Grain cooling and storage box

A storage and grain technology, applied in application, grain processing, grain milling, etc., can solve the problems of difficulty in reducing the temperature of rice, the rice cannot be completely cooled, and the contact time is short. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

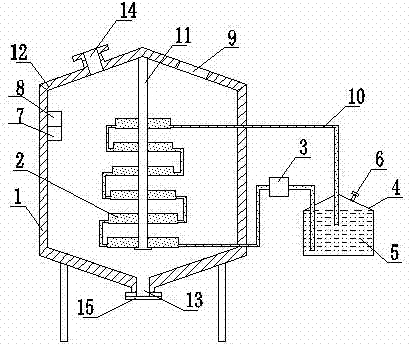

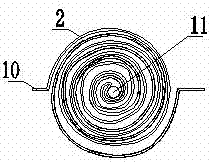

[0025] Such as Figure 1 to Figure 2 As described above, a grain cooling storage box includes a box body 1, a heat absorbing plate 2, a water pump 3, a hose 10, a boom 11 and a box cover 12, and the box cover 12 is closed at the top opening of the box body 1, The upper end of the suspender 11 is connected to the case cover 12, the lower end of the suspender 11 is close to the bottom of the box 1, the suspender 11 and the heat absorbing plate 2 are assembled in the box 1, and the heat absorbing plate 2. It is arranged in multiple layers from the lower end of the suspender 11. A water storage tank 4 is arranged outside the box body 1. The water storage tank 4 contains cooling water 5. The temperature-absorbing plate 2, the water pump 3 and the water storage tank 4 is connected through the hose 10 to realize the circulation of the cooling water 5 .

[0026] The heat-absorbing plate 2 is assembled on the suspender 11 and arranged in multiple layers, and the heat-absorbing plate 2...

Embodiment 2

[0028] Such as Figure 1 to Figure 2 As described above, a grain cooling storage box includes a box body 1, a heat absorbing plate 2, a water pump 3, a hose 10, a boom 11 and a box cover 12, and the box cover 12 is closed at the top opening of the box body 1, The upper end of the suspender 11 is connected to the case cover 12, the lower end of the suspender 11 is close to the bottom of the box 1, the suspender 11 and the heat absorbing plate 2 are assembled in the box 1, and the heat absorbing plate 2. It is arranged in multiple layers from the lower end of the suspender 11. A water storage tank 4 is arranged outside the box body 1. The water storage tank 4 contains cooling water 5. The temperature-absorbing plate 2, the water pump 3 and the water storage tank 4 is connected through the hose 10 to realize the circulation of the cooling water 5 .

[0029] The upper case cover 12 is provided with a grain inlet 14 and a vent 9, and an exhaust fan is installed on the vent 9.

[...

Embodiment 3

[0033] Such as Figure 1 to Figure 2 As described above, a grain cooling storage box includes a box body 1, a heat absorbing plate 2, a water pump 3, a hose 10, a boom 11 and a box cover 12, and the box cover 12 is closed at the top opening of the box body 1, The upper end of the suspender 11 is connected to the case cover 12, the lower end of the suspender 11 is close to the bottom of the box 1, the suspender 11 and the heat absorbing plate 2 are assembled in the box 1, and the heat absorbing plate 2. It is arranged in multiple layers from the lower end of the suspender 11. A water storage tank 4 is arranged outside the box body 1. The water storage tank 4 contains cooling water 5. The temperature-absorbing plate 2, the water pump 3 and the water storage tank 4 is connected through the hose 10 to realize the circulation of the cooling water 5 .

[0034] The upper case cover 12 is provided with a grain inlet 14 and a vent 9, and an exhaust fan is installed on the vent 9.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com