Automatic stamping system and method applicable to stainless steel cylinder parts of different sizes

A technology of cylindrical parts and stainless steel, which is applied in the field of automatic stamping systems, can solve the problems of complex process and low production efficiency of non-standard stainless steel cylinders, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

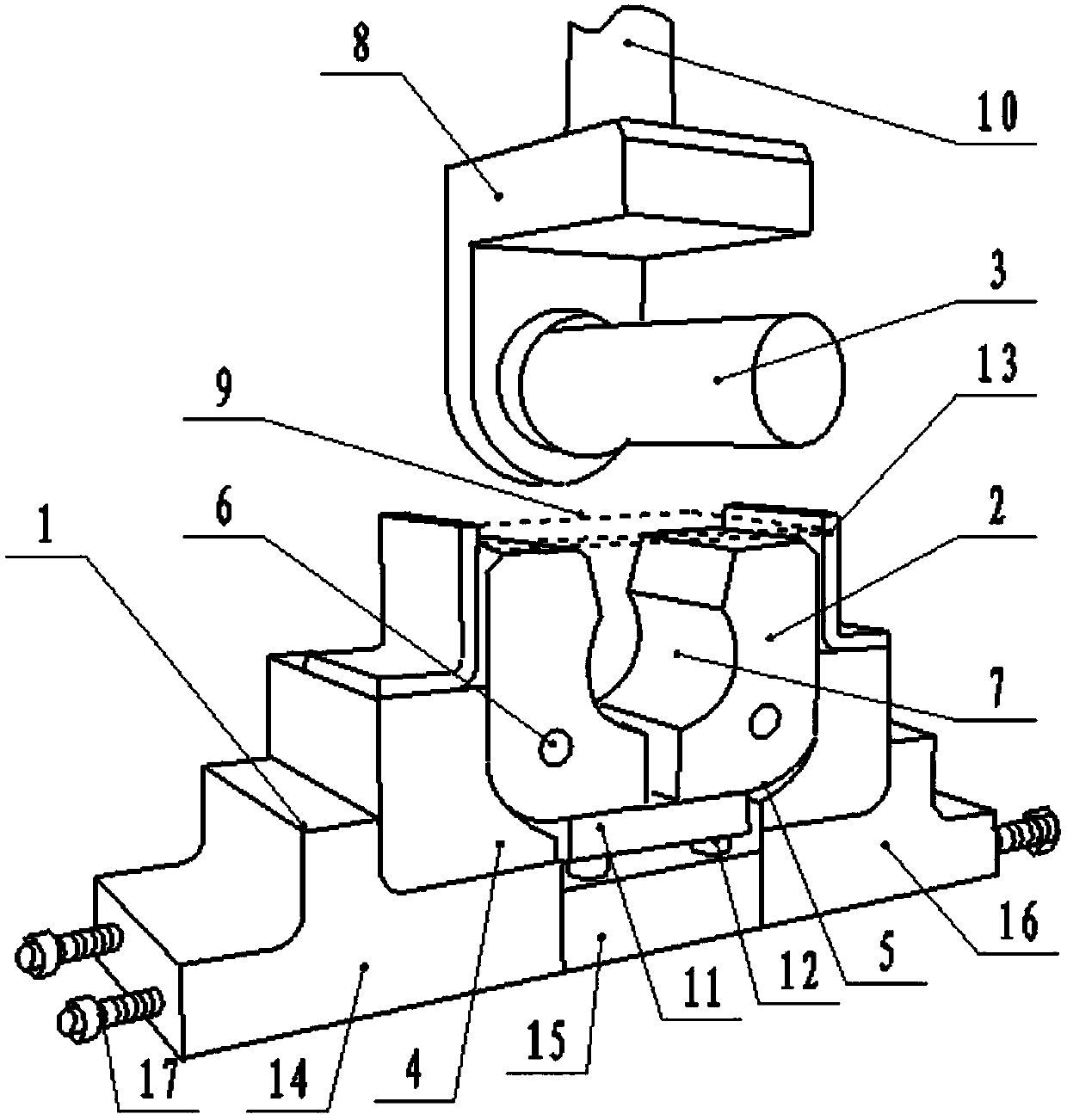

[0036] Such as figure 1 As shown, the present invention is an automatic stamping system suitable for stainless steel cylinders of different sizes, including a stamping base 1, a stamping female module 2 and a stamping male die rod 3, and the stamping base 1 includes a left stamping base 14, a middle stamping base 15 and The right stamping base 16, the left stamping base 14 and the right stamping base 16 are respectively connected with the middle stamping base 15 through the adjusting screw 17;

[0037] The middle stamping base 15 of the stamping base 1 is symmetrically provided with two stamping limit blocks 4, and the inner surfaces of the left stamping base 14 and the right stamping base 16 are all provided with a limiting arc surface 5, and the two stamping The female module 2 is correspondingly arranged on the limiting arc surface 5 of the left stamping base 14 and the right stamping base 16 through the limiting shaft 6; camber 7;

[0038] The stamping male mold rod 3 is...

Embodiment 2

[0052] Such as figure 1 As shown, the present invention is an automatic stamping method applicable to stainless steel cylindrical parts of different sizes, comprising steps:

[0053] Step 1) Adjust the distance between the left stamping base (14) and the middle stamping base (15); the distance between the right stamping base (16) and the middle stamping base (15) by adjusting the screw rod (17);

[0054] Step 2) After the size adjustment of the stamping base (1) is completed, place the cut stamping plate (9) between the two L-shaped stamping plates (13) stoppers;

[0055] Step 3) Then, the punching bed drives the punching arm (10) to punch downwards, and the punching arm (10) drives the punching male die rod (3) to punch the punching plate (9);

[0056] Step 4) Stamping the male mold rod (3) by inserting the stamping plate (9) into the two stamping female modules (2) to form a cylindrical mold, and under the stamping action of the stamping male mold rod (3), the stamping fema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com