Electrically operated tricycle

A technology for electric tricycles and front wheels, which is used in motor vehicles, bicycles, tire measurement, etc., can solve the problems of easily damaged tire service life, severe tire wear, etc., and achieve the effect of convenient and long-term use, long service life and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

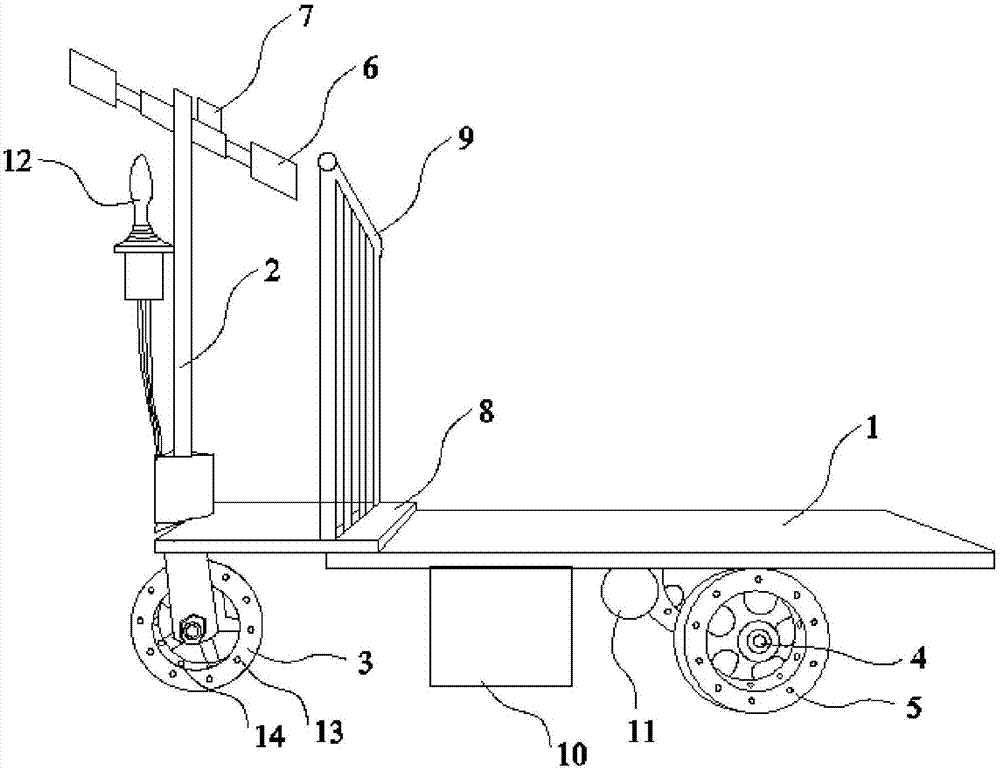

[0026] See figure 1 , The embodiment of the present invention provides an electric tricycle, including a base plate 1 , a faucet 2 , a front wheel 3 , a rotating shaft 4 and two rear wheels 5 . The faucet 2 is installed on one end of the base plate 1, and the front wheel 3 is installed below the faucet 2 and connected to the faucet 2. Two handlebars 6 are installed on the end of the faucet 2 away from the front wheel 3, and the two handlebars 6 are respectively located on both sides of the faucet 2, which are used to facilitate the staff to operate the electric tricycle and control the driving direction of the electric tricycle. The rotating shaft 4 is installed below the base plate 1, and the two rear wheels 5 are installed at the two ends of the rotating shaft 4 respectively. In this embodiment, two ends of the rotating shaft 4 are covered with a sleeve (not shown) adapted to the rotating shaft 4, and the sleeve is connected to the bottom of the bottom plate 1 by welding. ...

Embodiment 2

[0031] In this embodiment, except that the components by weight of the millable polyurethane are different, the others are the same as in Embodiment 1.

[0032]In this embodiment, the mixing type polyurethane includes the following components by weight: 90 parts of unsaturated polyurethane raw rubber, 1.2 parts of stearic acid, 3 parts of zinc stearate, 30 parts of carbon black, precipitate 28 parts of white carbon black, 1.3 parts of silane coupling agent, 7 parts of coumarone resin, 6 parts of plasticizer, 1.5 parts of active agent, 2.5 parts of accelerator MBT, 2.5 parts of accelerator MBTS, 2 parts of accelerator CZ, 2 parts of sulfur, 1.5 parts of microcrystalline wax, 1.5 parts of phenolic antioxidant and 8 parts of antistatic agent.

Embodiment 3

[0034] In this embodiment, except that the components by weight of the millable polyurethane are different, the others are the same as in Embodiment 1.

[0035] In this embodiment, the mixing type polyurethane includes the following components by weight: 110 parts of unsaturated polyurethane raw rubber, 2.1 parts of stearic acid, 5 parts of zinc stearate, 50 parts of carbon black, precipitate 48 parts of white carbon black, 2.3 parts of silane coupling agent, 12 parts of coumarone resin, 10 parts of plasticizer, 2.5 parts of active agent, 4.5 parts of accelerator MBT, 4.5 parts of accelerator MBTS, 3 parts of accelerator CZ, 3 parts of sulfur, 2 parts of microcrystalline wax, 3 parts of phenolic antioxidant and 10 parts of antistatic agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com