Oily sewage separator

A separator, oily sewage technology, applied in liquid separation, separation methods, mining wastewater treatment and other directions, can solve the problems of substandard sewage, low separation efficiency, inability to separate oil droplets, etc., to achieve separation effect and efficiency improvement, separation effect Good, processing cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

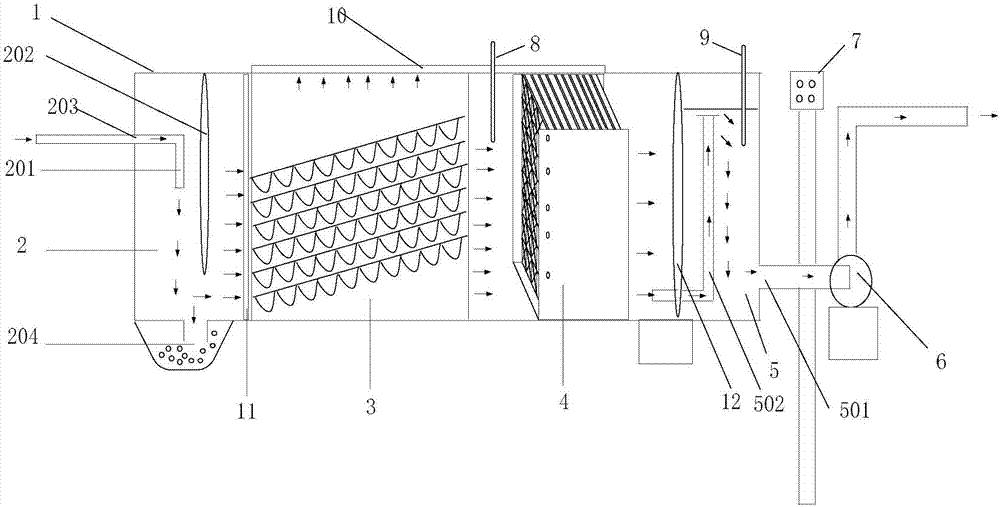

[0053] Such as Figure 1-Figure 13 Shown is an oily sewage separator 1, one end of the above separator is at least provided with an oily sewage inlet 201, and the other end is at least provided with a sewage discharge outlet 501; from the above inlet 201 to the above outlet 501, the above separator sequentially includes: Treatment device 2, used for separating the sludge in the above-mentioned oily sewage;

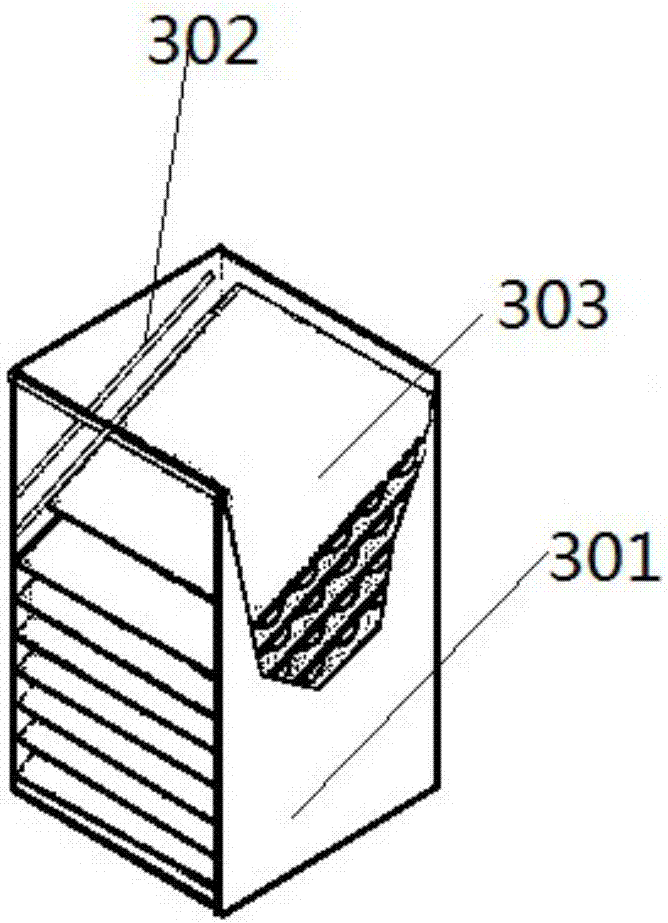

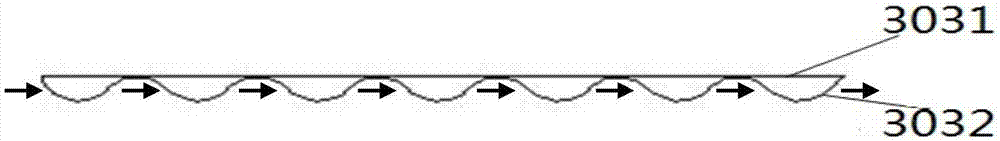

[0054] The inclined plate separation device 3, whose top and bottom ends are closely connected with the top and bottom ends of the above-mentioned separator respectively, and the above-mentioned inclined plate separation device is used for primary oil-water separation;

[0055] Coagulation and separation device 4, the top and bottom of which are closely connected with the top and bottom of the above-mentioned separator respectively, and the above-mentioned coagulation and separation device is used for secondary oil-water separation;

[0056] The top of the separator is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com