Camellia oil with high content of nutrition ingredients and preparation technology thereof

A technology of nutritional ingredients and camellia oil, applied in the direction of fat oil/fat production, fat generation, fat oil/fat refining, etc., can solve the problems of harmfulness to the human body, achieve good effect, prevent and relieve constipation, and have high sterol content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

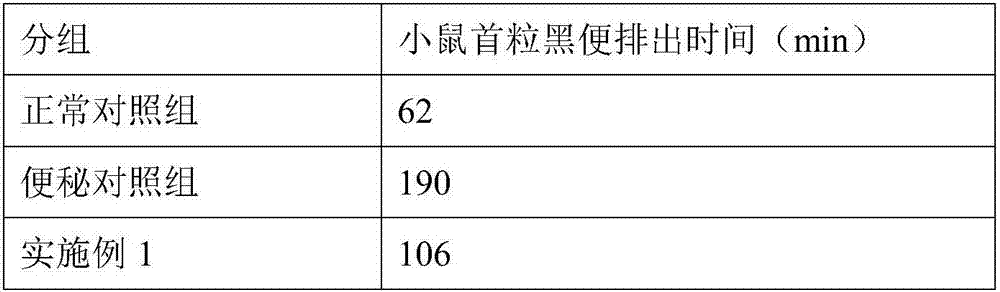

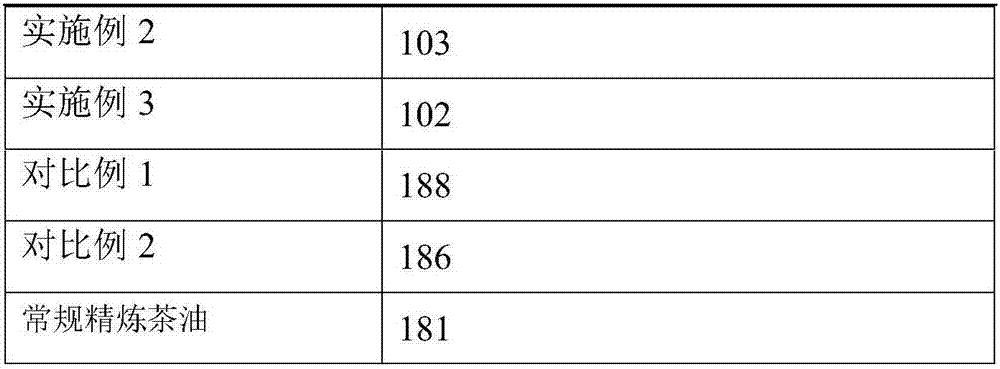

Examples

Embodiment 1

[0025] Embodiment 1: a kind of camellia oil with high nutritional content, its production process is:

[0026] (1) Select the camellia seeds produced in the current year, remove impurities and mildewed camellia seeds, and then dry to a content of 9%. The drying method is sun-dried or hot-air constant-temperature drying, and the temperature of hot-air constant-temperature drying is 60°C;

[0027] (2) After the camellia seeds are crushed, the camellia seed kernels are obtained, and the shell content in the camellia seed kernels is less than 1%, and then the camellia seed kernels are dried at 80°C until the water content is 4%;

[0028] (3) After the camellia seed kernels are cooled to room temperature, they are pressed by a double-screw low-temperature oil press, and the pressed tea oil is removed from solid impurities by a tympanic plate-and-frame filter press;

[0029] (4) Heat the tea oil after impurity removal to 75°C, feed ethylene and carbon dioxide into the tea oil, then ...

Embodiment 2

[0037] Embodiment 2: the difference with embodiment 1 is:

[0038] The flow rate of ethylene in step (4) is 200ml / min, and the flow rate of carbon dioxide is 100ml / min.

[0039] The aqueous solution of the Chinese medicine extract in step (4) is obtained by dissolving 2 parts of the Chinese medicine extract in 100 parts of hot water at 75°C.

[0040] The Chinese medicine extract in the step (4) is obtained by the following method:

[0041] ① Soak 60 parts of goose sausage and 10 parts of bamboo leaf lotus with 200 parts of hydrogen peroxide solution with a mass fraction of 1.5% for 1 day, and rinse the soaked goose intestine and bamboo leaf lotus with water for 2-3 times;

[0042] ②The goose sausage and bamboo leaf lotus treated in step ① were extracted with 800 parts of water at 95°C for 6 hours, then added 40 parts of monk vegetable, continued to extract at 95°C for 2 hours, filtered, and the filtrate was concentrated and dried to obtain a solid powder.

[0043] All the ot...

Embodiment 3

[0044] Embodiment 3: the difference with embodiment 1 is:

[0045] The flow rate of ethylene in step (4) is 300ml / min, and the flow rate of carbon dioxide is 50ml / min.

[0046] The aqueous solution of the Chinese medicine extract in step (4) is obtained by dissolving 5 parts of the Chinese medicine extract in 100 parts of hot water at 75°C.

[0047] The Chinese medicine extract in the step (4) is obtained by the following method:

[0048] ① soak 90 parts of goose sausage and 20 parts of bamboo leaf lotus with 200 parts of hydrogen peroxide solution with a mass fraction of 0.5% for 1 day, and rinse the soaked goose intestine and bamboo leaf lotus with water for 2-3 times;

[0049] ②The goose sausage and bamboo leaf lotus treated in step ① were extracted with 600 parts of water at 90°C for 5 hours, then added 50 parts of monk vegetable, continued to extract at 90°C for 1 hour, filtered, and the filtrate was concentrated and dried to obtain a solid powder.

[0050] All the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com