Process control method for glass plate tempering process

A technology of process and control method, which is applied in glass tempering, glass manufacturing equipment, temperature control by electric means, etc., can solve problems such as heating furnace temperature error, and achieve easy monitoring, which is beneficial to production process and product quality, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

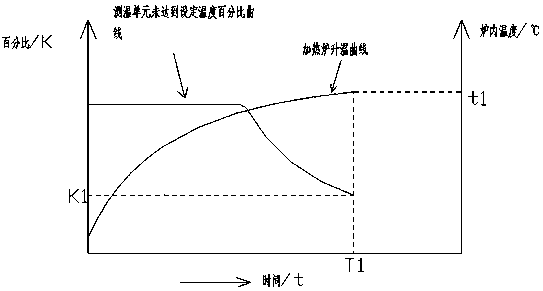

[0030] Such as figure 1 As shown, the executive mechanism is a driving mechanism for controlling the movement of the glass plate into the furnace, and the control process of the heating control method of the present invention is as follows:

[0031] First determine the heating furnace to be used, adjust the working temperature of the heating furnace according to the type of glass plate to be heated (such as low-emissivity coated glass, clear glass) and thickness information, and run the heating furnace at room temperature without load to reach the working temperature. Monitor the percentage of the number of temperature measuring units that have not reached the set temperature of the heating element in this state to the total number of temperature measurement units, and measure the percentage of the number of temperature measurement units that have not reached the set temperature at five different times The percentage of the number of units, average the five values, and the ave...

Embodiment 2

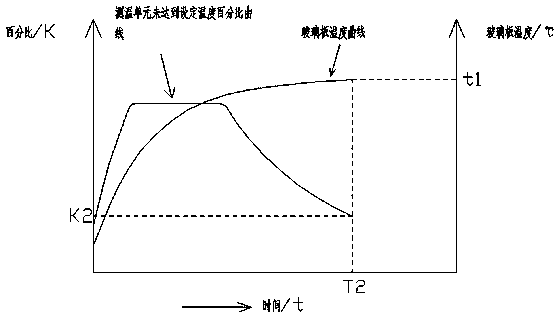

[0034] Such as figure 2 As shown, the executive mechanism is a driving mechanism for controlling the movement of the glass plate out of the furnace. The control process of the heating control method of the present invention is as follows:

[0035] First determine the heating furnace to be used, adjust the working temperature of the heating furnace according to the type of glass plate to be heated (such as low-emissivity coated glass, clear glass) and thickness information, and run the heating furnace at room temperature without load to reach the working temperature. Monitor the percentage of the number of temperature measuring units that have not reached the set temperature of the heating element in this state to the total number of temperature measurement units, and measure the percentage of the number of temperature measurement units that have not reached the set temperature at five different times Percentage of the number of units, average five values, the average is the s...

Embodiment 3

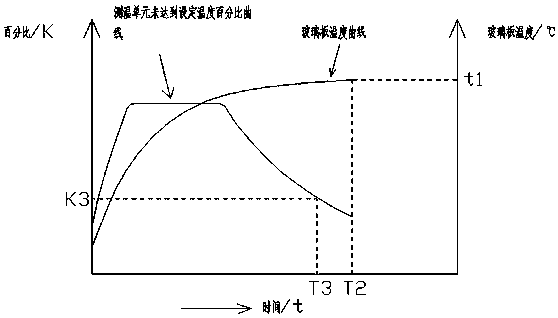

[0038] Such as image 3 As shown, the executive mechanism is a control mechanism that controls the opening of the cooling fan or changes from an idle state to a working state. The control process of the control method of the present invention is as follows:

[0039] First determine the heating furnace to be used, adjust the working temperature of the heating furnace according to the type of glass plate to be heated (such as low-emissivity coated glass, clear glass) and thickness information, and run the heating furnace at room temperature without load to reach the working temperature. Monitor the percentage of the number of temperature measuring units that have not reached the set temperature of the heating element in this state to the total number of temperature measurement units, and measure the percentage of the number of temperature measurement units that have not reached the set temperature at five different times. The percentage of the number of temperature units, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com