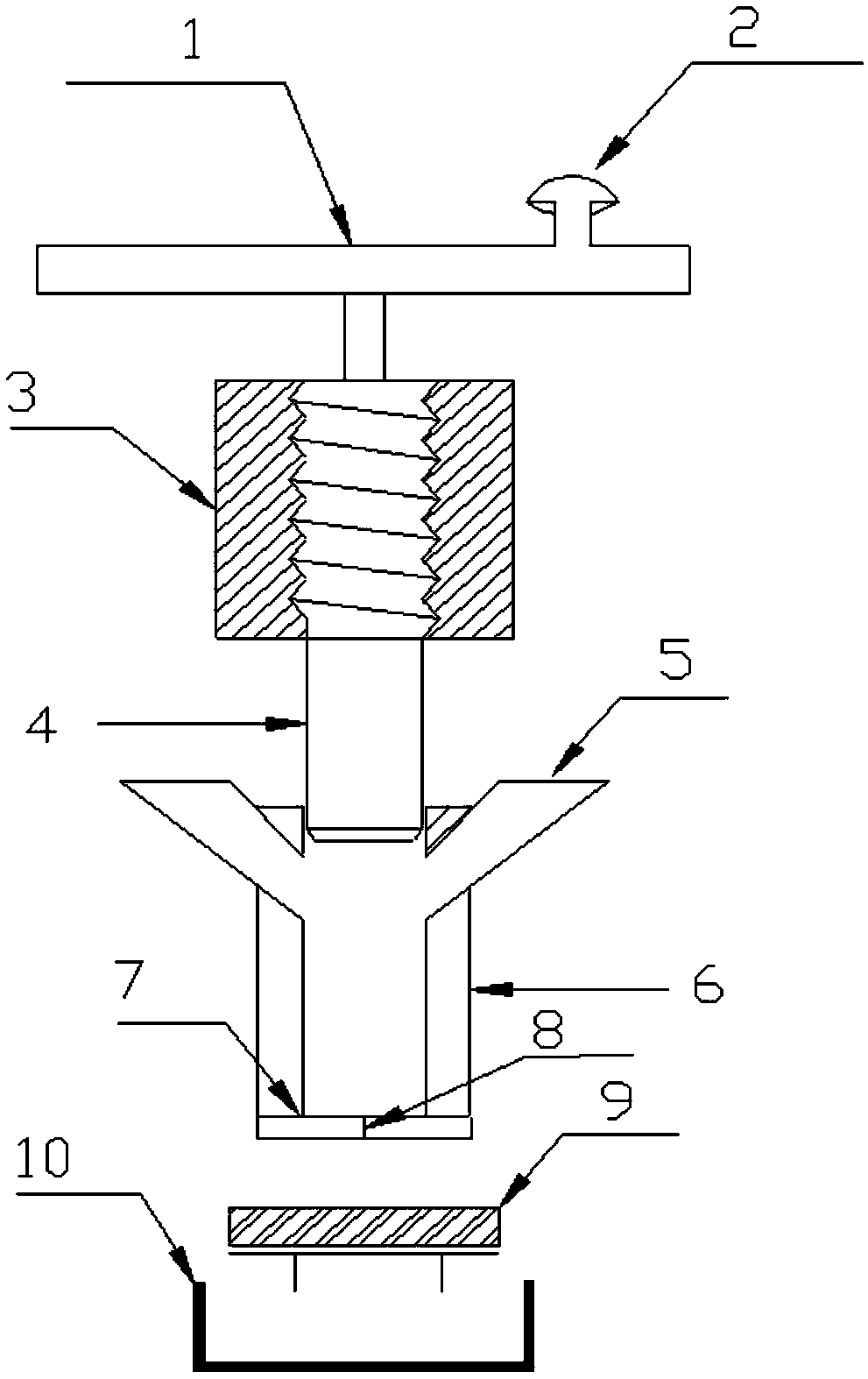

[0024] see figure 1 , the present invention includes a frame 3, the frame 3 is provided with a shaft 4, the shaft 4 is provided with an external thread, the frame 3 is provided with an internal thread that cooperates with the external thread, and the top surface of the shaft 4 is connected with a turntable 1, The top of the turntable 1 is provided with a crank 2, the lower part of the frame 3 is provided with a compression chamber 6, the shaft 4 can extend into the compression chamber 6, the axial surface of the shaft 4 is attached to the inner surface of the compression chamber 6, and the side of the compression chamber 6 is provided with The waste input port 5 and the bottom of the compression chamber 6 are provided with a waste outlet 7. When collecting waste, the shaft 4 is placed on the top of the compression chamber 6; A liquid hole, a waste liquid collector 10 is arranged below the waste outlet 7 and a filter packaging device 9 is provided below the filter packaging dev...

Embodiment 2

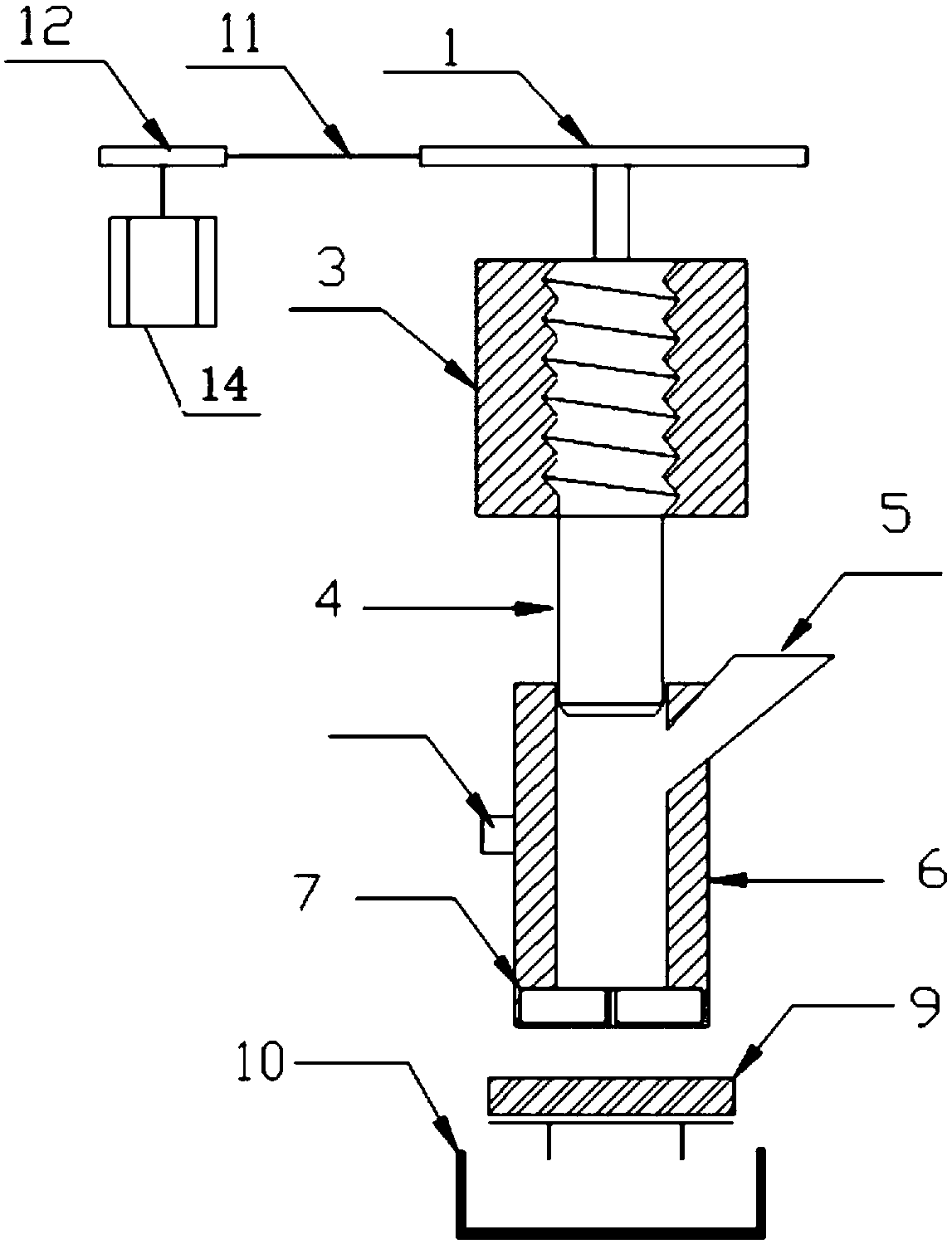

[0028] see figure 2 , the present invention comprises a frame 3, the frame 3 is provided with a shaft 4, the shaft 4 is provided with an external thread, the frame 3 is provided with an internal thread that cooperates with the external thread, and the bottom of the frame 3 is provided with a compression chamber 6, The shaft 4 can extend into the compression chamber 6, and the axial surface of the shaft 4 is attached to the inner surface of the compression chamber 6. The side of the compression chamber 6 is provided with a waste input port 5, and the bottom of the compression chamber 6 is provided with a waste outlet 7. When collecting waste, the shaft 4 is placed on the top of the compression chamber 6; when the waste is compressed, the shaft 4 can be in contact with the waste outlet 7, and a number of seepage holes begin to appear on the waste outlet 7, and a filter packing device 9 is provided below the waste outlet 7. The waste liquid collector 10, the top surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com