Internal combustion engine and method for detecting leak from crankcase and/or tank ventilation system

A crankcase ventilation, internal combustion engine technology, applied in crankcase ventilation, combustion air/combustion-air treatment, charging system, etc., can solve difficult monitoring, monitoring does not cause any problems, etc., to achieve simple cost, accurate detection of leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

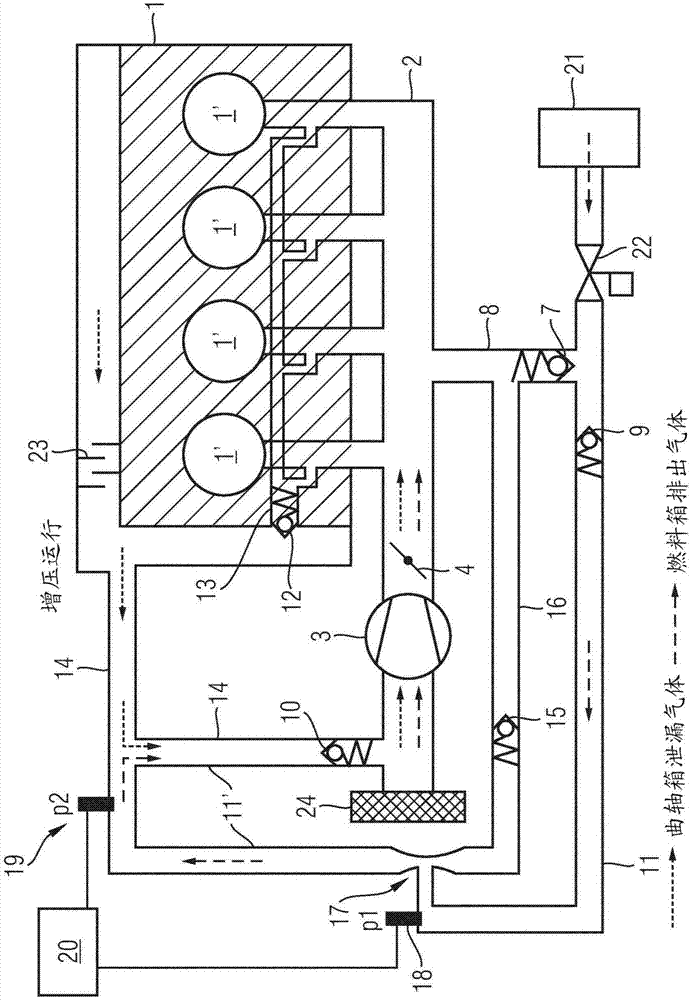

[0020] the following in Figures 1 to 3 In , the same reference numerals are applied to the same components.

[0021] figure 1 Shown is a schematic diagram of an internal combustion engine 1 according to the invention, which has, for example, four drawn cylinder blocks 1' denoted by circles and has a combustion air intake system 2 in which a combustion air intake system is arranged A compressor 3 (for example of an exhaust gas turbocharger) or a mechanical compressor, downstream of which a throttle (for example of a throttle valve) is arranged in the flow direction of the combustion air (indicated by the arrow in the compressor) Flow element 4. Furthermore, internal combustion engine 1 has a fuel tank ventilation system 5 for a fuel tank 21 and has a crankcase ventilation system 6 . The spatial separation of fuel tank ventilation system 5 and crankcase ventilation system 6 is indicated schematically by arrows.

[0022] The fuel tank ventilation system 5 can be connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com