Intelligent pedestal pan high-pressure forming system

A high-pressure forming, intelligent seat technology, applied in ceramic forming machines, ceramic forming workshops, manufacturing tools, etc., can solve the problems of increased operation risk, reduced equipment operation efficiency, low production efficiency, etc., to reduce material and financial resources. The effect of waste, reducing the difficulty of equipment development and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

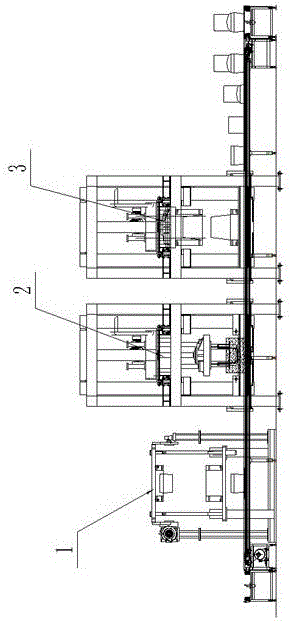

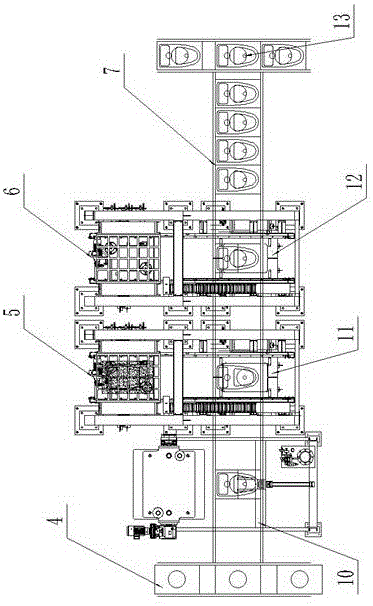

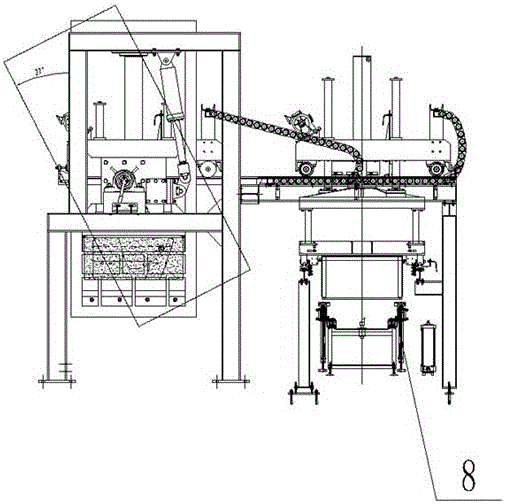

[0015] Such as Figure 1 to Figure 4 As shown, this specific embodiment adopts the following technical solutions: a high-pressure forming system for intelligent toilet seat, including a seat ring forming system, a liner forming system, an outer cover forming system and a green body bonding system; the seat ring forming system includes a seat Ring forming machine 1 and ring stripping mechanism 9; the liner forming system includes stripping trolley 2, liner forming machine 5, lifting stripping mechanism 8 and liner side mold opening mechanism 11; the outer casing forming The system includes a blanking trolley 2 3, a jacket forming machine 6, and a lifting and blanking mechanism 2 12; the blank bonding system includes a pallet conveying line 4, a bonding conveying line 7, a pallet conveying line 10 and a blank conveying Line 13; the specific connection relationship of the seat ring forming system, the liner forming system, the overcoat forming system and the green body bonding sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com