Oil storage type motor

A motor housing and oil feeding technology, which is applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of affecting the transmission effect, slowing down the motor shaft speed, and reducing lubricating oil, so as to avoid repeated oil feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

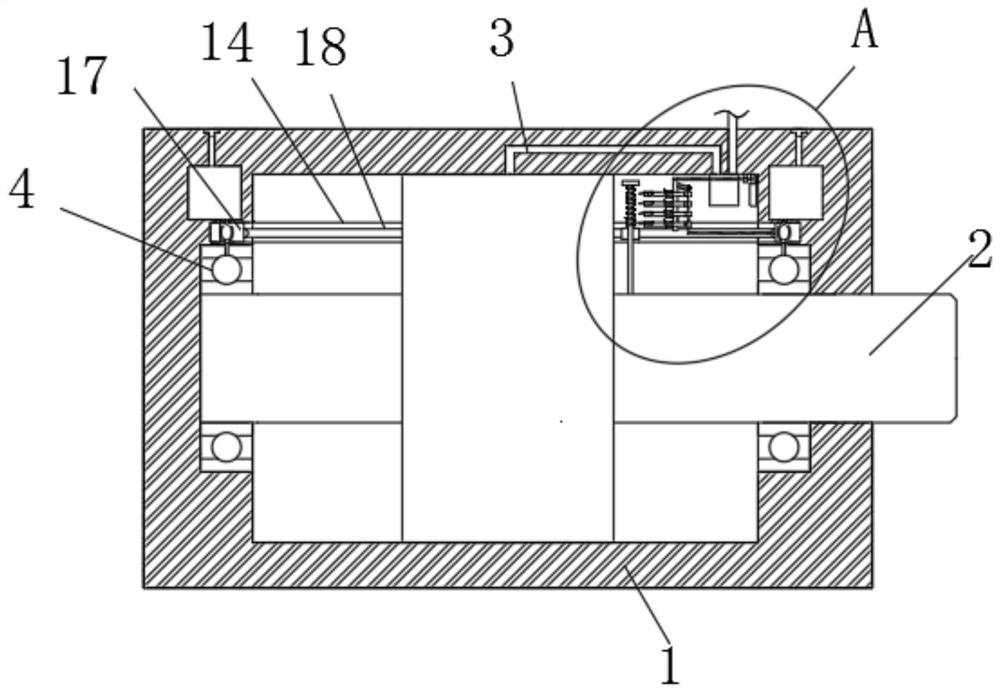

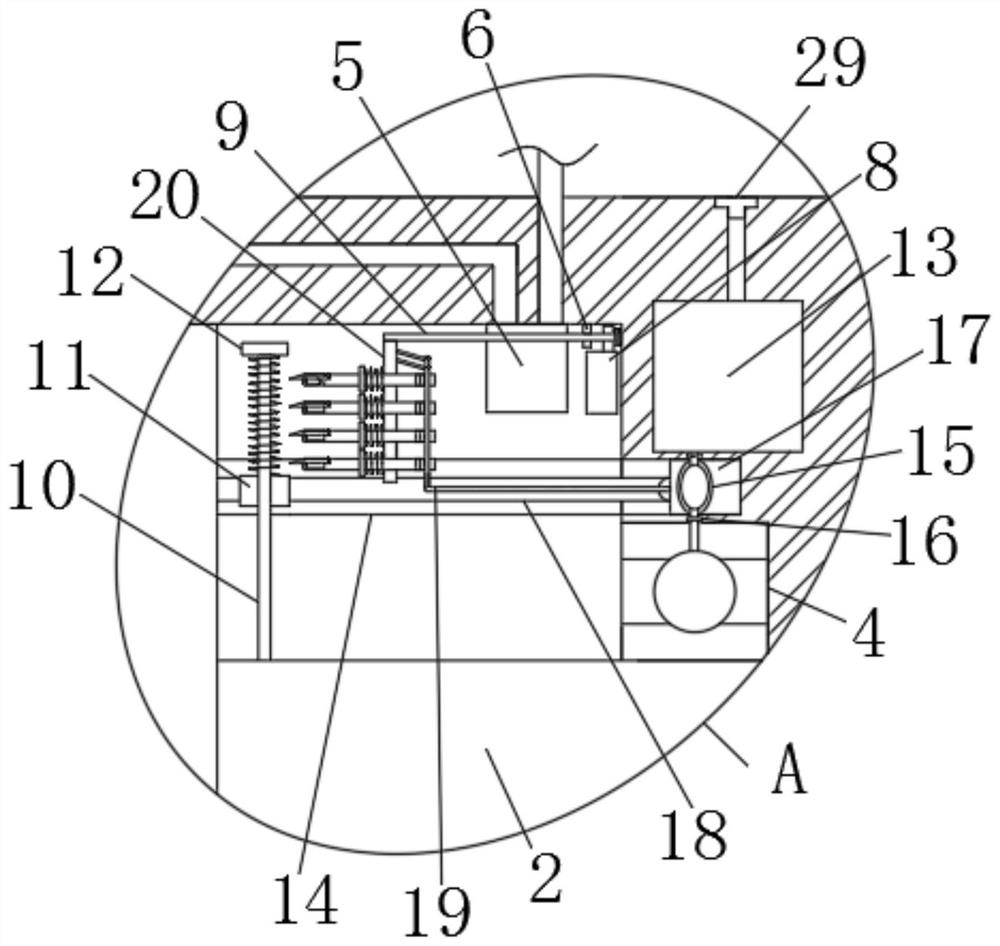

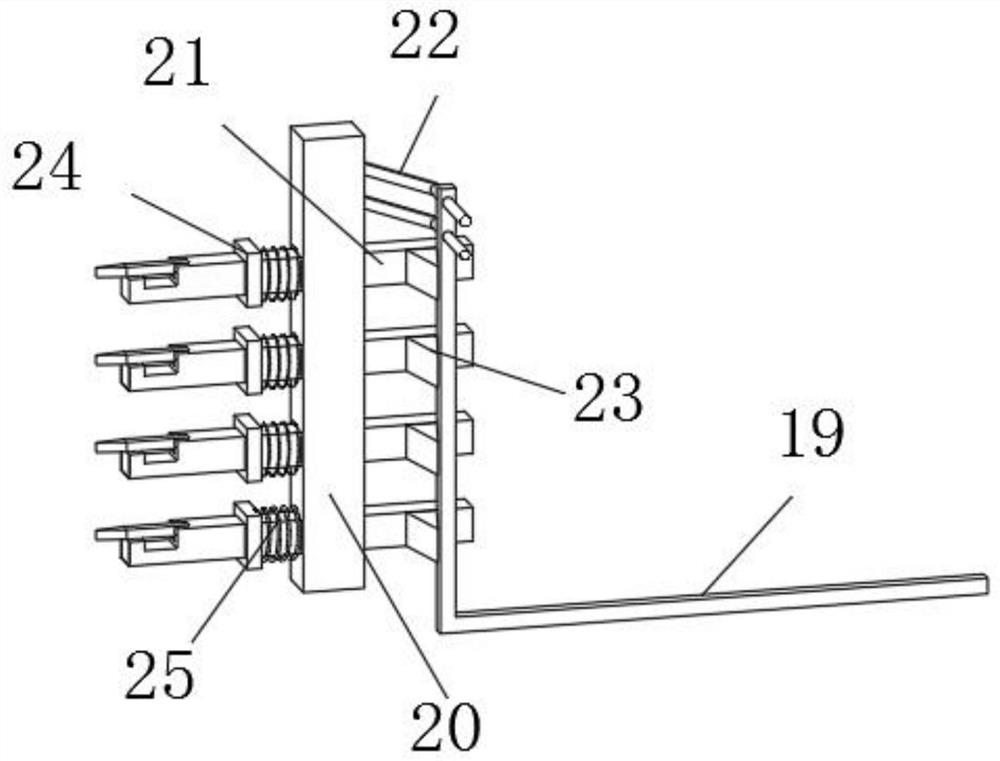

[0040] Example: Reference Figure 1-7 The shown oil storage type motor includes a motor housing 1, a rotating shaft 2 is installed in the motor housing 1 through two bearings 4, a power line 3 is connected to the motor housing 1, and a rotating shaft 2 is mounted on the motor housing 1. Centrifugal moving mechanism is installed, electromagnetic relay 5 in described motor casing 1, and electromagnetic relay 5 is installed on the inner wall of motor casing 1, and the side of electromagnetic relay 5 is provided with suction moving mechanism, and suction moving mechanism is installed with Oil inlet mechanism, an upward avoidance mechanism is installed on the oil inlet mechanism, and the upward avoidance mechanism is compatible with the centrifugal movement mechanism. Two oil storage mechanisms are installed on the motor housing 1, and the two oil storage mechanisms are installed in cooperation with the oil inlet mechanism , the oil storage mechanism communicates with the two beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com