Luminescent ceramic, LED packaging structure and preparation method of luminescent ceramic

A technology of luminescent ceramics and lasers, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of white LED color ring and affect the color uniformity of the light angle, and achieve the effect of uniform color and good luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

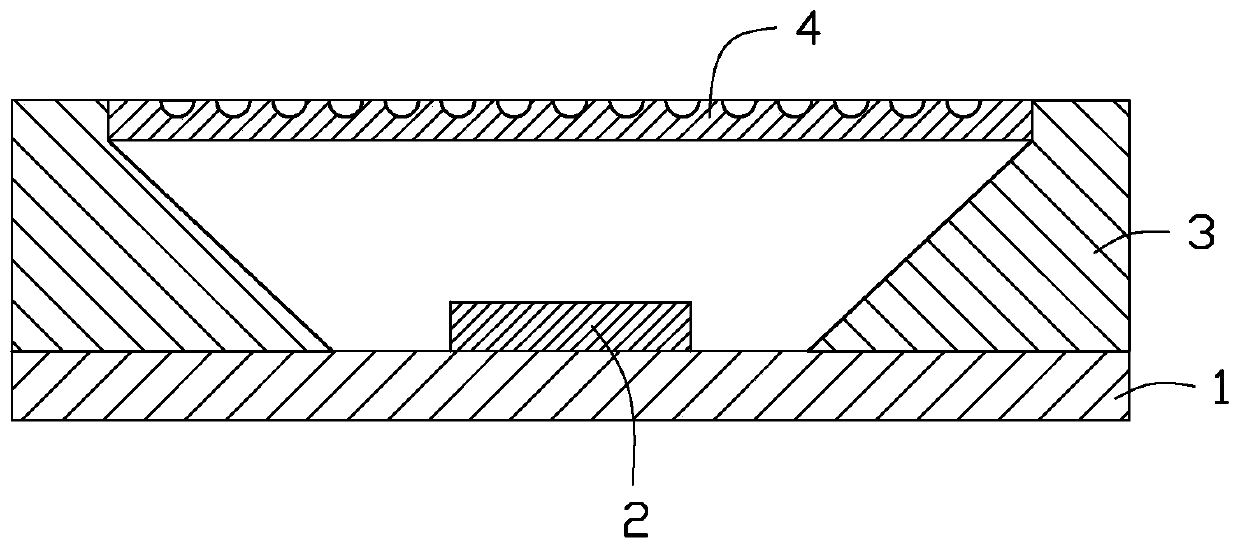

[0035] The present invention also provides a preparation method of luminescent ceramics, comprising:

[0036] Prepare luminescent ceramic raw materials;

[0037] The luminescent ceramic raw material is irradiated with a predetermined specification laser, and a depression is processed on the surface of the luminescent ceramic raw material;

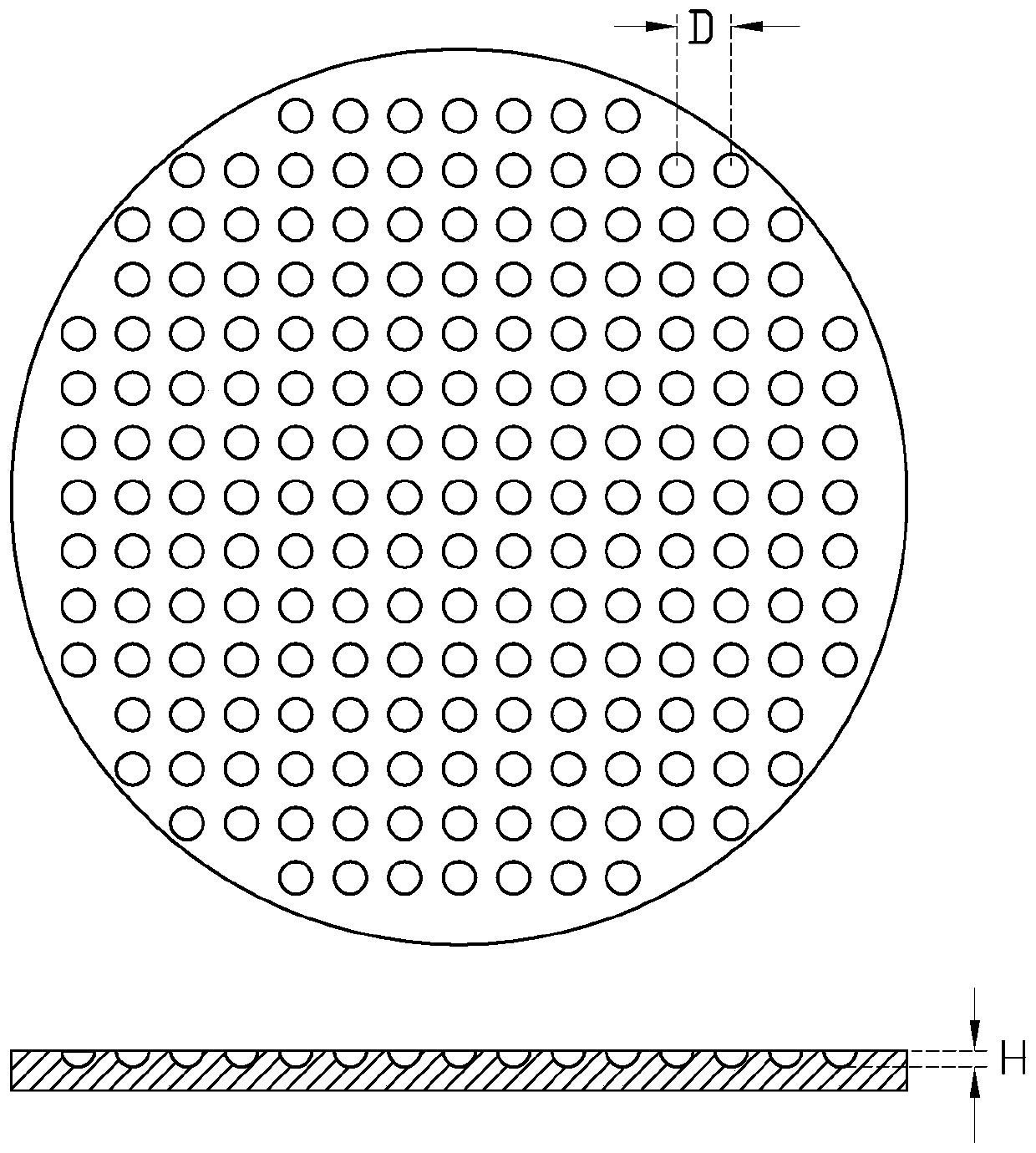

[0038] The surface of the luminescent ceramic raw material is scanned and irradiated with the predetermined specification laser in a fast scanning mode, and a plurality of the depressions are processed on the surface of the luminescent ceramic raw material, and the depressions are arranged in an orderly manner on the surface of the luminescent ceramic raw material. The ratio of the diameter to the depth of each depression is between 2:1 and 3:1 to prepare the luminescent ceramic;

[0039] The parameters of the laser of the predetermined specification include: the laser pulse duration is 20-100 ns, the pulse repetition rate is 1 kHz, the po...

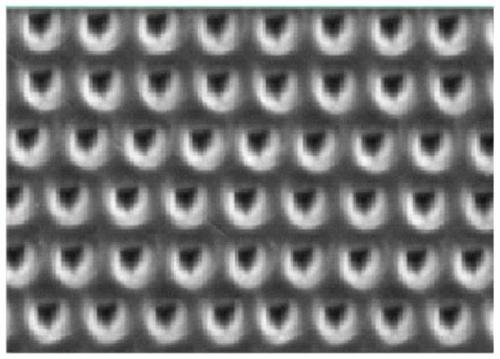

Embodiment 1

[0048] Ce is obtained by vacuum heat treatment 3+ The Φ15mm transparent YAG ceramic with a molar concentration of 0.3% was ground and polished to obtain a ceramic sheet with a thickness of 0.3mm. The polished transparent ceramic surface was irradiated with a 355nm laser pulse. The laser pulse duration was 40ns, the pulse repetition rate was 1kHz, the power was 0.2W, and the diameter of the laser spot was 10μm. The obtained hemispherical concave diameter D was about 15 μm, the depth H is approximately equal to 5 μm. Control the spacing distance between each depression a=b=20μm, obtain the sequence distribution of depressions by fast scanning mode, and then soak and wash in 98wt% concentrated sulfuric acid solution at 70°C for 1min, and finally obtain as follows: Figure 3a and Figure 3b The surface topography of the luminescent ceramic after treatment is shown.

[0049] The luminescent ceramic prepared in Example 1 was packaged into an LED light source for testing. The wave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com