Blockage preventive device of tobacco slicing machine

A slicing machine and anti-blocking technology, which is applied in the fields of tobacco, tobacco processing, metal processing, etc., can solve the problems of lack of blocking detection and alarm devices, affecting the production efficiency of enterprises, and cutting off materials in the production line, so as to improve production continuity and prevent The effect of material breaking and reducing the number of blocking times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

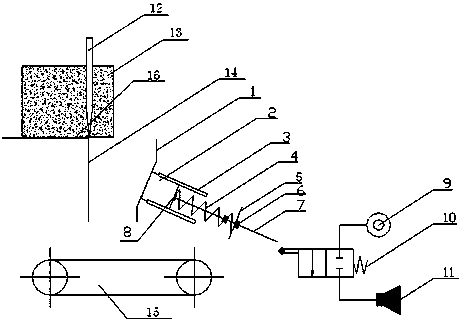

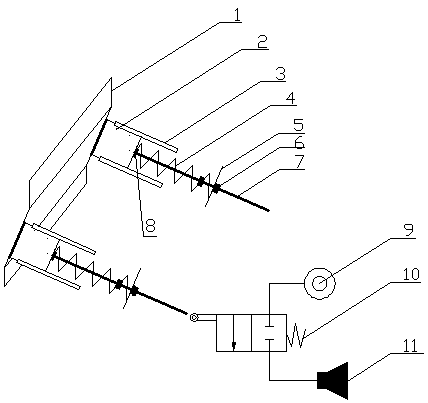

[0022] An anti-blocking material device for a tobacco slicer, comprising a cutter 12, a workbench 16, a downstream machine 15 and a baffle 14, the cutter 12 is located above the workbench 16, and the downstream machine 15 is located on the baffle 14, the baffle plate 14 is fixedly arranged below the workbench 16, and also includes a material guide plate 1, a reset mechanism and an alarm mechanism, the material guide plate 1 is located on the right side of the baffle plate 14, and the The gap between the material guide plate 1 and the baffle plate 14 only allows cigarette packs 13 whose size is smaller than or equal to the qualified standard to pass through. The material guide plate 1 is elastical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com