Raw material pitch for carbon fiber manufacturing

A technology of carbon fiber manufacturing and carbon fiber, which is applied in the field of pitch as a raw material for carbon fiber manufacturing, can solve problems such as raising the cost of carbon fiber manufacturing, and achieve the effect of cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

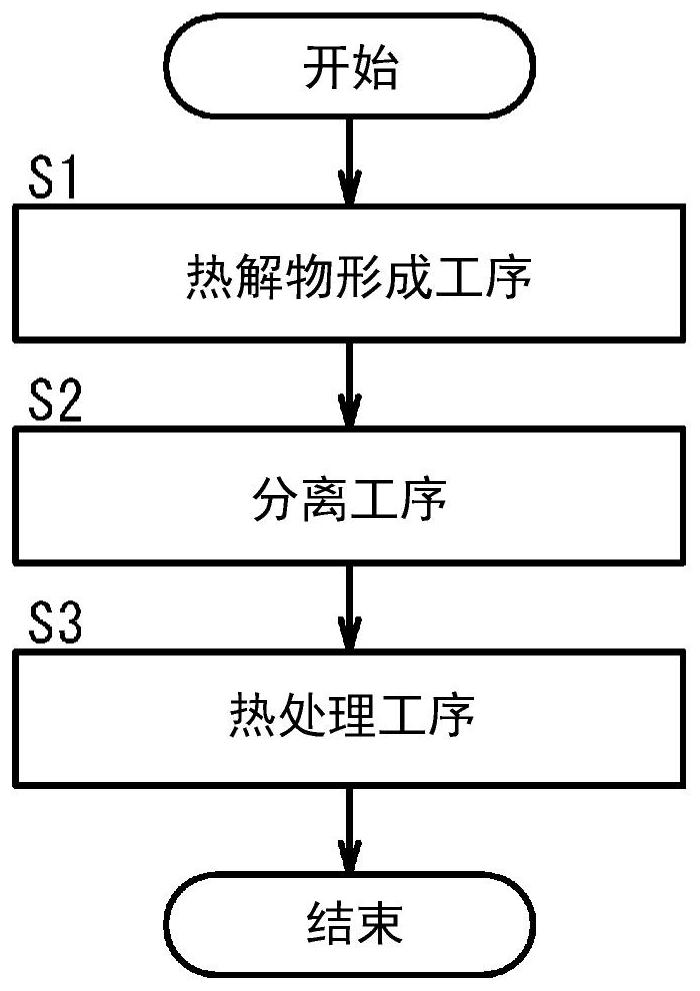

Method used

Image

Examples

Embodiment approach

[0077] The above-mentioned embodiments do not limit the configuration of the present invention. Therefore, in the above-mentioned embodiment, omission, replacement or addition of constituent elements of each part of the above-mentioned embodiment may be made based on the description of this specification and technical common sense, and it should be construed that all of these belong to the scope of the present invention.

[0078] As an example, in this method of producing raw material pitch for carbon fiber production, the ash and the like in the slurry may not be separated from the ash-free coal in the pyrolyzed product forming process, but the ash and the like may be separated from the ash and the like in the next separation process. The insoluble components in the ashless coal are separated together.

[0079] In addition, in the production method of the raw material pitch for carbon fiber production, the heat treatment step may be omitted.

[0080] 【Example】

[0081] Here...

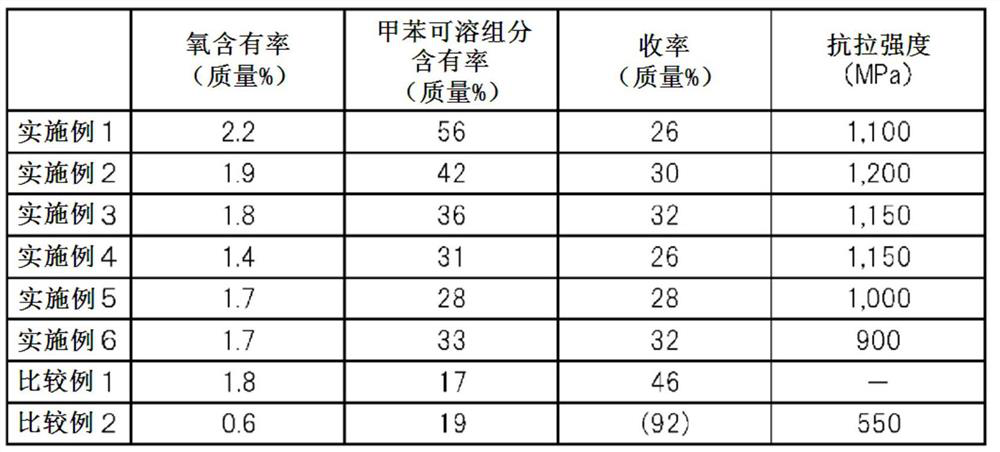

Embodiment 1

[0085] As the raw coal, bituminous coal produced in Australia with an oxygen content of 6.5% by mass on an anhydrous and ash-free basis was used. First, 1 kg of the above-mentioned bituminous coal pulverized to 1 mm or less was mixed with 5 kg of methylnaphthalene, charged into an autoclave, kept at 400° C. for 1 hour in a nitrogen atmosphere, and then cooled to obtain a pyrolyzed product. Next, 5 kg of methylnaphthalene was further added to the pyrolyzed product, stirred at an extraction temperature of 60° C. for 1 hour, the soluble components were extracted, filtered, and the obtained filtrate was distilled under reduced pressure to separate the soluble components. This soluble component was heat-treated for 1 hour in a nitrogen atmosphere at a heat treatment temperature of 230° C., whereby the raw material pitch for carbon fiber production of Example 1 was obtained.

Embodiment 2

[0087] In Example 2, trial production was carried out under the same conditions as in Example 1 above, except that the extraction temperature was 80°C. In Example 3, trial production was carried out under the same conditions as in Example 1 above, except that the extraction temperature was 100°C. In Example 4, a trial production was carried out under the same conditions as in Example 1 above except that the heat treatment temperature was set to 250°C. In Example 5, trial production was carried out under the same conditions as in Example 1 above, except that the extraction temperature was 80°C and the heat treatment temperature was 250°C. In Example 6, trial production was carried out under the same conditions as in Example 1 above, except that the extraction temperature was 100°C and the heat treatment temperature was 250°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com