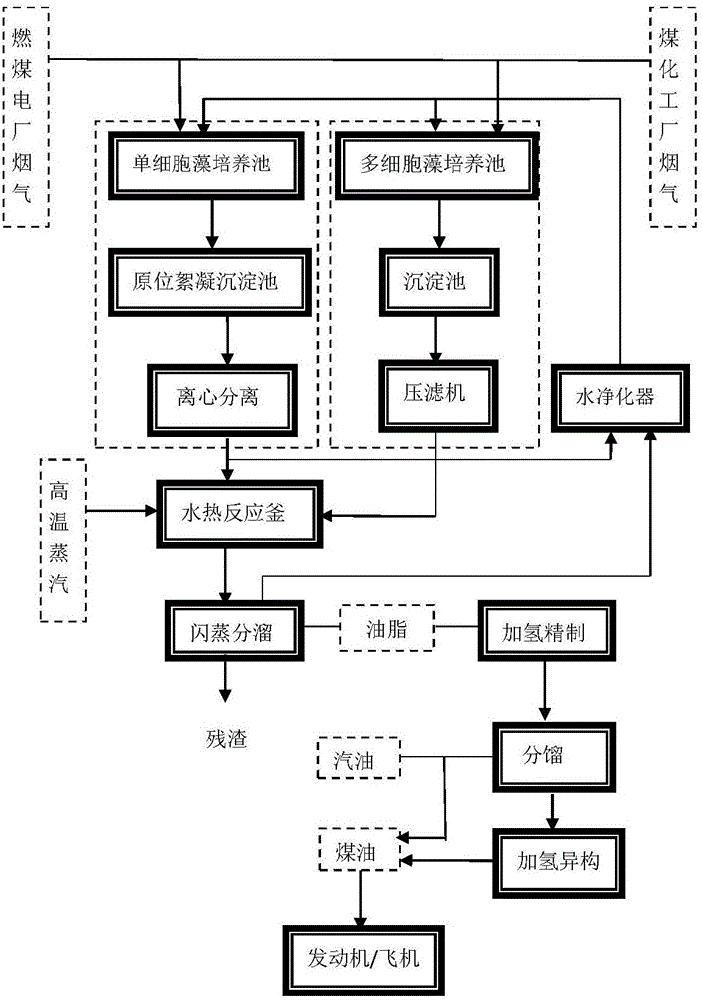

Preparation method and system of low-carbon biological aviation fuel based on full life cycle

A full-life cycle, aviation fuel technology, applied in biochemical equipment and methods, biofuels, bio-raw materials, etc., to achieve the effects of avoiding fertilizers, less energy consumption, and high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] (1) Screening of microalgae: the selected oil content is 20-44%, and the growth rate is 20-30g / m 2 d, Nannochloropsis with carbon spectrum C14, C16, C18;

[0111] (2) Coal-fired power plant CO 2 Purify or pass directly into the microalgae culture pool, adjust CO by controlling pH 2 Influx, the pH is controlled between 5.5-7.8; Nannochloropsis achieves in-situ harvesting by controlling the pH value, and the pH value of in-situ harvesting is between 4.0-4.8 under acidic conditions, and the pH value of in-situ harvesting is also Under the alkaline condition of 9.5-10.5, the in-situ harvesting concentration can reach 20-30g / L, and the concentration after centrifugal dehydration is 150-250g / L. The water recovered by the harvesting and dehydration process is returned to the cultivation pool after filtration and disinfection;

[0112] (3) The microalgae slurry is sent into the hydrothermal reaction kettle heated to the set temperature through a high-pressure pump. The temper...

Embodiment 2

[0117] (1) Screening of microalgae: the selected oil content is 30-65%, and the growth rate is 20-30g / m 2 d, carbon spectrum C14, C16, C18 multicellular yellow hair algae;

[0118] (2) Coal chemical plant CO 2 After purification, it is directly passed into the culture pool of the yellow hair algae, and the CO is adjusted by controlling the pH. 2 Influx, pH is controlled between 5.5-7.8; multicellular Xanthophyllum can be harvested directly without dehydration process due to its large size. Use nylon sieves with specifications of 200-400 mesh for rapid filtration, squeeze and dehydrate The concentration is 350g / L, and the water recovered by the harvesting and dehydration process is returned to the cultivation pool after filtration and disinfection;

[0119] (3) The microalgae slurry is sent into the hydrothermal reaction kettle heated to the set temperature through a high-pressure pump. The temperature of the reaction kettle is controlled at 270-300°C, and nitrogen is regular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Total acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com