Stepping type heating furnace vaporization cooling device capable of generating superheated steam

A technology of walking heating furnace and superheated steam, which is applied to the steam generation method using heat carrier, lighting and heating equipment, furnace, etc., which can solve the problems of poor steam quality, achieve less fuel consumption, improve energy quality, The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

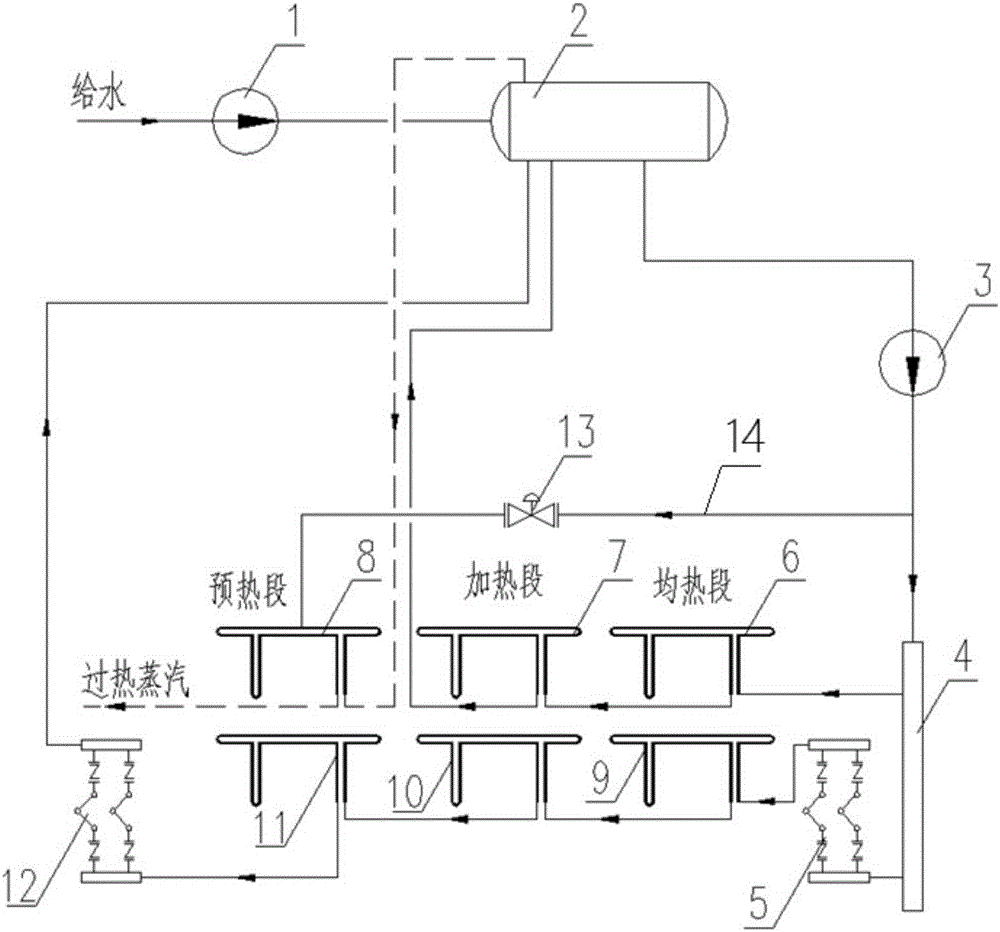

[0027] Such as figure 1 As shown, the waste heat recovered in this embodiment is the waste heat in the fixed beams and movable beams supporting the billet movement in the furnace of the heating furnace. The vaporization cooling device includes a water feed pump 1, a steam drum 2, a hot water circulation pump 3, a distribution header 4, a water beam for generating superheated steam, and a water beam for generating steam-water mixture. The feed water pump 1 and the steam drum 2 are arranged outside the furnace of the heating furnace, the water inlet of the feed water pump 1 communicates with the external water supply, and the water outlet of the feed water pump 1 communicates with the water inlet of the steam drum 2 . The water outlet of the steam drum 2 is connected to the water inlet of the hot water circulation pump 3, the water outlet of the hot water circulation pump 3 is connected to the distribution header 4, and the water from the steam drum 2 is pumped into the distribu...

Embodiment 2

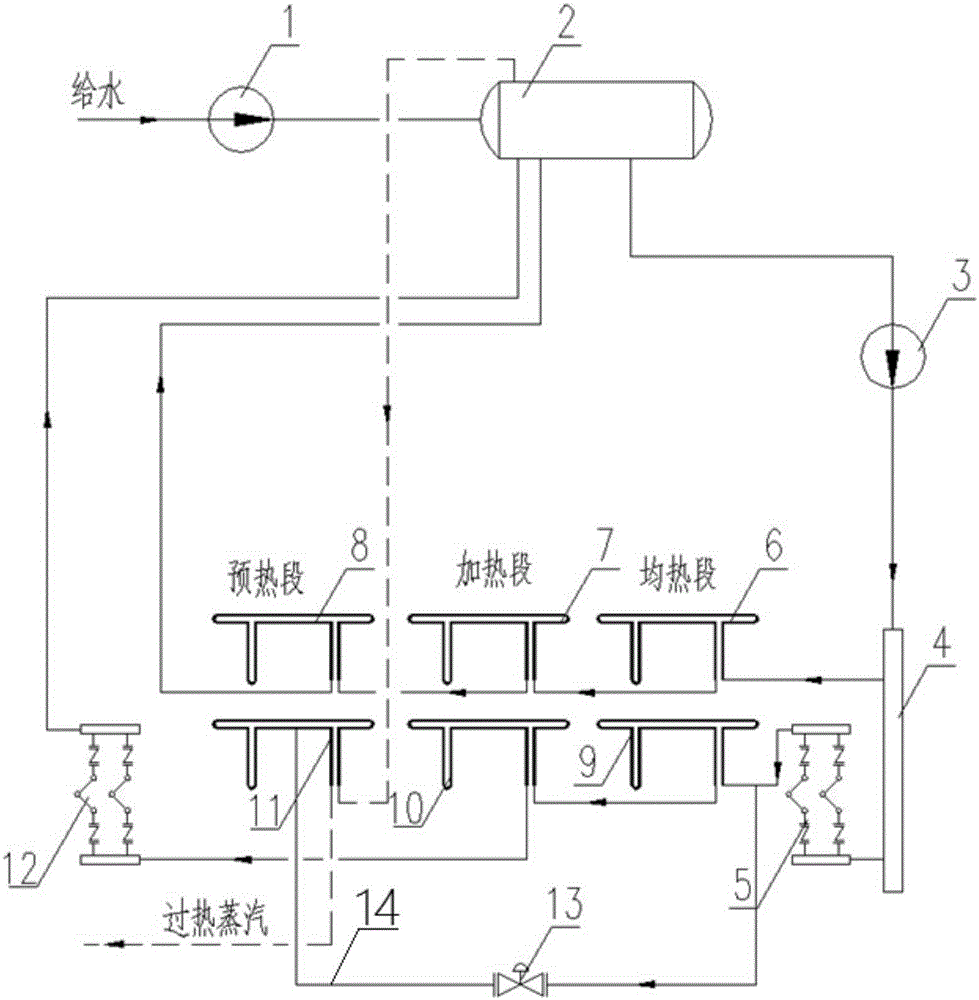

[0033] Such as figure 2 As shown, the difference from Example 1 is that the superheated steam generating water beam is the preheating section movable water beam 11 arranged on the preheating section movable beam, and the steam-water mixture generating water beam includes the preheating section fixed beam. Fixed water beam 8 in the preheating section, fixed water beam in the heating section of the fixed beam in the heating section 7, fixed water beam in the soaking section set on the fixed beam in the soaking section 6, movable water beam in the heating section set on the movable beam in the heating section 10 and the soaking section movable water beam 9 arranged on the soaking section movable beam. Two circulating water outlets on the distribution header, one of which is connected in series with the fixed water beam 6 in the soaking section, the fixed water beam 7 in the heating section and the fixed water beam 8 in the preheating section in sequence, that is, the fixed water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com