Upward-inlet-type air suction distributor for compressor condensing unit

A technology for a condensing unit and a compressor, which is applied in the field of compressors, can solve the problems of affecting the quality of the compressor, high gas pressure, easy oil intake, etc., and achieves the effects of simple structure, low cost and ingenious conception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

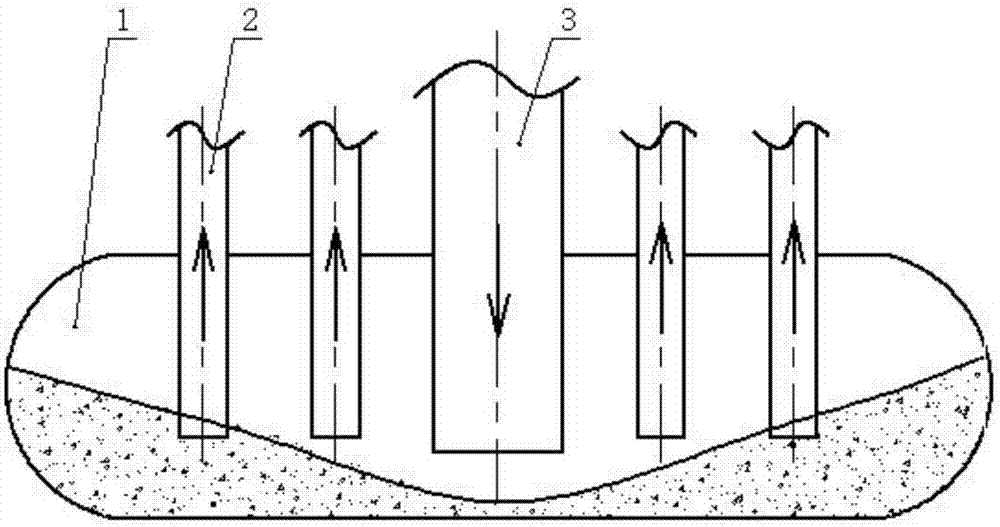

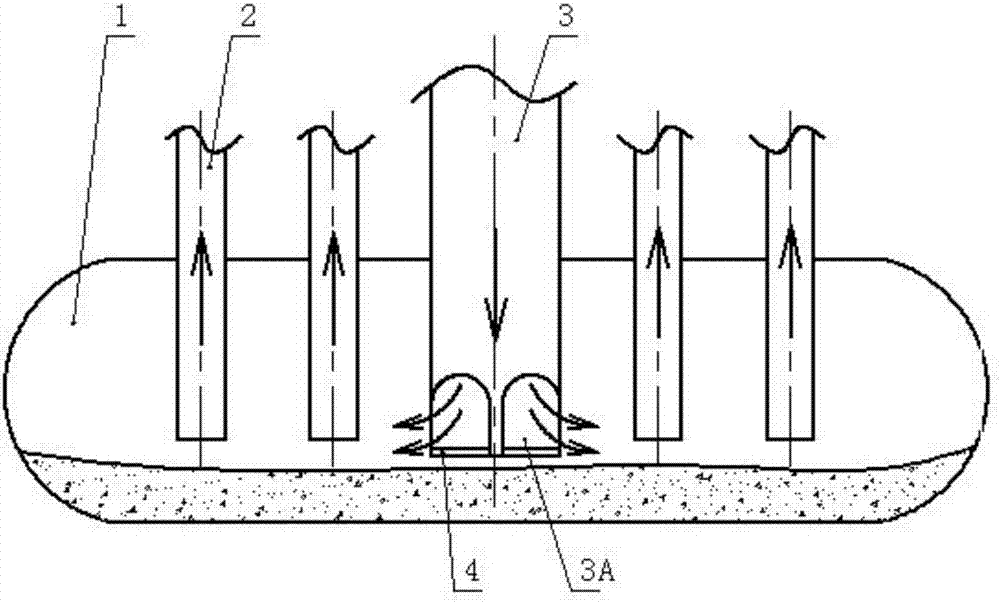

[0014] An upward suction distributor of a compressor condensing unit, such as figure 2 As shown, it includes a suction manifold 1, a branch pipe 2 and a return air manifold 3. The upper part of the suction manifold is vertically connected to the return air manifold, and the suction manifolds on the left and right sides of the return air manifold are vertical A plurality of branch pipes are connected and installed at intervals.

[0015] The innovation point of the present invention is:

[0016] The structure of the air return main pipe is as follows: the side wall of the bottom end of the air return main pipe embedded in the suction manifold is uniformly formed with a plurality of long air outlet holes 3A, and the bottom end of the air return main pipe is fixed with a circular plug with the same diameter. plate 4.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com