Oil filter for eliminating lubricating oil film

A technology of oil filter and paint, which is applied in the direction of filtration and separation, filtration circuit, separation method, etc., can solve the problems of economic waste, reduce the purification degree of particle impurities, impurity filtration, etc., so as to prolong the service life and restore the physical and chemical Indicators, the effect of avoiding parts sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

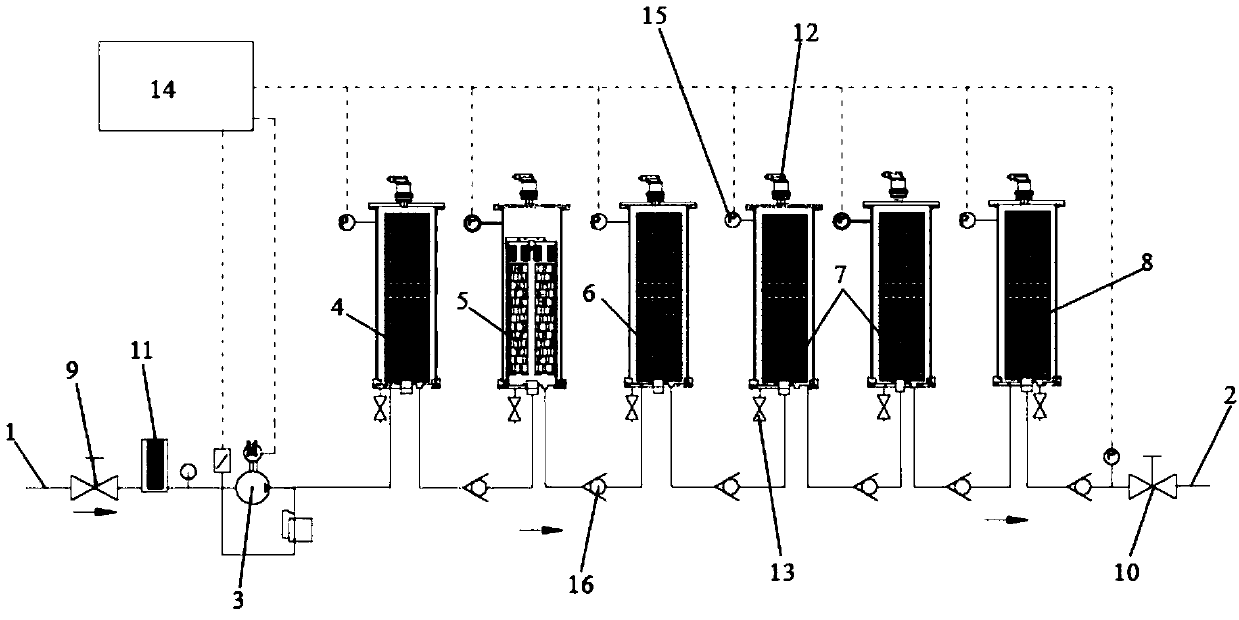

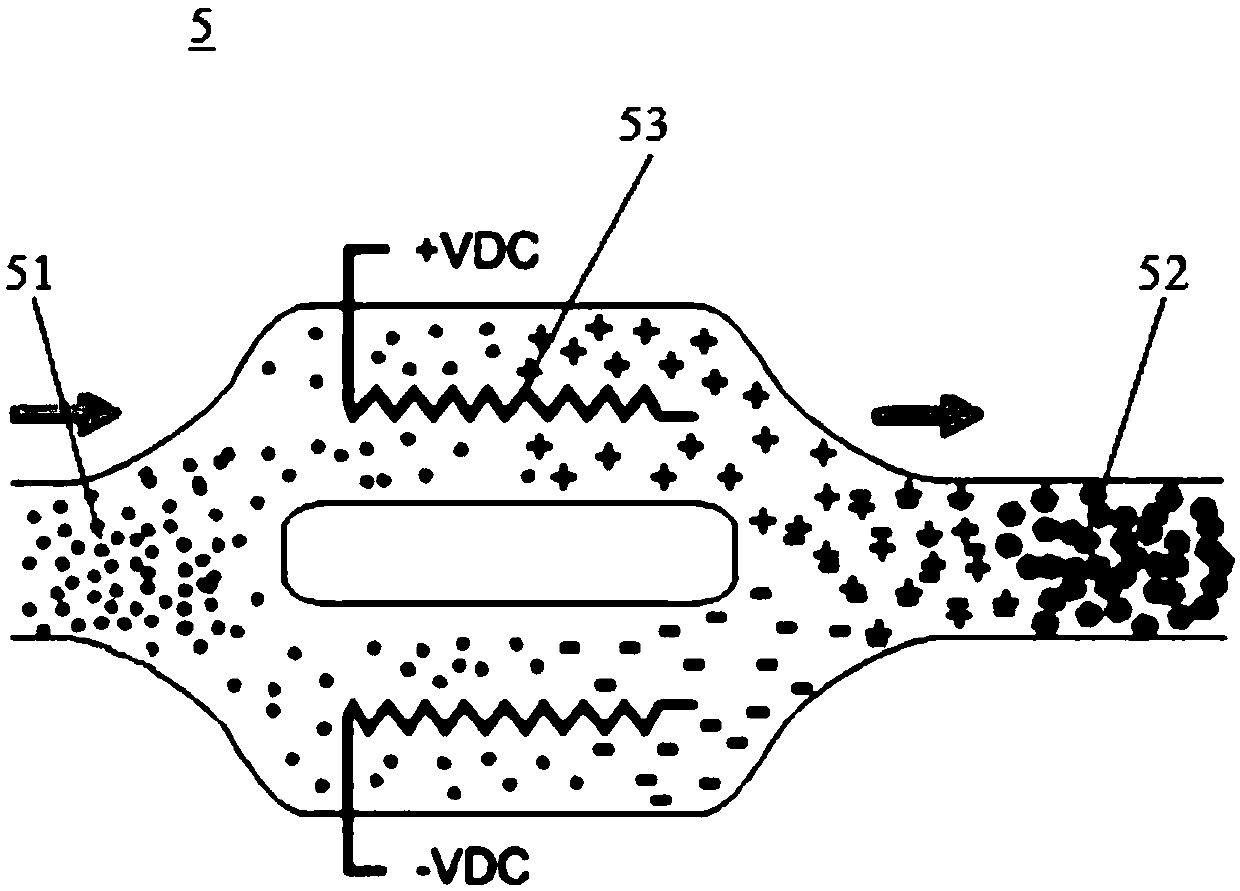

[0026] Please refer to Figure 1-Figure 2 , the present embodiment is an oil filter for removing lubricating paint film, which includes an oil inlet pipeline 1, an oil outlet pipeline 2 and an oil pump 3 arranged on the oil inlet pipeline 1, between the oil inlet pipeline 1 and the oil outlet pipeline 2 A first pre-filter 4 , a charging mixer 5 , a second pre-filter 6 , an exchange resin filter unit 7 and a protection filter 8 are sequentially arranged in between.

[0027] Between the first pre-filter 4 and the charging mixer 5, between the charging mixer 5 and the second pre-filter 6, between the second pre-filter 6 and the exchange resin filter unit 7, between the exchange resin filter unit 7 and the protection A one-way valve 16 is arranged on the communication pipe between the filters 8 and the interior of the exchange resin filter unit 7 to prevent backflow, guarantee the normal operation of the oil filter unit, and improve its safety.

[0028] The fluid passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com