A metal tabular body and columnar body riveting assembling product and a method and a device for manufacturing the same

A manufacturing method and metal technology, applied in the direction of electromechanical devices, manufacturing motor generators, and motor components, etc., can solve the problems of increased cost, expensive equipment, increased manufacturing cost, etc., and achieve a wide range of function selection and material selection range. Wide, firm joint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

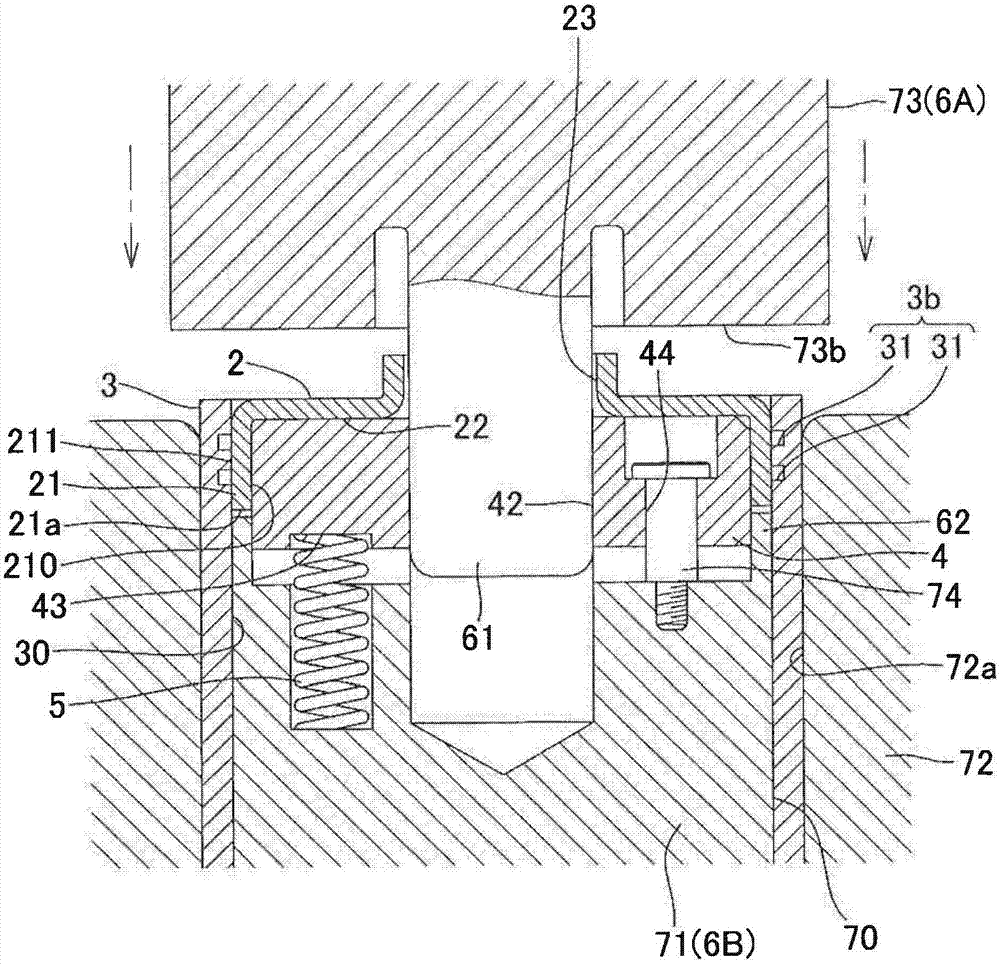

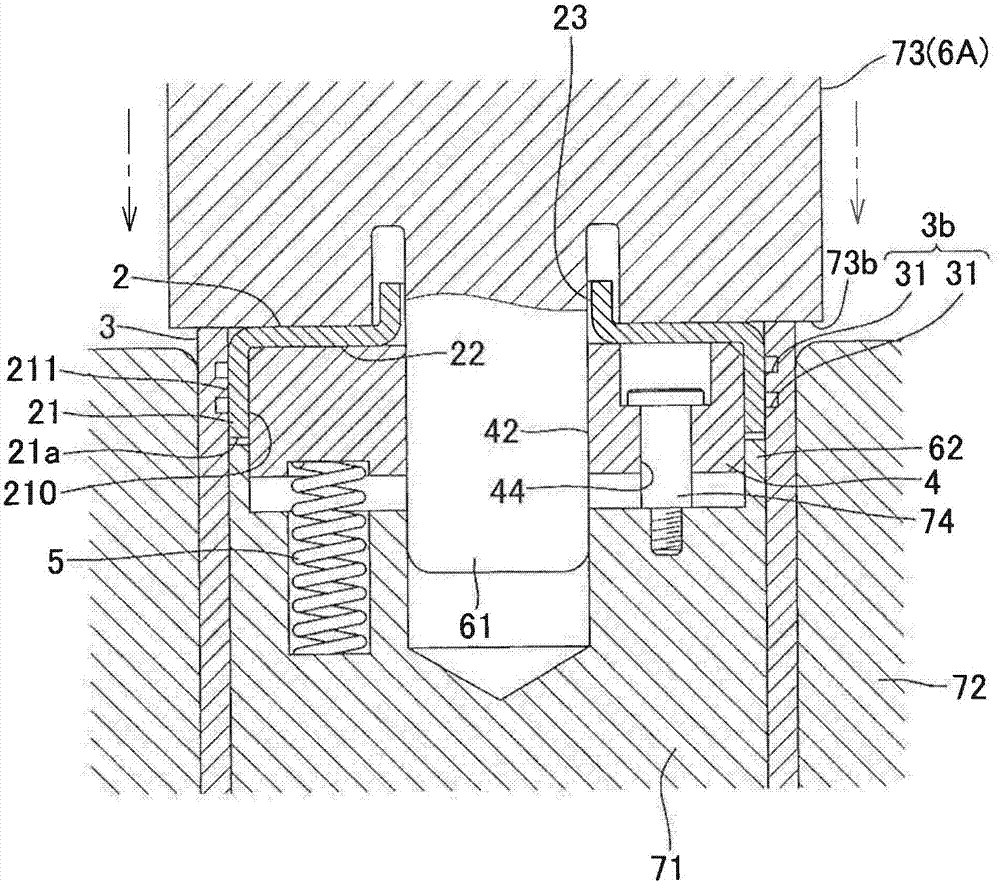

[0079] Next, embodiments of the present invention will be described in detail based on the drawings.

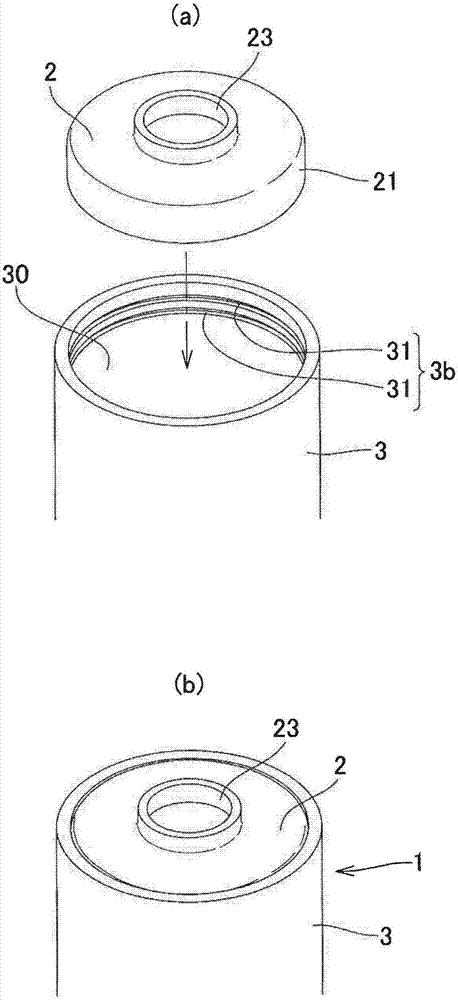

[0080] figure 1 (a) represents the metal plate-shaped body 2 and the pipe body 3 used in the riveted assembly of the present invention, figure 1 (b) shows the caulked assembly 1 obtained by assembling the metal plate-shaped body 2 and the pipe body 3 by caulking. The riveted assembly 1 of the present invention is suitably used as a cylindrical casing of a motor, a cylindrical frame of a rotor, or other bearing bodies for attaching a bearing member supporting a rotating shaft to the center of a metal plate-shaped body 2 or fixing the rotating shaft. Or a cylindrical frame of a rotating body, but it is not limited to the use of providing such a shaft portion, and can be applied to other various parts and products.

[0081] A curved piece 21 along the inner peripheral surface 30 of the tubular body 3 is formed on the outer peripheral portion of the metal plate-shaped body 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com