Movable flash welding and heat treatment technology for 60kg/mU75V+U75VG steel rail

A rail and process technology, applied in the field of 60kg/mU75V+U75VG rail mobile flash welding and heat treatment technology, can solve the problems of non-compliance and unsatisfaction in the drop weight inspection of joints, and achieve the effects of less internal defects, improved quality and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

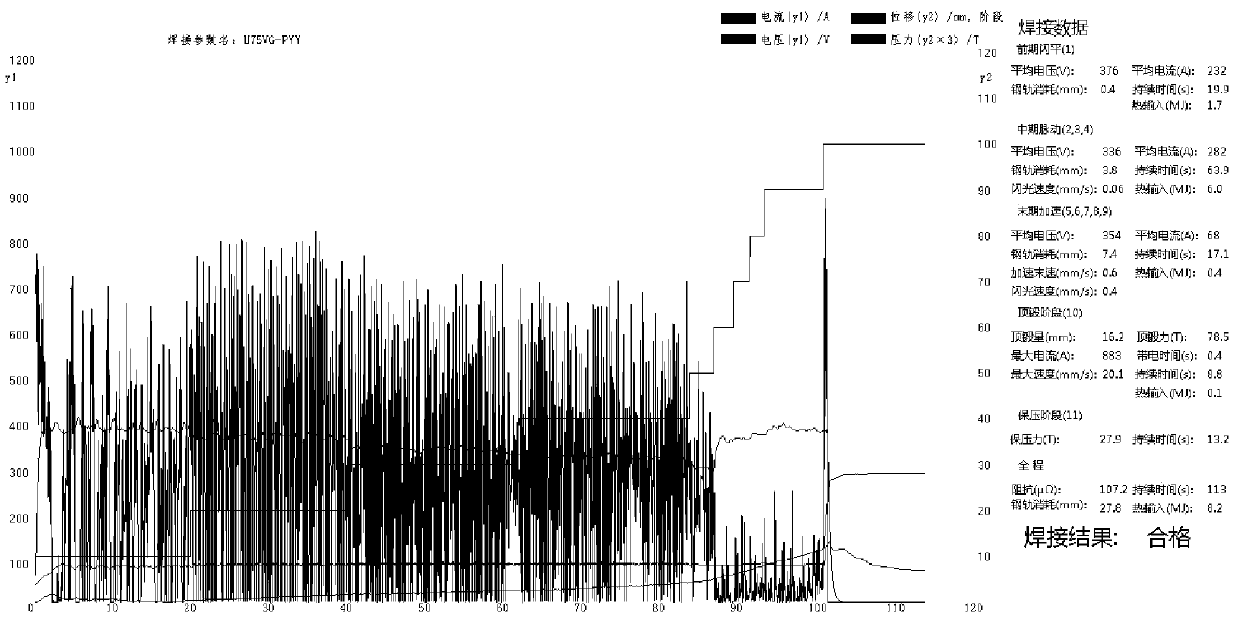

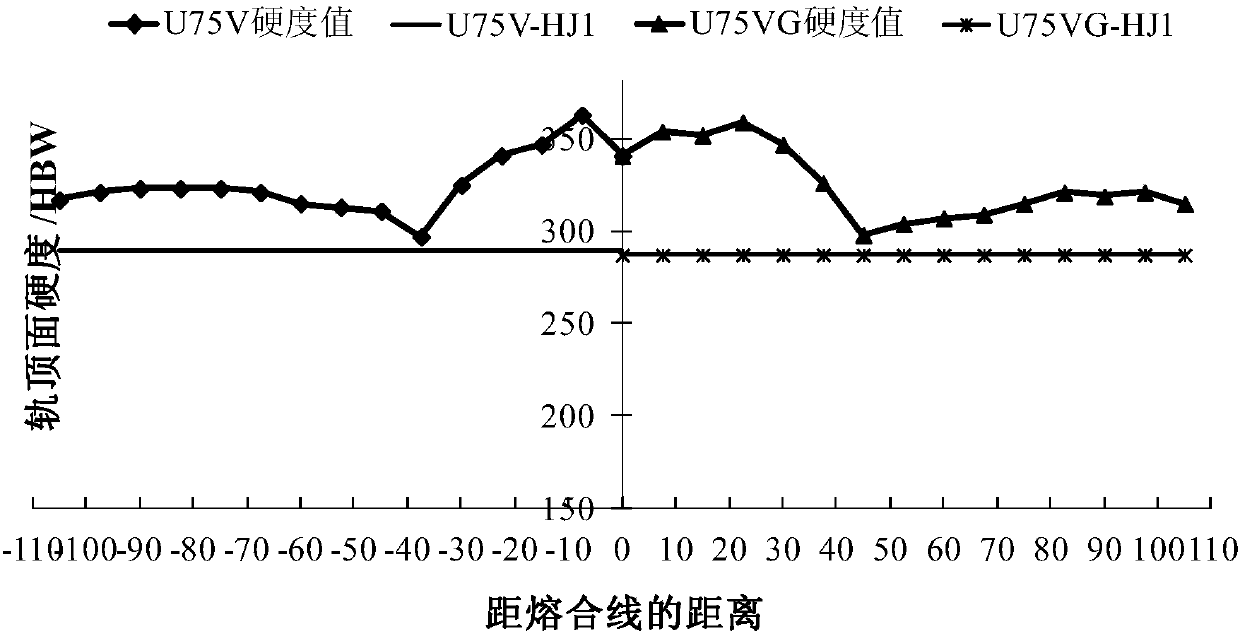

[0024] When the U75V+U75VG rail is welded by a mobile rail flash welding machine, the welding heat input in the first stage of flash flattening is 1.7MJ, the rail consumption is 0.4mm, and the duration is 19.9s. The welding heat input in the second stage of pulsation is 6.0MJ, the rail consumption is 3.8mm, and the duration is 63.9s. In the third stage of accelerated sintering, the welding heat input is 0.4MJ, the rail consumption is 7.4mm, and the duration is 17.1s. The welding heat input of the fourth stage of upsetting is 0.10MJ, the amount of upsetting is 16.2mm, the time of live upsetting is 0.4s, and the duration is 8.8s. The holding pressure of the fifth stage of holding pressure is 27.9T, and the duration is 13.2s. Control the total welding heat input to 8.2MJ, the total rail consumption to 27.8mm and the total welding duration to 113s to achieve the purpose of controlling the welding quality.

[0025] When the joint temperature after upsetting and pushing is natural...

Embodiment 2

[0027] When the U75V+U75VG rail is welded by a mobile rail flash welding machine, the welding heat input in the first stage of flash flattening is 1.6MJ, the rail consumption is 1.5mm, and the duration is 19.9s. The welding heat input in the second stage of pulsation is 6.2MJ, the rail consumption is 6.2mm, and the duration is 64s. In the third stage of accelerated sintering, the welding heat input is 0.3MJ, the rail consumption is 8.0mm, and the duration is 17.1s. The welding heat input of the fourth stage of upsetting is 0.10MJ, the upsetting amount is 16.4mm, the live upsetting time is 0.4s, and the duration is 6.8s. The holding pressure of the fifth stage of holding pressure is 27.9T, and the duration is 13.2s. Control the total welding heat input to 8.2MJ, the total rail consumption to 32.1mm and the total welding duration to 113s to achieve the purpose of controlling the welding quality.

[0028] When the joint temperature after upsetting and pushing is naturally coole...

Embodiment 3

[0030]When the U75V+U75VG rail is welded by a mobile rail flash welding machine, the welding heat input in the first stage of flash flattening is 1.6MJ, the rail consumption is 0.6mm, and the duration is 19.9s. The welding heat input in the second stage of pulsation is 6.0MJ, the rail consumption is 6.8mm, and the duration is 63.9s. In the third stage of accelerated sintering, the welding heat input is 0.3MJ, the rail consumption is 7.6mm, and the duration is 16.3s. The welding heat input of the fourth stage of upsetting is 0.10MJ, the upsetting amount is 16.4mm, the live upsetting time is 0.4s, and the duration is 7.4s. The holding pressure of the fifth stage of holding pressure is 27.0T, and the duration is 13.2s. Control the total welding heat input to 8.1MJ, the total rail consumption to 31.4mm and the total welding duration to 113s to achieve the purpose of controlling the welding quality.

[0031] When the joint temperature after upsetting and pushing is naturally cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com