Catalyst used for preparing low-carbon alkene by dehydrogenation of low-carbon alkane and process method of catalyst

A technology of low-carbon alkanes and low-carbon olefins, applied in the field of catalysts, can solve the problems of serious carbon deposition, poor single-pass stability, and low olefin selectivity, and achieve the effects of reducing carbon deposition, improving catalyst performance, and high olefin selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

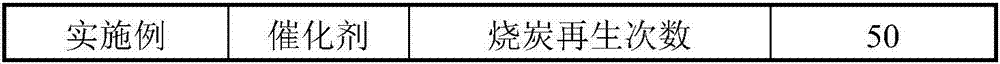

Examples

Embodiment 1

[0026] Weigh an appropriate amount of MgAl 2 o 4 Carrier, added to containing appropriate amount of chloroplatinic acid (H 2 PtCl 6 .6H 2 O), anhydrous tin tetrachloride (SnCl 4 ) in a mixed aqueous solution at 60°C for 2 hours, and then dry the soaked sample in an oven at 110°C for 4 hours. The raw materials used are of high purity. The dried samples were calcined at 600°C for 4 hours in a muffle furnace, and then reduced by hydrogen at 500°C for 2 hours. Before the prepared sample was used in the catalytic dehydrogenation reaction, it was treated with water vapor at 500° C. for 2 hours to obtain catalyst A, which was ground into 40-60 mesh particles for catalyst evaluation. The loading of Pt in the catalyst A is 0.3% of the catalyst weight, the loading of Sn is 0.4% of the catalyst weight, and the catalyst also contains Hg 180ppm, Pb 160ppm, and Ti 100ppm in mass fraction.

Embodiment 2

[0028]Weigh an appropriate amount of MgAl 2 o 4 Carrier, added to containing appropriate amount of chloroplatinic acid (H 2 PtCl 6 .6H 2 O), anhydrous tin tetrachloride (SnCl 4 ) in an ethanol solution at 60°C for 2 hours, and then dry the soaked sample in an oven at 110°C for 4 hours. The raw materials used are of high purity. The dried samples were calcined at 600°C for 4 hours in a muffle furnace, and then reduced by hydrogen at 500°C for 2 hours. Before the prepared sample was used in the catalytic dehydrogenation reaction, it was treated with water vapor at 500°C for 2 hours to obtain catalyst B, which was ground into 40-60 mesh particles for catalyst evaluation. The loading of Pt in the catalyst B is 0.1% of the catalyst weight, the loading of Sn is 0.2% of the catalyst weight, and the catalyst also contains 80ppm of Hg, 60ppm of Pb and 50ppm of Ti in terms of mass fraction.

Embodiment 3

[0030] Weigh an appropriate amount of MgAl 2 o 4 Carrier, added to containing appropriate amount of chloroplatinic acid (H 2 PtCl 6 .6H 2 O), anhydrous tin tetrachloride (SnCl 4 ) in a mixed aqueous solution at 10°C for 24 hours, and then the soaked sample was dried in an oven at 90°C for 24 hours. The raw materials used are of high purity. The dried samples were calcined at 400°C for 24 hours in a muffle furnace, and then reduced by hydrogen at 400°C for 10 hours. Before the prepared sample was used in the catalytic dehydrogenation reaction, it was treated with water vapor at 500°C for 2 hours to obtain catalyst C, which was ground into 40-60 mesh particles for catalyst evaluation. The loading amount of Pt in the catalyst C is 0.8% of the catalyst weight, the loading amount of Sn is 1.0% of the catalyst weight, and the catalyst also contains Hg240ppm, Pb200ppm and Ti150ppm in mass fraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com